- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HC-ROD

-

Particle:

-

0.4μm~3.2μm

-

Product name:

-

YG6 2.5mm Grinding Solid Round Cemented Tungsten Carbide Rods

-

Material:

-

Tungsten Carbide

-

Grade:

-

YL10.2/ YG10X/ Customized according to your requirements

-

Usage:

-

for making cutting tools, such as end mills, drills, reamers, burs.

-

Hardness:

-

HRA 89~94

-

TRS:

-

3600~4200 MPa

-

Surface Treatment:

-

Polished / Grinding / Blanks

-

Diameter:

-

0.3~35mm

-

Tolerance:

-

±0.001mm

-

Certificate:

-

ISO9001:2015

Quick Details

-

Alloy Specification:

-

K25-K35

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

HAO Carbide

-

Model Number:

-

HC-ROD

-

Particle:

-

0.4μm~3.2μm

-

Product name:

-

YG6 2.5mm Grinding Solid Round Cemented Tungsten Carbide Rods

-

Material:

-

Tungsten Carbide

-

Grade:

-

YL10.2/ YG10X/ Customized according to your requirements

-

Usage:

-

for making cutting tools, such as end mills, drills, reamers, burs.

-

Hardness:

-

HRA 89~94

-

TRS:

-

3600~4200 MPa

-

Surface Treatment:

-

Polished / Grinding / Blanks

-

Diameter:

-

0.3~35mm

-

Tolerance:

-

±0.001mm

-

Certificate:

-

ISO9001:2015

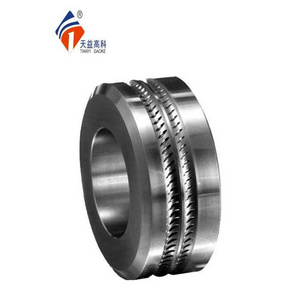

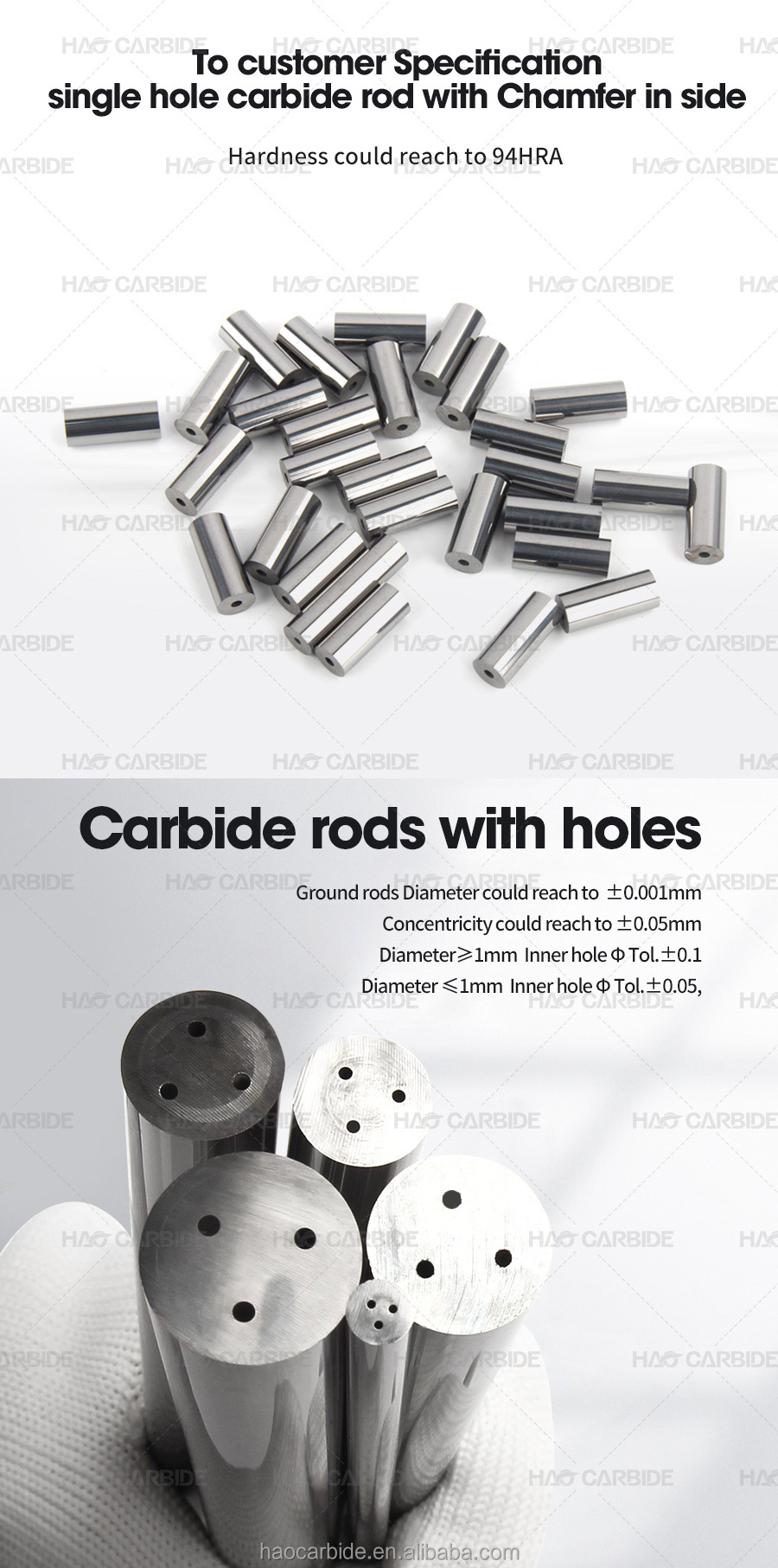

High Quality Cemented Carbide Rod Hard Alloy Nozzle in Stock

Advantages of tungsten carbide rods

1. Using over 99.95% high purity tungsten carbide powder, it has a better strength and hardness combined with a longer service life than the normal one.

