- Product Details

- {{item.text}}

Quick Details

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.15 - 2 mm

-

Heating Power (kW):

-

112 kW

-

Air Comsumption(L/min):

-

10 L/min

-

Water Comsumption(L/min):

-

10 L/min

-

Place of Origin:

-

China

-

Brand Name:

-

HW Machine

-

Voltage:

-

380V 50hz

-

Dimension(L*W*H):

-

9000mm*2300mm*2500mm

-

Weight (T):

-

12 T

-

Power(KW):

-

150KW

-

Application:

-

Plastic Products

-

Suitable material:

-

PET PS PVC PP

-

Forming Area:

-

710*850*

-

Max Forming Depth:

-

120mm

-

Air Consumption:

-

0.8m3/min

-

Color:

-

Customized Color

-

Control:

-

PLC+Touch Screen

-

Delivery Time:

-

60 Working Days

-

Machine Name:

-

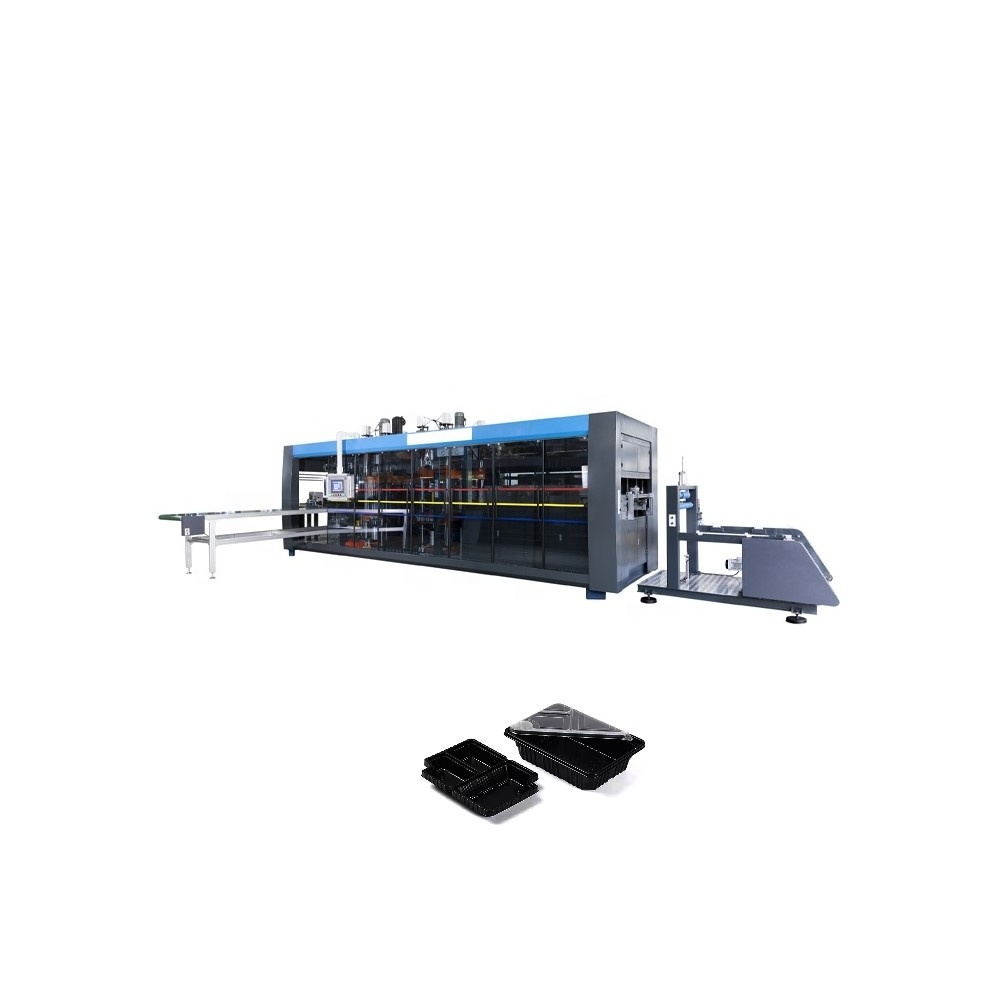

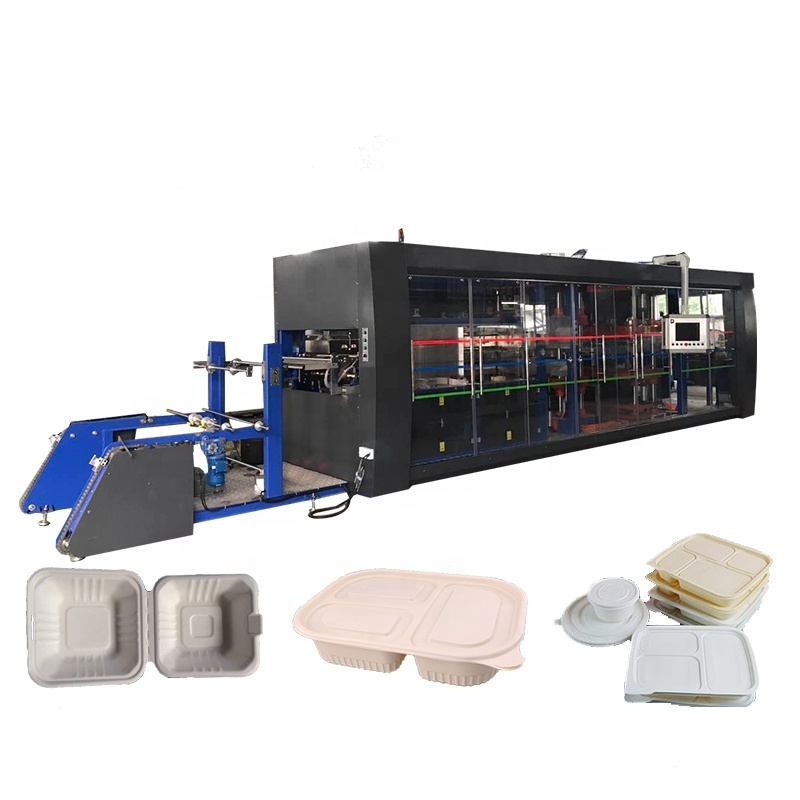

Fully Automatic Plastic Products Forming Machine

-

Model:

-

HW-7185 Thermoforming Machine

-

Marketing Type:

-

Hot Product

Quick Details

-

Max.Forming Height(mm):

-

120 mm

-

Forming Width (mm):

-

740 mm

-

Forming Length (mm):

-

850 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.15 - 2 mm

-

Heating Power (kW):

-

112 kW

-

Air Comsumption(L/min):

-

10 L/min

-

Water Comsumption(L/min):

-

10 L/min

-

Place of Origin:

-

China

-

Brand Name:

-

HW Machine

-

Voltage:

-

380V 50hz

-

Dimension(L*W*H):

-

9000mm*2300mm*2500mm

-

Weight (T):

-

12 T

-

Power(KW):

-

150KW

-

Application:

-

Plastic Products

-

Suitable material:

-

PET PS PVC PP

-

Forming Area:

-

710*850*

-

Max Forming Depth:

-

120mm

-

Air Consumption:

-

0.8m3/min

-

Color:

-

Customized Color

-

Control:

-

PLC+Touch Screen

-

Delivery Time:

-

60 Working Days

-

Machine Name:

-

Fully Automatic Plastic Products Forming Machine

-

Model:

-

HW-7185 Thermoforming Machine

-

Marketing Type:

-

Hot Product

Products Description

HW-7185 Full-Automatic 3 Stations Thermoforming Machine

Feature:

