- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Customized

-

Weight:

-

5000 kg

-

Dimension(L*W*H):

-

Customized

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts

-

Name:

-

silica sand filter press

-

Type:

-

Sludge Filter Press

-

Application:

-

Sewage Dewatering

-

Description:

-

Dehydration

-

Material:

-

Stainless Steel 304/316

-

Filtering area:

-

10-1000 Square Meters

-

Product name:

-

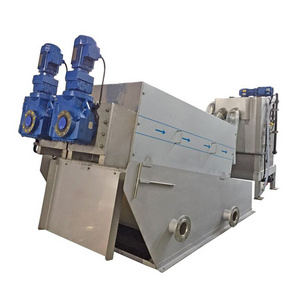

Multi-plate Screw Filter Press

-

Function:

-

Liquid Solid Separation

-

Filter plate material:

-

316L Stainless Steel

-

Certification:

-

ISO9001&CE

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jincheng

-

Voltage:

-

Customized

-

Power:

-

Customized

-

Weight:

-

5000 kg

-

Dimension(L*W*H):

-

Customized

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts

-

Name:

-

silica sand filter press

-

Type:

-

Sludge Filter Press

-

Application:

-

Sewage Dewatering

-

Description:

-

Dehydration

-

Material:

-

Stainless Steel 304/316

-

Filtering area:

-

10-1000 Square Meters

-

Product name:

-

Multi-plate Screw Filter Press

-

Function:

-

Liquid Solid Separation

-

Filter plate material:

-

316L Stainless Steel

-

Certification:

-

ISO9001&CE

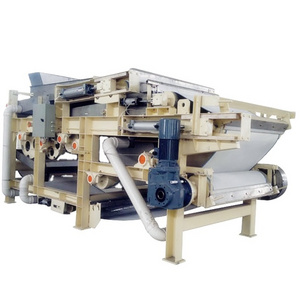

Waste water treatment filter press High Efficiency Dehydrator Hydraulic Filter press

1.Product description

Henan Jincheng Filter Equipment Co., Ltd is a professional manufacturer of filtering equipments. We are one of the key enterprises specializing in manufacturing filter press. Our products range covers series of plate and frame filter press, chamber filter press, belt vacuum filter press, membrane filter press, centrifuge, shale shaker, industrial pumps, deep cone thickener, flotation column, etc.

The manual filter press is a kind of intermittent operation of the pressurized filtration equipment which is suitable for the small scale of testing.

2.Usage of the

Automatic Hydraulic filter press

It is widely used in coal washing , Oil, chemicals, dyes, metallurgy, medicine, food, alcohol and other fields, but also for textile, printing and dyeing, pharmaceutical, paper, leather and other industrial waste water and urban sewage treatment and other areas that need to be solid-liquid separation.

3. Details of the

Automatic Hydraulic filter press

|

Model

|

Filtering area

|

No,of plate

|

Volume of chamber

|

Filtering pressureMpa

|

|

XMY50/870-30

|

50

|

37

|

745

|

0.5-1.6

|

|

XMY60/870-30

|

60

|

45

|

900

|

0.5-1.6

|

|

XMY70/870-30

|

70

|

53

|

1053

|

0.5-1.6

|

4.Functions of Automatic Hydraulic filter press

You can choose different systems based on your requirements, for example , free-flow or under flow, manual or automatic ,washing or with belt conveyor;

5.Working principle

When the sludge filter press works, all the filter plates are pressed between the movable head plate and the fixed tail plate, so that the adjacent filter plate is formed with

a sealed filtering chamber around. After all the filter chambers are filled with pulp, the pressure filtration process begins, and

the slurry is separated from the pulp by the feed pump.

The solid particles are left in the filter chamber due to the barrier of the filter cloth, and the filtrate is discharged through the filter cloth along the drainage channel on the filter plate,

and the filtrate is not discharged, that is, the dewatering process is completed. At this point, the material can be stopped

and the head plate is returned to the original position.

6.The filtering effect and case of our factory

7. Customer visiting and exhibitions

we have export to a lots of countries around the world, for example, USA, Russia, South Africa, India, Iraq,German,Brazil,Sri Lanka and so on

8. Our workshop

9.Package and transport

10 Certificate

11 Guarantee

Service:

1. we have professional technical team to offer advice before ordering;

2. There have technical support service online;

3.We will offer video or instruction to help install the machine;

4.If necessary, the engineer will door to door for debugging the machine;

5.Electrical elements is 1 year warranty(Except quick-wear parts)

6.Frame is 5 years warranty.

12 FAQ

Q1: Do you provide on-site installation service?

Yes, we will provide on-site installation, debugging, training and other services.

Q2: Why did I choose your product?

We have advanced technology, can provide cheaper prices, better product quality, higher performance, lower maintenance costs and perfect after-sales service.

Q3: How long does it usually take for your products to ship?

Generally, the delivery time is two to three weeks.

Q4: Do you support OEM service?

Yes, we fully support OEM services and welcome you to customize our products.

Q5: What if the product received has been damaged?

Please rest assured that within 15 days after receipt of the goods, we will provide no reason to return or exchange services.

Q6: Can I get a cheaper price?

Of course, please contact us, we can give you a cheaper price.

Q7: What if the product breaks down in the future?

Don't worry, we offer a very long warranty, and we will send our engineers to repair it, or even we can replace it.

Hot Searches