- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa

-

Voltage:

-

220V OR 380V

-

Dimension(L*W*H):

-

1350*1460*1800mm

-

Weight (KG):

-

6000000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

aac block manufacturing machine

-

Raw material:

-

Fly Ash or sand

-

Weight/M3:

-

500kgs/m3-700kgs/m3

-

Power:

-

170KW

-

other name:

-

bricks making machine lowest price

Quick Details

-

Type:

-

Autoclaved aerated concrete block (AAC), light weight block, AAC Ytong block production line, Hebel Bricks AAC Blocks Making Produce Factory

-

Brick Raw Material:

-

fly ash or sand

-

Production Capacity (Pieces/8 hours):

-

4000-60000 Pieces/day, customized

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa

-

Voltage:

-

220V OR 380V

-

Dimension(L*W*H):

-

1350*1460*1800mm

-

Weight (KG):

-

6000000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

aac block manufacturing machine

-

Raw material:

-

Fly Ash or sand

-

Weight/M3:

-

500kgs/m3-700kgs/m3

-

Power:

-

170KW

-

other name:

-

bricks making machine lowest price

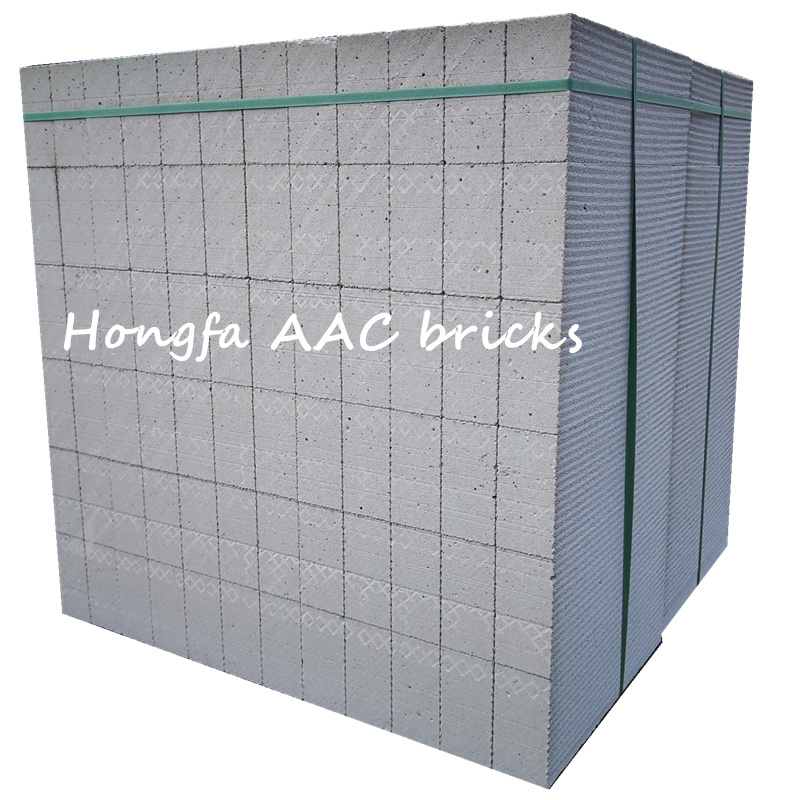

AAC block manufacturing machine plant cost bricks making machine lowest price

Autoclaved aerated concrete (shorted as AAC) is a kind of lightweight precast concrete, it was invented in the mid-1920s and has developed for around 100 years. Since 1980, the production of AAC Blocks continues to increase globally and it is increasingly used by developers, architects, builders around the world, especially for prefabricated building, this is in line with the development trend of the construction industry.

manufactures autoclaved aerated concrete (AAC) or aerated lightweight concrete (ALC) block and panel, it is a composite of cement, lime, and silica sand. Besides, ALC panel uses bidirectional welded steel mesh (reinforcing bar) , which has been treated with a superior rust preventive liquid and cured with high-temperature, high-pressure steam. A porous silicate board is manufactured for high performance of anti-permeability and sound insulation. It can be divided into external wall panels, partition panels (internal wall panels), floor panels and roof slabs according to the purpose.

AAC blocks and ALC panels are widely used in various projects,such as commercial, factory, and residential buildings etc. The product has the characteristics of convenient installation, wide application range, and high construction accuracy; meanwhile, it can greatly improve the usage performance of the building, and reduce the cost of construction.

Brief introduction

Areated concrete brick (light brick ) is the light and porous buidling material. It has light weight keeping temperature cant burn and other advantages.it can be made into many kinds of bricks(for example:600×200×100,80×80×180,240×115×53,600×200×125),they could be used industry building and common building.they are more and more popular in the world.in the future,they will replace the Clay brick completely.

Advantages

light weight

Areated concrete density is usually 400-700kg/m3,(according the market in produce ),same as 1/3 of clay brick and 1/5 common concrete.So use the Light brick can reduce the weight of the build more,and also reduce the beam of roof and pillar press best.then you can see,it can save the material and cost,it also fighting shaking.

keeping temperature

aerated concrete panel has many porous,the delivery hearting coefficient is 0.9-0.22W/(mk),the same as 1/4 or 1/5 of clay brick,so it is best materials now in the world. Also many kinds raw material,have lowest wasteMain Material:coal ash sand waste mine material coal stone,stone dust and other silicon materials.

