- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

80

-

Weight (KG):

-

1600 KG

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yuanda

-

Voltage:

-

220v/380V/415V/440V

-

Dimension(L*W*H):

-

Referring

-

Power (kW):

-

11 kW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

capacity:

-

2L-8000L

-

model:

-

single layer or double layer

-

quality:

-

304/316 SS or carbon steel

-

experience:

-

many years

-

use for:

-

silicon rubber,dough,resin,additive

-

discharge way:

-

hydraulic tilt,screw extruding,bottom valve

-

heating:

-

option

-

vacuum:

-

option

-

certification:

-

can provide CE

Quick Details

-

Barrel Volume (L):

-

150 L

-

Max. Loading Volume (L):

-

80 L

-

Range of Spindle Speed(r.p.m):

-

27 - 31 r.p.m

-

Max. Loading Capacity:

-

80

-

Weight (KG):

-

1600 KG

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yuanda

-

Voltage:

-

220v/380V/415V/440V

-

Dimension(L*W*H):

-

Referring

-

Power (kW):

-

11 kW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

capacity:

-

2L-8000L

-

model:

-

single layer or double layer

-

quality:

-

304/316 SS or carbon steel

-

experience:

-

many years

-

use for:

-

silicon rubber,dough,resin,additive

-

discharge way:

-

hydraulic tilt,screw extruding,bottom valve

-

heating:

-

option

-

vacuum:

-

option

-

certification:

-

can provide CE

Product Description

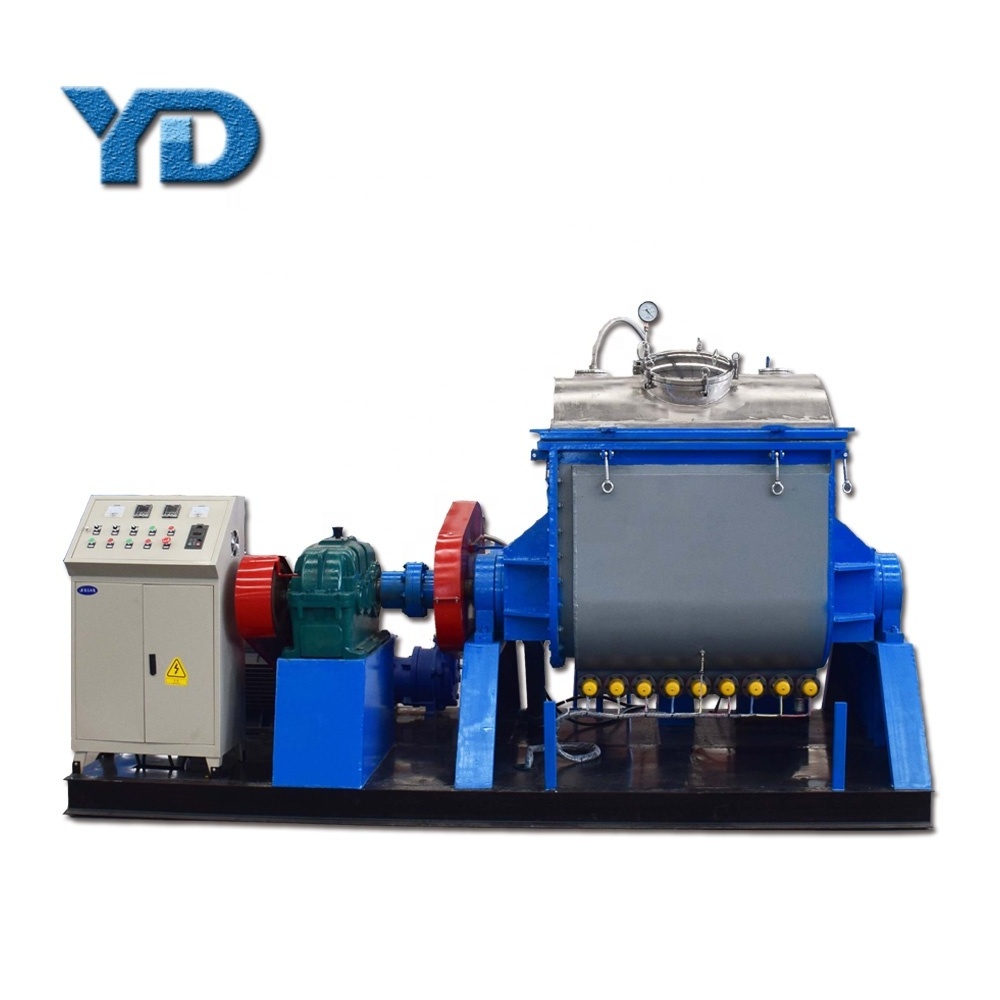

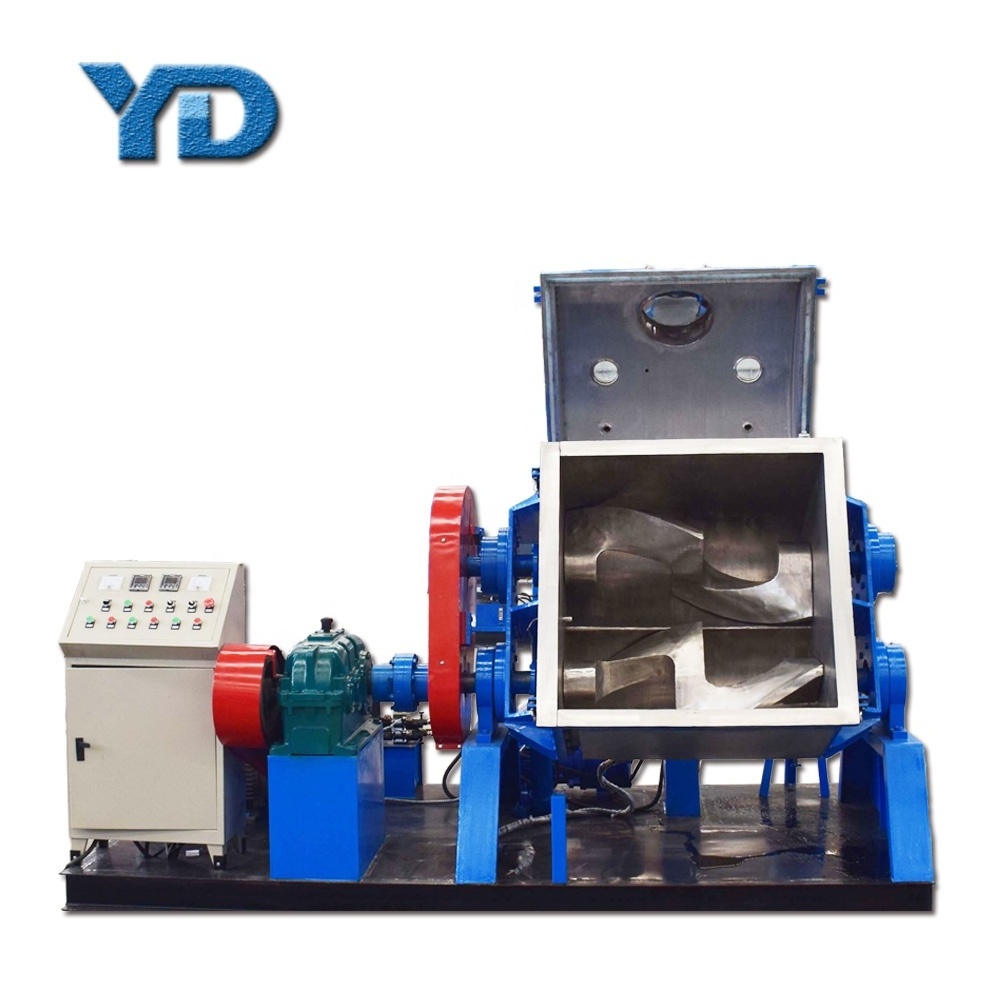

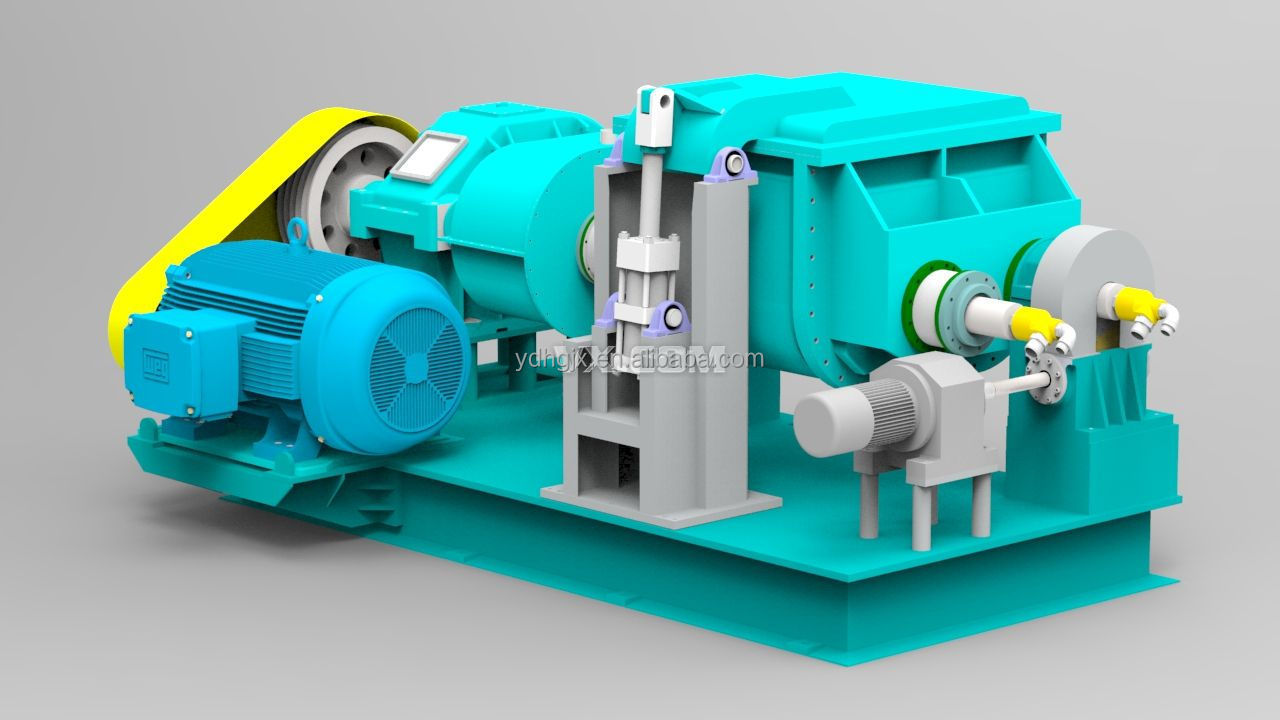

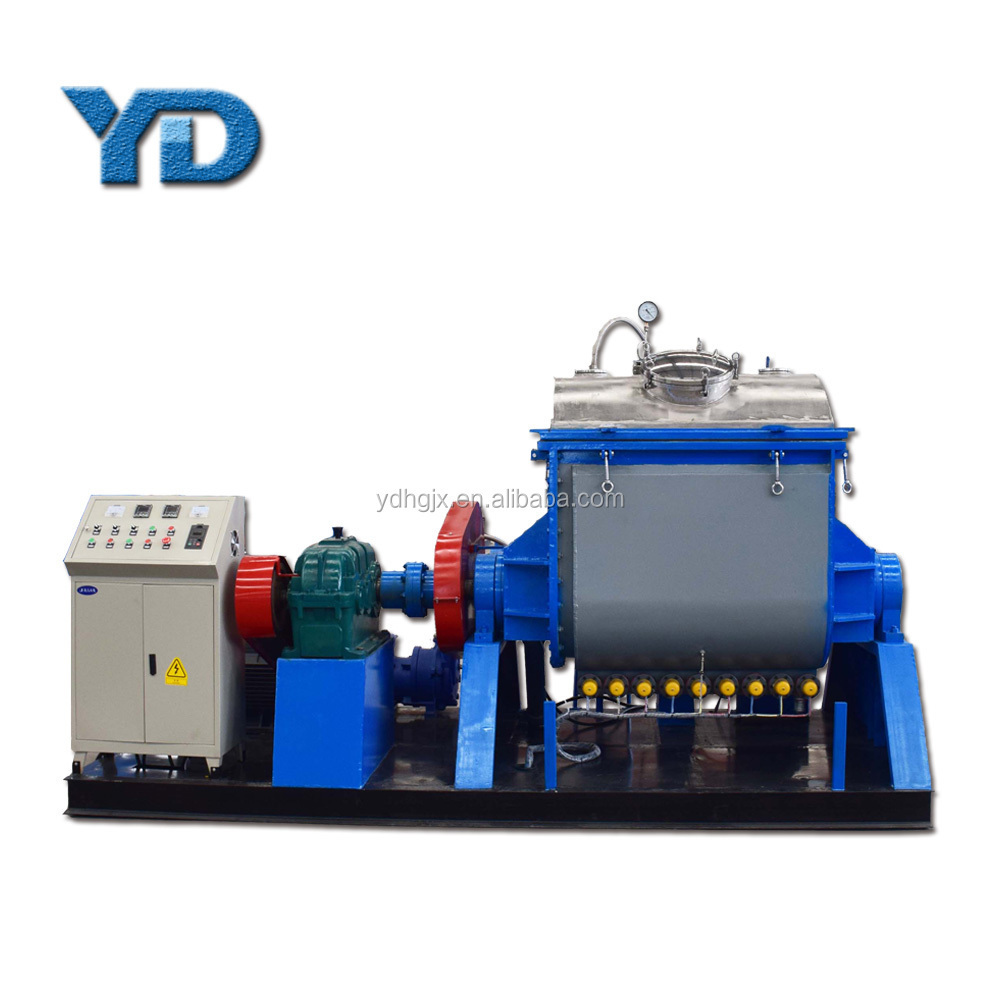

This machine is Mesa Structure,horizontal and double blades type,(Sigma “Z” blade),with jacket which can be added water for cooling.

All the Material which contact the product is SS304 or SS316L(can be customized);

The Kneading Pot through grinding and polishing near to the Mirror,Polish degree is 0.8;

It is special equipment to mix,knead,crush,disperse,polyermerzing high viscosity material,with uniform mixing,without dead angle,high kneading efficiency feature.

1)It can be widely used in BMC/DMC,High viscosity Silicone Sealant, Silastic,GlassCement,Chewinggum,Cellulose,Battery,Printing-ink,Dye,Resin,Plastic,Cosmetic,Pigment.

2)Material is mainly Stainless Steel or Carbon Steel.

3)Heating way with Steam Heating,Oil heating Electric heating.Water cooling system.