HW-7185 high-efficiency program-controlled plastic air pressure thermoforming machine, applying the latest international plastic sheet forming technology, is integrated design of machine, electricity and gas, using microcomputer and industrial control programmable PLC control, the entire system HMI. The square tunnel-type imported radiant heater, both concave and convex molds can be formed, laser blade punching, and its process flow: heating, forming, punching, stacking counting and other main multi-station production lines.

Usage:

Suitable for the molding of HIPS, PS, PP, PVC, PET, etc. plastic sheets, processing high transparency, high stretch, shallow stretch, round, square, irregular, up and down bidirectional stretching , Flanging and other products, producing various boxes, dishes, trays, bowls, covers, industrial packaging, food packaging, cosmetics packaging and other packaging and other plastic products.

|

Main Electronic Component

|

Brands

|

|

AC Contactor

|

Schneider

|

|

Vacuum Pump

|

Germany Weili 100M3/HR

|

|

The Electromagnetic Valve

|

Japan CKD, SMC, Taiwan Goldware, Xin Gong

|

|

Positive Pressure Valve

|

Japanese SMC

|

|

Proximity Switch

|

Japan Omron

|

|

Bearing

|

Japan NSK

|

Details Images

Name:Cutting Station

The cutting station drive is driven by a full servo motor, which can effectively increase the production rate of the machine. While ensuring uniform cutting, the production speed of the machine can be faster, and the effective production efficiency can reach 30 cycles per minute at the fastest. (The production speed of the machine depends on the sheet produced and its thickness

Name: 3 Stations Machine

Heating Zone:

2500mm

Forming Station:

710×850mm

Cutting Station:

80-100T Power

Name: 4 Stations Machine

Heating Zone:

2500mm

Forming Station:

710×850mm

Punching Station:

60T Power

Cutting Station:

80-100T Power

Name: Molds

Model: Cutting Upper Mold; Cutting Lower Mold; Forming Lower Molds; Forming Upper Molds

