- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v/380v/415v

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

OUGUAN

-

Dimension(L*W*H):

-

10000*2200*2300mm

-

Weight:

-

5500 KG

-

Product name:

-

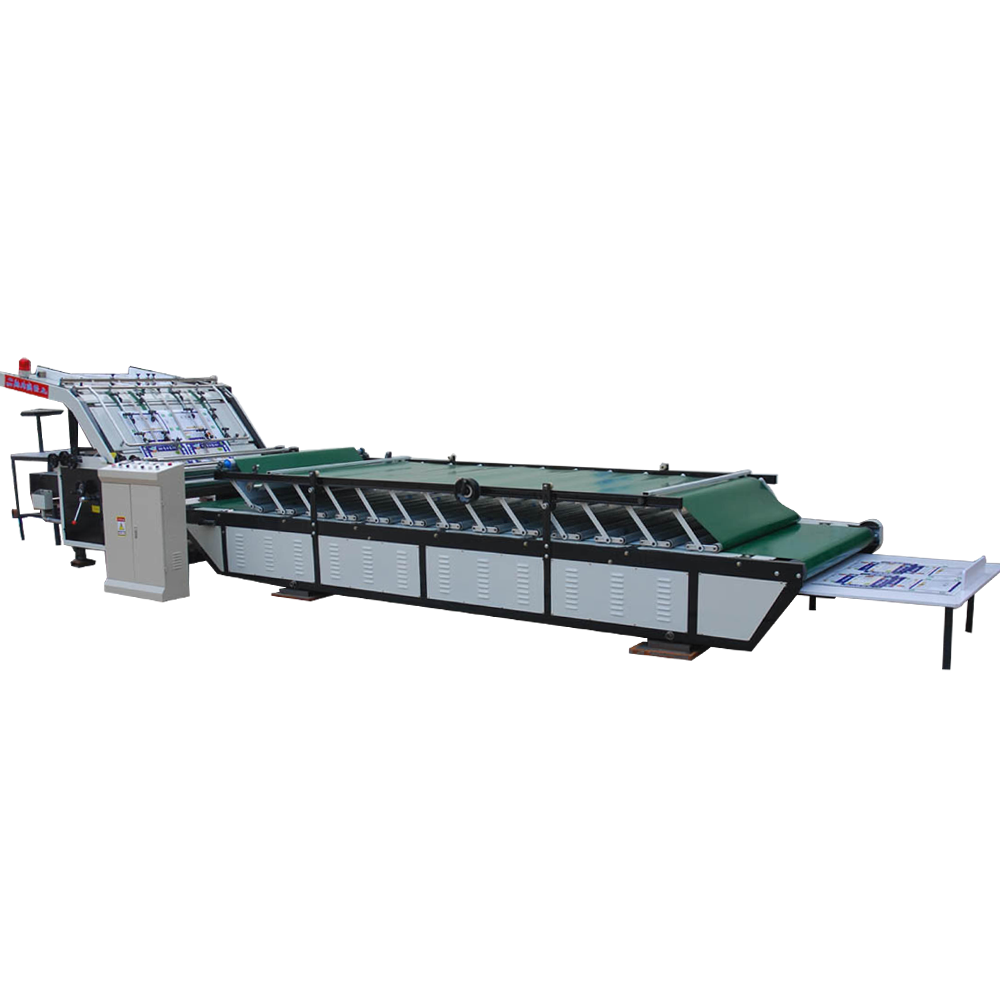

Flute Laminating Machine

-

After-sales Service Provided:

-

Online support

-

Marketing Type:

-

Hot Product 2023

-

Max thickness:

-

10mm

-

Speed:

-

0-90m/min

-

Function:

-

Paper Cardboard Box Gluing Machine

-

Color:

-

Customers' Demand

-

Material:

-

Stainless Steel

-

Package:

-

Film And Wooden box

-

Machine type:

-

Automatic Control

Quick Details

-

Packaging Type:

-

Film

-

Packaging Material:

-

Plastic, Wood

-

Driven Type:

-

Electric

-

Voltage:

-

220v/380v/415v

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

OUGUAN

-

Dimension(L*W*H):

-

10000*2200*2300mm

-

Weight:

-

5500 KG

-

Product name:

-

Flute Laminating Machine

-

After-sales Service Provided:

-

Online support

-

Marketing Type:

-

Hot Product 2023

-

Max thickness:

-

10mm

-

Speed:

-

0-90m/min

-

Function:

-

Paper Cardboard Box Gluing Machine

-

Color:

-

Customers' Demand

-

Material:

-

Stainless Steel

-

Package:

-

Film And Wooden box

-

Machine type:

-

Automatic Control

Product Description

1.The top paper can be stacked up to 1.5 meters at a time, and the paper pile rises automatically during the paper feeding process, making paper feeding easier and more efficient.

2.

The bottom paper adopts aspirating automatic feeding, which can automatically track continuously according to the speed of manual feeding paper.

3.

The new concept is pre-defined, the positioning accuracy is high, the bottom paper is never ahead, and the front paper is adjustable.

4.

The whole machine adopts touch screen/PLC control system, the circuit system runs stably, and can automatically display fault alarm.

5.

Fully automatic glue replenishment system, which can automatically replenish the lost glue amount during the laminating process, and cooperate with glue recycling to avoid glue loss and waste.

6.

The scientific design of the measuring roller line speed ensures the uniform amount of glue and avoids the glue silicone at high speed.

7.

It is convenient and fast to adjust the pressure of each pressing roller by adopting the unidirectional adjustment of the worm wheel rod.

8.

The cleaning water source adopts a separate water tank to control the water circulation mode, and simultaneously cleans the rubberizing roller, the rubber roller, and the recovery tank.

9.Suitable for 175g-500g color printing paper and A/B/C/D/E/F corrugated paper, 175g-500g color printing paper and gray cardboard

|

Model

|

BZJ-1300Q

|

BZJ-1450Q

|

BZJ-1600Q

|

|

Max size(W×L)

|

1300×1100mm

|

1450×1100mm

|

1600×1100mm

|

|

Min size(W×L)

|

350×350mm

|

350×350mm

|

350×350mm

|

|

Total power

|

8.5kw

|

9.5kw

|

9.5kw

|

|

Speed

|

0-90m/min

|

0-90m/min

|

0-90m/min

|

|

Weight

|

5500kg

|

6500kg

|

7500kg

|

|

Overall size(L*W*H)

|

10000×2200×2300mm

|

10000×2350×2300mm

|

10000×2500×2300mm

|

Other Products

Customer Feedback

Hot Searches

![[JT-YB1650HS] Flute Litho Laminator Machine Corrugated Sheet Flute Laminating Machine CE Automatic](https://cdn.bestsuppliers.com/seo_products_img/jeta/4dc22e7ad30e33c0b8e7471814e96e07.jpg!/rotate/180/sq/300)