- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2.2kw

-

Weight:

-

400

-

Dimension(L*W*H):

-

800*700*1600mm

-

After Warranty Service:

-

Field maintenance and repair service

-

local Service Location:

-

None

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Function:

-

liquid liquid solid separator

-

Material:

-

carbon steel or stainless steel

-

Discharge:

-

manual

-

Capacity:

-

200-1200L/h

-

Bowl volumn:

-

5.5L

-

Item:

-

tubular bowl centrifuge

-

Bearing:

-

SKF Bearing

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

WANDA

-

Voltage:

-

customized

-

Power:

-

2.2kw

-

Weight:

-

400

-

Dimension(L*W*H):

-

800*700*1600mm

-

After Warranty Service:

-

Field maintenance and repair service

-

local Service Location:

-

None

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Function:

-

liquid liquid solid separator

-

Material:

-

carbon steel or stainless steel

-

Discharge:

-

manual

-

Capacity:

-

200-1200L/h

-

Bowl volumn:

-

5.5L

-

Item:

-

tubular bowl centrifuge

-

Bearing:

-

SKF Bearing

Product Advantages

Structures and properties:

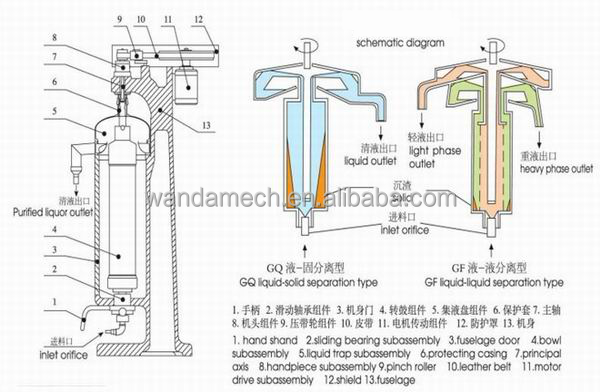

The separator consists of machine body, driving part, bowl, liquid collecting pan and liquid-in bearing seat etc.

The material is sprayed onto the bowl from the inlet on the bottom and strong centrifuge force is formed when the bowl rotates with the material and that makes the material flow upper along the wall of the bowl and then separated because of the different gravity by the centrifuge force.

GQ-for clarification: Heavy solid is deposited on the inner wall of the bowl,and forms the sludge. And it will be discharged by manual after the machine stops. The clear liquid flows out of outlet from the top of the bowl.

The motor connect with the big pulley and delivery the power to the spindle through the belt, tensioner and small pulley and rotate with the bowl in high-speed as the clockwise.

GF model is a separating equipment where there the liquid phase of large density is formed into outer ring and the liquid phase of small density is shaped into inner ring, to flow to the top of bowl, to be discharged out from their respective liquid outlets.

The micro solids settle on the wall of the bowl and are to be manually dumped after the machine is shut down.

The material is sprayed onto the bowl from the inlet on the bottom and strong centrifuge force is formed when the bowl rotates with the material and that makes the material flow upper along the wall of the bowl and then separated because of the different gravity by the centrifuge force.

GQ-for clarification: Heavy solid is deposited on the inner wall of the bowl,and forms the sludge. And it will be discharged by manual after the machine stops. The clear liquid flows out of outlet from the top of the bowl.

The motor connect with the big pulley and delivery the power to the spindle through the belt, tensioner and small pulley and rotate with the bowl in high-speed as the clockwise.

GF model is a separating equipment where there the liquid phase of large density is formed into outer ring and the liquid phase of small density is shaped into inner ring, to flow to the top of bowl, to be discharged out from their respective liquid outlets.

The micro solids settle on the wall of the bowl and are to be manually dumped after the machine is shut down.

Main Features:

Strong in separation, simple in structure, convenient in operation and maintenance, low in consuming power, small in ground, high in speed ,strong in separation factor, small in noise, adaptive in material with high or low temperature.

