- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Power:

-

132kw

-

Dimension(L*W*H):

-

12*2.1*2.4m

-

Weight (KG):

-

2600

-

Product name:

-

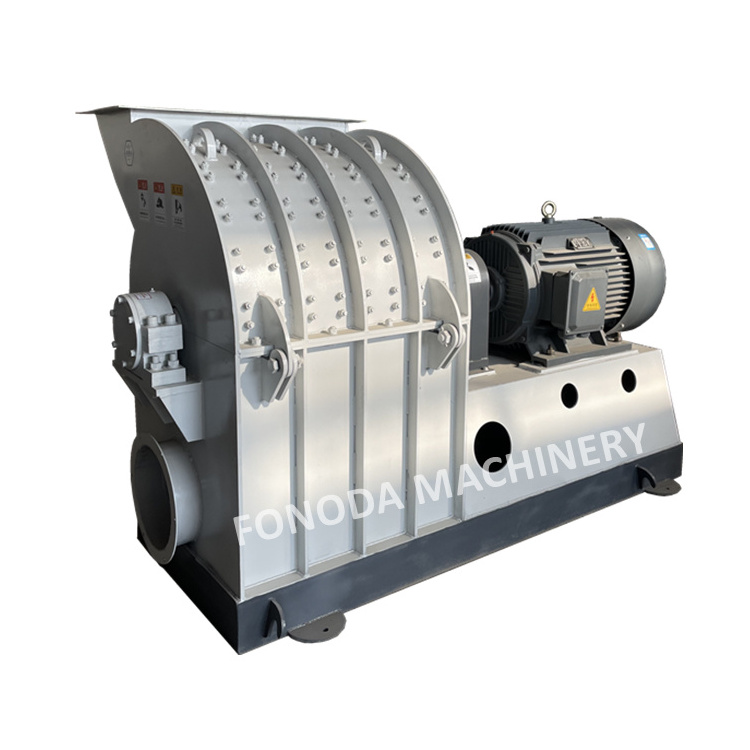

Sawdust Crusher Hammer mill

-

Application:

-

Biomass/ Wood Crushing

-

Final product:

-

3- 10mm optional

-

Advantage:

-

Large capacity, large sized input

-

Type:

-

Rotary hammer blades

-

Suitable material:

-

Mass biomass materials

-

Hammers Qty:

-

96/ 120 pcs

-

Capacity:

-

5 -7 ton/h

-

Engine:

-

Electric

-

Wearing parts:

-

Hammer| Sieve

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fonoda Machinery

-

Marketing Type:

-

New Product 2023

-

Voltage:

-

380v

-

Power:

-

132kw

-

Dimension(L*W*H):

-

12*2.1*2.4m

-

Weight (KG):

-

2600

-

Product name:

-

Sawdust Crusher Hammer mill

-

Application:

-

Biomass/ Wood Crushing

-

Final product:

-

3- 10mm optional

-

Advantage:

-

Large capacity, large sized input

-

Type:

-

Rotary hammer blades

-

Suitable material:

-

Mass biomass materials

-

Hammers Qty:

-

96/ 120 pcs

-

Capacity:

-

5 -7 ton/h

-

Engine:

-

Electric

-

Wearing parts:

-

Hammer| Sieve

Product Description

Wood Hammer Mill Crusher

The multifunctional hammer mill crusher is widely used in crushing various biomass wood waste and stalk material. The motor and the hammers are directly connected by the coupling. There is no dead angle during the crushing so the finished product is very fine. The corners of the hammers are welded with high hardness material like carbon tungsten alloy. The welding layer thickness is around 3mm. The lifetime is 7- 8 times by normal 65Mn overall quenching hammer. The rotor has made the balance test and can work backward. It's the best choice to prepare milled material for pellet machine.

Structures

This hammer mill has rotors, and the rotors are mounted with hammers. With the rotating of the rotor, the hammers running at a high speed. When the raw material passed the feeder and come into the working body, they will touch the hammers, and get crushed. When the material become small enough, they will go through the screen’s wholes by the help of fan. After crushing, the final size will depend on the screen size, for example, 3-5 mm, which is enough for pellets making or briquettes making.