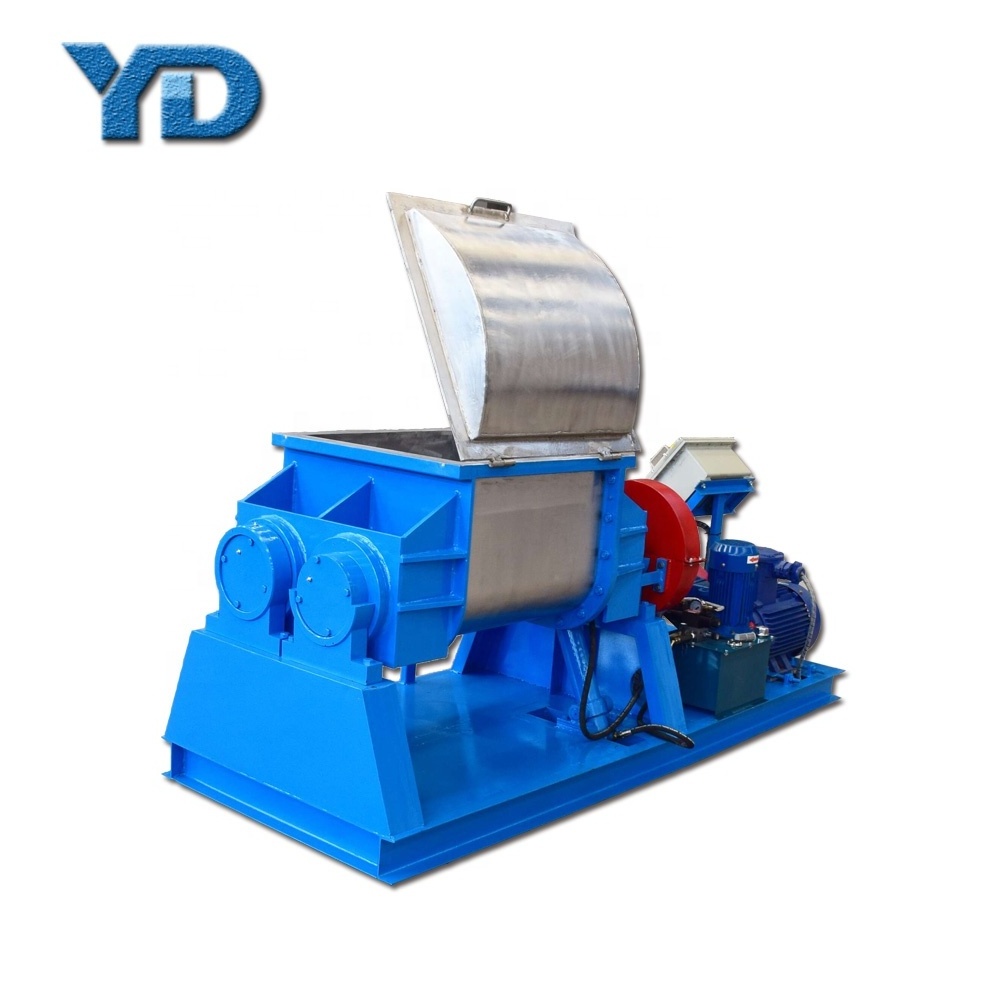

4)Discharging way is mainly Hydraulic Dumping Tilting Discharge,Manual Tilting Discharge,Screw Extruder Discharge.

5) Main Type:Ordinary,Vacuum Type.

6) different capacity :from Laboratory Scale to Mass Production.

All the Material which contact the product is SS304 or SS316L(can be customized);

The Kneading Pot through grinding and polishing near to the Mirror,Polish degree is 0.8;

It is special equipment to mix,knead,crush,disperse,polyermerzing high viscosity material,with uniform mixing,without dead angle,high kneading efficiency feature.

1)It can be widely used in BMC/DMC,High viscosity Silicone Sealant, Silastic,GlassCement,Chewinggum,Cellulose,Battery,Printing-ink,Dye,Resin,Plastic,Cosmetic,Pigment.

2)Material is mainly Stainless Steel or Carbon Steel.

3)Heating way with Steam Heating,Oil heating Electric heating.Water cooling system.

4)Discharging way is mainly Hydraulic Dumping Tilting Discharge,Manual Tilting Discharge,Screw Extruder Discharge.

5) Main Type:Ordinary,Vacuum Type.

6) different capacity :from Laboratory Scale to Mass Production.

|

Model NH-5 NH-40 NH-100 NH-300 NH-500 NH-1000

Volume(L) 5 40 100 300 500 1000

PaddleAgitator(rpm)

33,23 45,23 35,22 37,21 37,21 35,25

Major motor power(kw) 0.75 2.2 4,5.5 7.5,11 15,18.5 22,30,37,45 22,30,37 45

Form of heating Steam:Pressure(MPa) 0.3

Electric heating:Power(kw) 1 4 4 6 16.2 25 32.4 40 Degree of vacuum(MPa) 0.094(vacuum kneader)

Pressure(MPa) 0.45(pressure kneader) 0.35(pressure kneader)

Weight(kg) 300 560 1250 1600 3000 4500 5800 6500

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Direction for use

Normal use and reasonable management are the key to ensure safety working and smooth production of kneader, so end-user must pay more attention on it.

Safety operation rules should be made as per the requirement of production process and technical function of kneader, meanwhile maintain a kneader regularly. The maintenance contents as below:

5.1 Index of operation process and the highest temperature.

5.2 Operation way: startup and shutdown jar cover up & down, turning jar and safety attention matters.

5.3 The projects and parts which should be paid more attention during running, and abnormal occurrence maybe happened and preventing way.

5.4 The schedule of technical maintenance for vacuum box shaft seal structure.

5.5 Operators must pass technical training, and operate a machine alone only after passing technical training, operation against rules is forbidden.

-

Description of application effect

-

For stable quality of product, in order to assure kneader always in good working condition, fully run its performance, try to prolong its service life, must do technology maintenance carefully.

Technology maintenance of every shift:

1,Check if dirt attached on every part, check if fixed screws and nuts of each connection parts are loose.

2,Check if oil, gas and water are leaking. 3,Check if all the pipeline, valve, seal and especially all hoses are damaged.

4,Fill grease to each lubricating nozzle. 5,Check oil level and oil quality of hydraulic oil tank, decelerator, opposite running gear case.

6,Check if air compressor works well and air pressure is normal (some models)

7,Check if hand valve of cooling water and heat transfer oil is opened.

8,Check the tightness degree of vee belt. 9,Check if overtravel-limit switch of electrical automatic control is matching.

