- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Beacon

-

Model Number:

-

HP-A

-

Driver power:

-

55KW-level 4

-

Motor:

-

5.5KW

-

System limit pressure:

-

30MPa

-

System maximum pressure:

-

30MPa

-

Maximum displacement:

-

300-400L/min

-

speed:

-

level 4 motor 0--2000r/min

-

Working medium:

-

isovg46 hydraulic oil

-

Normal cleaning requirements:

-

GB/T14039 19/16 (NAS10)

-

Weight:

-

25000KG

Quick Details

-

Warranty:

-

1 year

-

Power:

-

Electronic

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Beacon

-

Model Number:

-

HP-A

-

Driver power:

-

55KW-level 4

-

Motor:

-

5.5KW

-

System limit pressure:

-

30MPa

-

System maximum pressure:

-

30MPa

-

Maximum displacement:

-

300-400L/min

-

speed:

-

level 4 motor 0--2000r/min

-

Working medium:

-

isovg46 hydraulic oil

-

Normal cleaning requirements:

-

GB/T14039 19/16 (NAS10)

-

Weight:

-

25000KG

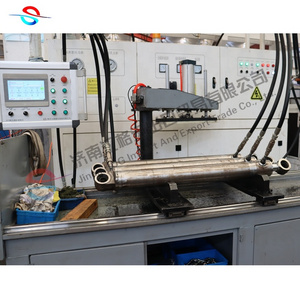

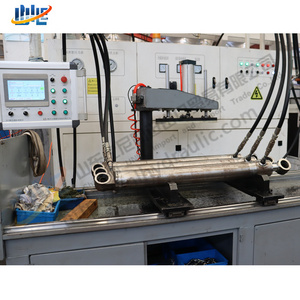

hydraulic cylinder test bench hydraulic test bench for sale hydraulic pump test bench design HP-A

Product Overview

The 55KW hydraulic pump valve cylinder comprehensive test table is a special equipment for hydraulic pumps, hydraulic motors,

hydraulic valves, and hydraulic oil cylinders. Its structure, performance, use and maintenance knowledge refer to this instruction

manual.

hydraulic valves, and hydraulic oil cylinders. Its structure, performance, use and maintenance knowledge refer to this instruction

manual.

55KW hydraulic pump valve cylinder comprehensive test platform

Function:

1. Uses: 55KW hydraulic pump pump valve cylinder comprehensive test platform

1. It is a comprehensive test table for detecting hydraulic pumps/motors/valves // oil cylinders. It is a special equipment for

hydraulic pumps, hydraulic motors, valves, and cylinders. It has the characteristics of compact structure, reliable quality,

reasonable design, easy operation and maintenance, and refer to the various technical requirements in GB3766-88 "Smart Technical

Conditions for Hydraulic Systems".

2. The hydraulic system of this test table adopts a closed fuel tank structure to allow work in a dusty environment. However, pay

attention to the dust on the hydraulic equipment when using it to ensure that the hydraulic system has good heat dissipation and

the cleaning of oil Essence

Second, structural characteristics

1. This device uses an electric motor as the driver system of the entire test table. The testing table is divided into three

parts: the motor drive table, the main oil box valve console, the valve and the tank detection table. The installation structure

has the advantages of large volume, compact structure, and convenient installation.

2. The integrated oil circuit block design makes the system has less leakage, and the structure is compact, disassembled and

convenient.

3. The output oil circuit is arranged neatly, clear, and easy to operate.

4. Test the pressure -regulating operation is simple and clear.

The details photos

1. Main technical indicators:

Weight 3-4t (theoretical weight)

Dimensions: Test Power Channel: 2000X2000X1800mm

Driver power: 55KW-level 4

Auxiliary motor 5.5kW, low -voltage oil supply pump 10 pump pump 10 plunger pumps

The highest oil supply pressure is up to 20MPa

System maximum pressure: 30MPa

System limit pressure; 30MPa

Maximum displacement: 300-400L/min

2. The functional configuration and parameters of the test bench:

2.1 Driver method: motor driver

2.2 speed: level 4 motor 0--2000r/min; (frequency conversion)

2.3 Loading method: manual dual road loading pressure

2.4 Oil supply method: forced oil supply and self -absorbing oil supply.

2.5 Display method: Digital table and PLC touch screen display

3.2.6 Operation method: manual operation.

4. Working medium: isovg46 hydraulic oil;

5. The volume of the fuel tank: 1000L actual refueling 800L;

6. Normal cleaning requirements: GB/T14039 19/16 (NAS10)

2. The functional configuration and parameters of the test bench:

2.1 Driver method: motor driver

2.2 speed: level 4 motor 0--2000r/min; (frequency conversion)

2.3 Loading method: manual dual road loading pressure

2.4 Oil supply method: forced oil supply and self -absorbing oil supply.

2.5 Display method: Digital table and PLC touch screen display

3.2.6 Operation method: manual operation.

4. Working medium: isovg46 hydraulic oil;

5. The volume of the fuel tank: 1000L actual refueling 800L;

6. Normal cleaning requirements: GB/T14039 19/16 (NAS10)

Fourth, installation instructions

:

1. This hydraulic system should carefully check whether each part of the hydraulic system meets the contract supply scope and

whether the design requirements are met, and whether there is damage, or whether the hydraulic system meets the contract.