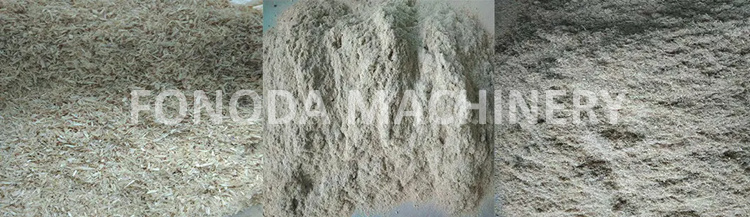

Finished sawdust/powder ↑:

1-16mm or customizable

Product Details :

Sieve Mesh

The bottom diameter of screen is 6mm-12mm, thickness is greater than 4mm

Hammer

The corners of the hammers are welded with high hardness material like carbon tungsten alloy. The welding layer thickness is around 3mm. The lifetime is 7- 8 times by normal 65Mn overall quenching hammer.

Rotor Group

The motor and the hammers are directly connected by the coupling. There is no dead angle during the crushing so the finished product is very fine. The rotor has made the balance test and can work backward.

The bottom diameter of screen is 6mm-12mm, thickness is greater than 4mm

Hammer

The corners of the hammers are welded with high hardness material like carbon tungsten alloy. The welding layer thickness is around 3mm. The lifetime is 7- 8 times by normal 65Mn overall quenching hammer.

Rotor Group

The motor and the hammers are directly connected by the coupling. There is no dead angle during the crushing so the finished product is very fine. The rotor has made the balance test and can work backward.

Specification

Sawdust Making Machine Powder Grinding Machine

Wood hammer mill is endowed with many advantages compared to other kind of crushers such as large reduction rate, high production capacity, even crushed effects, low energy consumption and simple structure, etc. It can be used to crush hard, soft and weakly corrosive materials. After crushing, raw materials are unifon and with proper moisture content to meet further processing

|

No

|

Model

|

Capacity( output)

|

Motor

|

|

1

|

800

|

3 ton/h

|

90kw +22kw( fan)+ 3kw( air-lock)

|

|

2

|

1000

|

5 ton/h

|

110kw +30kw( fan)+ 3kw( air-lock)

|

|

3

|

1200

|

7 ton/h

|

132kw +30kw( fan)+ 3kw( air-lock)

|

Application:

The multifunctional hammer mill is widely used in crushing various biomass wood waste and straw material. It's the best choice to prepare milled material for pellet machine.

Applicable Raw Material:

All kinds of biological stalks, (such as corn stalk, wheat straw, cotton stalk), rice straw, rice shell, peanut shell, corn cob, Small pieces of wood, sawdust, branches, weeds ,leaves, bamboo products and other waste.

Product Advantage:

1, Multifunction

This machine has two series which are single-shift type and double-shift type. The machine's capacity is big and the efficiency is high. It could be operated and maintained easily.

2, Good-quality End Products

The machine is used for crushing dry and oil-free feeds and the end products are very fine.

3, Durable in Use

The corners of the hammer are bead welded with high hardness material like carbon tungsten alloy. The welding layer thickness is 3mm. The lifetime is 7- 8 times by normal 65Mn overall quenching hammer.

4, Pollution-free and High Efficiency

The inner cooling structure of the crusher could avoid the high-temperature damage which comes from the rubbing, and increase the life of the machine. The machine is equipped with dust collector which avoids the powdery pollution. All in all, this machine is low temperature with small noise and high efficiency.

This machine has two series which are single-shift type and double-shift type. The machine's capacity is big and the efficiency is high. It could be operated and maintained easily.

2, Good-quality End Products

The machine is used for crushing dry and oil-free feeds and the end products are very fine.

3, Durable in Use

The corners of the hammer are bead welded with high hardness material like carbon tungsten alloy. The welding layer thickness is 3mm. The lifetime is 7- 8 times by normal 65Mn overall quenching hammer.

4, Pollution-free and High Efficiency

The inner cooling structure of the crusher could avoid the high-temperature damage which comes from the rubbing, and increase the life of the machine. The machine is equipped with dust collector which avoids the powdery pollution. All in all, this machine is low temperature with small noise and high efficiency.

Packing & Delivery

Use wooden case or whole container based on the model size.

Ship by sea to your seaport.

Hot Searches