Scope of Application

|

GQ-clarification

|

It is mainly used for separating all kinds of suspension difficult to be separated, especially suitable for separation of solid-liquid suspension with light concentration, heavy viscosity, fine particles and very small differential gravity of the two phases.

For example clarifying all kinds of glucose chlorhexidine, malic acid, oral solution, radix soghorae tonkinensis,coal tar and graphite; extracting protein,algae, saponin, pectin, sirup; blood separation and all kinds of glucose; refining paint, resin, and latex solution. |

|

GF

|

It is used for separating various emulsion, especially adaptable for liquid-liquid separation with slight gravity difference and liquid-liquid-solid separation with a little foreign matter, such as separation of various oil and micropowder, extract liquid from plants, separation of plasma and cell, separation of milk cream.

|

Working principle

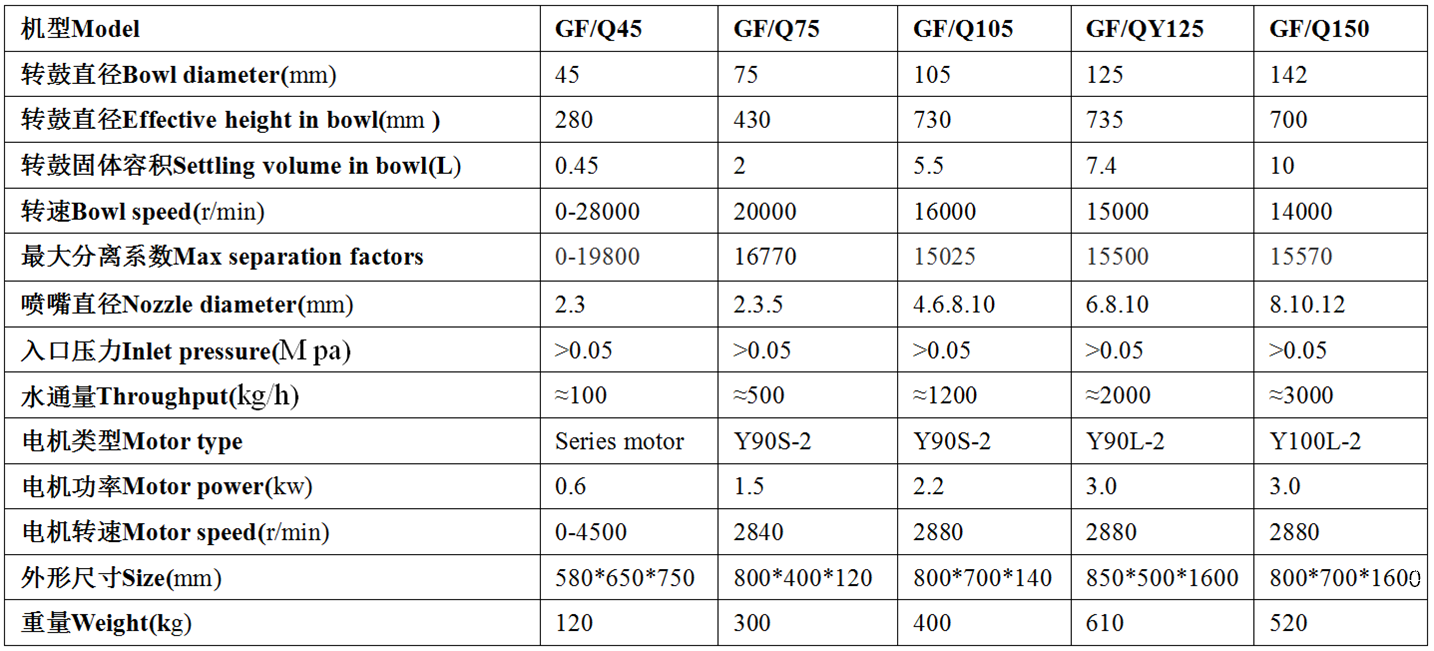

Product Parameters

Product More Pictures

Remark: The most import part of tubular centrifuge is the bowl part, some pictures as follows:

Some import spare parts:

Hot Searches