2. Using ultra-fine grain size of tungsten carbide powder to produce, Hardness can reach to HRA 93.6, Bending strength can reach to 4000 N/mm².

3. Tolerance can reach to ±0.001 mm, straightness can reach to ±0.02 mm.

|

Grade

|

Grade ISO

|

Cobalt content (%)

|

Grain size of WC (μm)

|

Hardness (HRA)

|

Density (g/cm3)

|

TRS (N/mm2)

|

||||||

|

JZ06U

|

K05-K10

|

6

|

0.4

|

94

|

14.85

|

≥4000

|

||||||

|

JZ08U

|

K10-K20

|

8

|

0.4

|

93.6

|

14.65

|

≥4000

|

||||||

|

JZ12U

|

K20-K40

|

12

|

0.4

|

92.5

|

14.15

|

≥4200

|

||||||

|

JZ12U-T

|

K20-K40

|

12

|

0.4

|

93

|

14.2

|

≥3800

|

||||||

|

JZ10S

|

K20-K40

|

10

|

0.6

|

92.3

|

14.4

|

≥3900

|

||||||

|

JZ10F

|

K20-K40

|

10

|

0.8

|

91.8

|

14.4

|

≥3800

|

||||||

|

JZ07C

|

K05

|

7

|

1.0

|

92

|

14.8

|

≥3000

|

||||||

|

Tungsten Cemented Carbide Ground Rod Grade Application

|

|

|

|

|

|

|

||||||

|

JZ06U

|

Be suitable for processing aluminum magnesium alloy, glass fiber, carbon fiber, wood, hard plastic, etc. Recommend for making micro tools and drills.

|

|

|

|

|

|

||||||

|

JZ08U

|

Be suitable for processing resin, wood, titanium alloy, stainless steel, copper-aluminum alloy, composite material. Recommend making high speed drill, end mill, graver and micro-drill PCB with diameter less than 0.8 mm.

|

|

|

|

|

|

||||||

|

JZ12U

|

Be suitable for semi-finishing and finishing process of stainless steel, mold steel and normal titanium alloy, etc. Recommend for making all types of high speed end mills, reamers and gravers.

|

|

|

|

|

|

||||||

|

JZ12U-T

|

Be suitable for finishing process of stainless steel, mold steel and normal titanium alloy etc. Recommend for making all types of high speed end mills, reamers and gravers.

|

|

|

|

|

|

||||||

|

JZ10S

|

Suitable for cutting alloy steel, stainless steel, non-ferrous metal, high temperature allooy and so on.

|

|

|

|

|

|

||||||

|

JZ10F

|

For general use of milling and drilling, suitable for cutting alloy steel, stainless steel, non-ferrous metal, high temperature alloy and so on.

|

|

|

|

|

|

||||||

|

JZ10C

|

Suitable for machining non-ferrous metal, aluminum with a high silicon content and graphite (with diamond coating).

|

|

|

|

|

|

||||||

Application

Our carbide rods can make precision tools like drills, end mills, milling cutters, and reamers in a variety of diameters and lengths, with coolant holes or without.

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

|

Q1: What's your company's production facilities and capacity?

|

|

A1: Our company currently has 63 self-presses (50 sets of 3T, 10 sets of 6T, 2 sets of 25T and 1 set of 50T), 9 sets of hydraulic presses 12 sets of vacuum sintering furnaces and 3 sets of over-pressure sintering furnaces, and the capacity can reach 40 tons a month.

|

|

Q2: What processing equipment do you have?

|

|

A2: 4 sets of Surface Grinder, 20 sets of Tool Grinder, 2 sets of Polishing Machine, 3 sets of Centerless Grinder, 1 set of Round Table Grinder, 2 sets of Wire Cutting.

|

|

Q3: What's the payment terms?

|

|

A3: 100% in advance or 30% in advance, balance before shipping.

|

|

Q4: What testing equipment do you have?

|

|

A4:Cobalt magnetic analyzer, WC particle size analyzer, CT detector, Metallographic image analyzer, Hardness machine, tensile strength testing machine, Density meter, Ultrasonic flaw detector ,3D coordinate instrument, Image measuring instrument, Chemical analyzer set etc

|

|

Q5: What are the qualifications of your company?

|

|

A5: GB/T24001-2016/ISO14001:2015; GB/T 19001-2016 idt ISO 9001:2015

|

|

Q6: What's the price of non-standard carbide?

|

|

A6: Blank price + processing cost, quoted by piece. Difficulty factor and machining accuracy will affect the price.

|

|

Q7: What's the delivery time for non-standard carbide?

|

|

A7: Normally delivery time is 7-10 days, processing according to your drawings to do additional processing procedures and process schedule, in general 5-10 days, the specific to wait for your order confirmation according to the workshop production and processing capacity to determine the delivery date. Non-standard products are scrapped, we do our best to deliver according to the contract date, special circumstances reported to you in advance.

Packaging is divided into wooden boxes and cartons two kinds of outer packaging, with foam, bubble film and other fillers, 100% full checking before delivery |

|

Q8: I only have samples, can you provide formal drawings?

|

|

A8: We could provide formal drawings based your sample as long as you also offer me the tolerance for each size.

|

Hot Searches