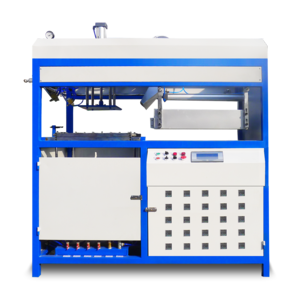

Name: 10HP Chiller

Nominal Cooling Capacity:

27500 Kcal/h

Compressor Power:

3.75kw*2

Chilled Water Pipe Diameter:

15 inch

Cooling Air Volume:

42.3m³/h

Capacity:

3.80m³/min

Cooling Method:

Air Cooling

Oil Content of Discharged Air:

Less than 3 ppm

Why Choose Us

●15+ Years Industry Experience

Our Company

Polynk is a professional platform in plastic & rubber industry invested by Jwell, supported by many famous Chinese plastic manufacturers. In order to meet more customers’ production demands, we are devoted to providing one-stop service, not only plastic machines, but also other auxiliary equipment and raw materials.

With more than 15 years experiences in plastic & rubber industry, Polynk has built a professional team to provide our customers much professional suggestions and high-performance cost products.

With more than 15 years experiences in plastic & rubber industry, Polynk has built a professional team to provide our customers much professional suggestions and high-performance cost products.

● Strong Team Service Ability

What can Polynk do for you?

● Provide you more powerful industry suppliers

● Bring you latest industry information through videos

● Visit and inspect your interested factory

●Track industry hot topics and explore new development direction

● Professional Technology Support

● Local After-sale Service

Polynk specializes in providing outstanding after-sale services for our foreign customers. In Europe, Middle East and Southeast Asia, we can send our reliable and rich experienced partners to your factories who can train your engineers and solve machines’ problems in time.

Meanwhile, Polynk has a global extrusion engineer certification team for all engineers to communicate with each other.

Meanwhile, Polynk has a global extrusion engineer certification team for all engineers to communicate with each other.

●

Abundant Certifications

●

Rich Exhibition Experience

Polynk has taken part in many industry exhibitions like Chinaplas, or other foreign exhibitions in Turkey, Egypt, Mexico, Russian and so on. From these exhibitions, we are trying to find reliable suppliers for our customers and explore more latest industry information. We always focus on plastic industry and try our best to help our customer to solve their difficulties.

On October, we already has a booth on K show. If you are interested in our company, welcome to our booth.

Each year, we hold some meetings about plastic industry. We will invite those companies to take part in our meeting to discuss industry topics. It is also a method to expand our network, to know more people.

● Powerful Precision Processing Equipment

● Strong Product Packaging and Fast Delivery Time

FAQ

Q1. What about the payment way?

A1. By TT, L/C at sight or Alibaba trade assurance. 30% down payment should be paid after contract is valid, 70% balance should be paid before shipment.

Q2. Installation and stuff training available from you?

Q2. Yes, we have rich engineers in Europe which can send to your factory and train your workers. Also we can online guide your members.

Q3. How long is the guarantee?

A3. We offer you high quality machines with 12 months guarantee and reply you as soon as possible within 12 hours.

Q4. If the machine some parts is broken one day, how can we get help from you?

A4. We will send you spare parts free of charge If they are in warranty, not including easy-broken parts. For easy-broken parts, we will only charge cheap costs.

Q5.How does your factory do regarding quality control?

A5.We have passed the ISO9001:2000 Quality Management System and CE certificate and we have a special QC department in charge of

products' quality. If you also need other certificates, we also can help to apply.

Q6. What is your packaging?

A6. Our conventional packaging is: Wrap the plastic film around the machine,and then put the machine in a wooden box.

Q7. How can we check the machines before delivery?

A7. We can provide online checking when testing the machine on site. We will take and prepare detailed testing videos for your checking before the delivery. We accept third-party testing. Except above points,we will provide detailed testing report.

Q2. Installation and stuff training available from you?

Q2. Yes, we have rich engineers in Europe which can send to your factory and train your workers. Also we can online guide your members.

Q3. How long is the guarantee?

A3. We offer you high quality machines with 12 months guarantee and reply you as soon as possible within 12 hours.

Q4. If the machine some parts is broken one day, how can we get help from you?

A4. We will send you spare parts free of charge If they are in warranty, not including easy-broken parts. For easy-broken parts, we will only charge cheap costs.

Q5.How does your factory do regarding quality control?

A5.We have passed the ISO9001:2000 Quality Management System and CE certificate and we have a special QC department in charge of

products' quality. If you also need other certificates, we also can help to apply.

Q6. What is your packaging?

A6. Our conventional packaging is: Wrap the plastic film around the machine,and then put the machine in a wooden box.

Q7. How can we check the machines before delivery?

A7. We can provide online checking when testing the machine on site. We will take and prepare detailed testing videos for your checking before the delivery. We accept third-party testing. Except above points,we will provide detailed testing report.

Hot Searches