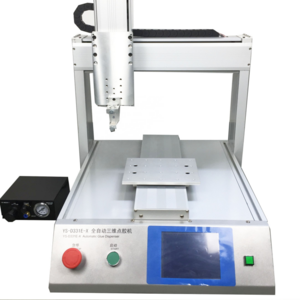

* Features can include;

* Industry 4.0 data acquisition features;

* Automatic fluid viscosity control;

* Production line integration;

* UV curing process;

* Variable rate timing;

* Fume extraction;

* Temperature control

* Automatic fluid viscosity control;

* Production line integration;

* UV curing process;

* Variable rate timing;

* Fume extraction;

* Temperature control