10,Check every catanator and electrical equipment.

11,Check vacuum degree in vacuum box, vacuum degree in tank.(for some kneaders )

12,Check if any obvious dirt in the material in the gap between stirring shafts.

13, Check if there is any dirt inside of vacuum box(for some kneaders )

Detailed Images

Kneader is a high-efficiency mixing equipment, mainly used in milling, kneading, crashing, dispersing and recombining all kinds of high viscosity and super high viscosity elastic plastic material.

Kneader is widely used in the industries such as high viscosity sealant, silicone rubber, neutral and acetoxy silicone sealant, CMC, battery, ink, pigment, medicine, resin, plastic, rubber and cosmetics.

Related Products

Packing&Shipping

After Sales Service

Services:

1.Online support;

2.Video technical support;

3.Field maintenance and repair service;

4.Spare parts;

Company Introduction

Located in Laizhou city, the intersection of Yantai, Qingdao and Weifang, the Laizhou Shahe Yuanda Chemistry & Machinery Factory enjoys the beautiful and rich Bohai Bay. Be with convenient transportation as well as favorable geographical location, it is a perfect place for both trade and office place.

We are an integrative enterprise incorporated with scientific research development, manufacturing, marketing, and sales-after services.

We are an integrative enterprise incorporated with scientific research development, manufacturing, marketing, and sales-after services.

Featuring reasonable structure, durability, easy operation and maintenance, with a number of technology management

specialists who have many years experiences in machinery design and development, we are committed ourselves to satisfy various demands from our customers. We are rewarded as City-Level Advance Enterprise; Superfine Reputation Enterprise and reached the ministrys quality control standard.

specialists who have many years experiences in machinery design and development, we are committed ourselves to satisfy various demands from our customers. We are rewarded as City-Level Advance Enterprise; Superfine Reputation Enterprise and reached the ministrys quality control standard.

Our products have been distributed all around the country and obtained high credit from our costumers.

Led by our director, Liu Xiaobin, we eliminated any worries from our customers by building and completing a full quality

guaranteed system, which covering manufacturing, marketing, and after-sale service. Factory director, Liu Xiaobin, together with the whole staff welcomes all friends from all field, and looks forward to the most sincerely co-operation. Together lets create a splendent future in the 21st century!

Led by our director, Liu Xiaobin, we eliminated any worries from our customers by building and completing a full quality

guaranteed system, which covering manufacturing, marketing, and after-sale service. Factory director, Liu Xiaobin, together with the whole staff welcomes all friends from all field, and looks forward to the most sincerely co-operation. Together lets create a splendent future in the 21st century!

Our Services & Strength

We have do this machine produce more than 20 years,have rich experience and mature technical to design and produce this machine,any detail requirment we can as discuss to make.

FAQ

Q: Can you send the formula for the products we want to make?

A: Our machines can be used for many kinds of product making, such as Resin, Paint, Adhesive, Cosmetic, Food, Chemicals. There are many kinds of these products, so it's impossible for us to know all the formulas and technologies. We can assist you to find the raw material list you need, and after you place order with us, we can help you to find formula and technology, there will be engineers to teach you how to make the product, and the cost will be on your account.

Q: Do you have machines in stock?

A: Yes, but just the small-scale machines. Machines are different with other products, most of the large-scale machines are designed according to our customers' requirements, different customers have different production requirements, so the technical parameter is different for most machines. On the other hands, most of the our machines will cover a large area, so once the machines are finished, we will effect shipment after QC.

Q: Why does it take at least 20 days to finish the machine?

A: Once receipt the deposit from you, we will design the drawings and make out the list of the materials and accessories for the production. Once the drawings are finished, our workers will start the production, from welding, polishing, assembling, debugging, detection and so on. After finish, they need time to check the machines, if found any possible defect parts, they will return to the production until every part is 100% approved.

Q: Can you send the detailed drawings of the machine to us before we place order?

A: We can send you a draft drawing of the machines, and after you place order and pay the deposit, our engineer will design the specific technical parameters fo you and send you the detailed drawings. Once you confirm without questions, we will put it into production.

Q: Can we pay the balance after we receive the machines and test without problems?

A: It's unnessary to worry about the quality of our machines, we are confident in that. After the machine is finished, we can

install and test the machine for you (if you can not come to our factory, we can record a vedio and send to you). Only after you check without problems, we will effect shipment.

Hot Searches