2. In the installation of each part of this hydraulic system, it should be ensured that all the exposed oil port blocks or bandage

should be ensured. Before the equipment installation is installed, it must not fall off to avoid pollution to the hydraulic

system.

3. After the hydraulic system is transported to the installation position, it should be fixed firmly on the basis of the design

drawings, so as not to loosen, so as not to affect its use performance.

4. After each part of the hydraulic system is in place, please pipe according to the hydraulic operation chart.

5. When installing the connection, be careful not to miss and damage the sealing part.

6. After the hydraulic system is installed, please connect the hydraulic system wiring diagram.

Five, debug instructions

1. After the hydraulic system is installed, first check whether the installation of each part of the hydraulic system is correct,

the pipeline connection is correct, and whether the electrical wiring is correct, otherwise it should be processed in time.

2. The cover of the empty filter is covered, and the filter vehicle with the filtering accuracy is not less than 20um to add the

hydraulic oil to the liquid level to the upper limit of the hydraulic level through an empty filter, and then restore the empty

filter.

3. All the adjustment knobs on the table on the table to zero.

4. Click the motor, if you cannot start, you should re -adjust the line. Pay attention to the direction!

6. Operation control instructions

1. Before use, check whether the adjustment screws of each component and auxiliary parts in the system should be in the correct

position, whether the oil is within the indication range of the liquid level meter, and the pipeline joints, fastening screws,

etc. Can be put into operation.

2. Before the motor starts and stops, loading, fuel supply, pilot, and speed adjustment left to zero, so that the motor starts or

stops in the air load state.

3. In the process of using oil absorption and oil returning oil filter, if it is blocked, please clean or replace it in time.

4. The lock -up overflow valve must not be adjusted at will.

5. The fuel level cannot be lower than the liquid level. When the oil is found, it should be refueling in time.

6. When the system fails, it should be stopped in time.

7. During the use of this hydraulic system, the oil replacement is replaced, component and auxiliary replacement conditions, and

the fault treatment situation is recorded in detail to facilitate future maintenance, maintenance and fault analysis.

Seven, maintenance

1. This hydraulic system is debugged. In the future, the hydraulic oil is replaced every other year. After each oil change, the

oil tank must be cleaned to replace the oil filter element to ensure the normal operation of the hydraulic system.

2. During the use process, check the oil filter at any time and clean or replace the filter element in time.

3. This hydraulic system should usually always be prone to damage parts, components, and auxiliary spare parts in order to deal

with faults in a timely manner.

8. Common faults and treatment

Fault solve

3.The jitter pressure is unstable stuck to block, and clean up or replace

Nine, accessories and easy loss parts

In the system, the valve is loaded, the unidirectional valve and the filter element are easy to be damaged.

10. 55KW hydraulic pump pump valve cylinder comprehensive test platform operating procedures

55KW hydraulic pump valve cylinder comprehensive testing table operating procedure

closed pump (motor) test operation regulations:

1. Preparation stage:

1. Open the control switch power supply to send power;

2. Open the instrument switch,

3. Intellectual switch, (open) (closed) to the left, observe the overflow valve, can be used normally. On the contrary, twist the

right to the right, turn on the impact test at this time

4. Select the left rotor and right rotation switch according to the rotation of the test pump;

5. All loading, fuel supply, and pilot knobs are left to zero, and the speed adjustment knob is returned;

6. Pump inhalation connecting the oil -absorbing port intercept valve opens

7. The ball valve connecting the tube is opened, and those who are not connected are closed

8. Connect the oil port of the subject pump (motor) housing oil port, pump (motor) port A and B connections connect to the closed

type A and B ports on the corresponding pump countertop;

Test pump

Pioneer oil leakage oil

Oil -absorbing port closed high -pressure A closed high -pressure B open high -pressure B

(Oil supply) (oil supply)

Open high -voltage A

O leaked oil port

O pilot oil A port O pilot oil B port

O closed high -pressure A port (oil supply port) O closed high -pressure port B (oil supply port)

O open high -voltage A port O open high -voltage B port

O oil absorption

Note: If the oil supply is required, the pumping oil port is connected to a closed high -pressure A or B port. The low -pressure

oil supply motor needs to be started, and the low -pressure oil supply pressure control knob needs to be adjusted to adjust the

oil supply pressure to 1.5 ~ 2 mega na;

2. Test operations: (forced oil supply, low pressure oil supply)

PRODUCT SPECIFICATIONS

|

Test operation procedures for hydraulic valve:

|

|

1. Preparation stage: (forced oil supply)

|

|

1. Open the control switch power supply to send power;

|

|

2. Open the instrument switch,

|

|

3. The above shock switch is hit to the usual bright state, and the impact test in the opposite direction

|

|

4. Select the left -handed and right rotation switch according to the steering of the pump;

|

|

5. All loading and oil -supply knobs are left -handed and zero, and the speed adjustment knob is zero;

|

|

6. Open the ball valve connecting the tube

|

|

7. Open A or B, C, and D of the pumping countertop connection on the high -voltage port on the valve high -voltage port;

|

Certifications

Customer Feedback

Customer Photos

Our Company

Contact Us

Hot Searches