General specification

| Dry density level | B03 | B04 | B05 | B06 | B07 | B08 | |

| Dry density kg/m³ | Premium product(A)Less than or equal to | 300 | 400 | 500 | 600 | 700 | 800 |

| Qualified product(B) Less than or equal to | 325 | 425 | 525 | 625 | 725 | 825 | |

| table 2 | |||||||

| Dry density level | B03 | B04 | B05 | B06 | B07 | B08 | |

| Intensity level | Premium product(A) | A1.0 | A2.0 | A3.5 | A5.0 | A7.5 | A10.0 |

| Qualified product(B) | A2.5 | A3.5 | A5.0 | A7.5 | |||

| According to product strength and bulk density (weight per cubic meter), it is divided into different grades. Commonly used are: strength A3.5, bulk density B06. The higher the strength and the lighter the bulk density, the higher the price. | |||||||

|

As a load-bearing wall: block products with a strength grade of not less than A5.0 should be used

As a filling wall: when used for external walls, block products with a strength class of not less than A3.5 should be used; when used for interior walls, block products with a strength class of not less than A2.5 should be used. |

|||||||

| Common specifications of block | ||

| Name | Product grade | specification:length* width* high mm |

| AAC High-precision block | B04-A2.5 | 600*250*50 |

| 600*250*75 | ||

| 600*250*100 | ||

| B05-A3.5 | 600*250*150 | |

| 600*250*200 | ||

| B06-A5.0 | 600*250*250 | |

| 600*250*300 | ||

| AAC Ordinary block | B04-A2.0 | 600*250*100 |

| 600*250*150 | ||

| B05-A3.5 | 600*250*200 | |

| B06-A5.0 | 600*250*250 | |

| 600*250*300 | ||

ALC block (Autoclaved Lightweight Concrete Block) is also called AAC Block (Autoclaved Aerated Concrete Block) which is steel mesh reinforced, lightweight and loadbearing.

Autoclaved Aerated Concrete Block are widely used as external wall panel (exterior wall panel), internal wall panel (interior wall panel), partition wall panel, flooring, roofing, fence, cladding, curtain wall and facade etc.

Autoclaved Aerated Concrete Block are widely used in different kinds of buildings, such as public facilities, industrial constructions, steel structure building, warehouse, workshop, stores, hospitals, hotels, apartments, villas, schools, supermarkets etc.

Autoclaved Aerated Concrete Block can replace traditional precast concrete and clay bricks very well. Also the panels can easily cut, drilled, screwed when installing with fast speed due lightweight and precast.

Hebel Bricks AAC Blocks Making Produce Factory Machinery From Manufacturer

aerated concrete panel programme

1, Technological Standard

The technological standard of this project is superior products according to the Chinese national standards. The equipments are made according to Chinese standard and criterion

This project provides the mature tilting technology in China.

2, Capacity

The product is AAC blocks with the capacity of 30,000m3- 3 00,000m3 /year

3. Product specification

The products reach the block requirements of grade 04~07 of GB11968-2006

Main Material

coal ash sand waste mine material coal stonestone dust and other silicon materials.

1. Product weight is according to 600kg/m3 to control.

2 .annual capacity 200,000M3.

3. set raw material proportion: cement 6.5%, raw lime 23%, flyash 68%, gypsum 3%, aluminum paste powder 350g/M3.

4. water and material rate 0.631

5. one mould product 2.88M3

6. Casting slurry cycle time 5-6 minutes, cut cycle time 5 minutes.

7.casting slurry temperature 38-42 degree

8 .body quiet stop. Time is 1.5-2.5housr, temperature 50-90 degree, after quiet stop body strength is 0.15-0.18Mpa

9 .Steam curing cycle time, come in and out autoclave about 0.5hour, steam curing cycle time about is 6 hours/1.6Mpa, total 6.5 hours

1.

Material dealing process

Put the fly ash or sand into the ball mill to mill via the conveyor belt, after milling, put the slurry into the slurry storage tank by slurry pump.

2. Batching, mixing and pouring process

The lime, cement will convey by conveyor to the dry powder measure scale to scale separately. The slurry convey by slurry pump then to the automatic scale;the power and slurry put into the mixer,pouring into the mould.

3. Curing process

After slurry pouring into the mould, put the mould box into the curing room with 50~ 70℃. After 2-3 hours curing,the blocks become solid

4. Cutting process

Using reversal crane carry the mould and block to demould on cutting cart. The cutting cart will take the block to level cutting machine,vertical cutting ,two sides cutting,and remove the top waste material.

5. Autoclaved

Finished cutting using semi-product crane carry to the front of autoclave grouped,hoisting machine or dragger will drag steam trolley into autoclave to steam,it need 10-12 hours.

6. Finished block dealing

Finished product out of autoclave,with separting machine to separate layer by layer.

7. Package

Using finished block carry hanger clamp the finished product to package line on wooden pallets,after package, then by forklift transport the finished products to piled yard according to specifications to stack.

Packing: Naked packing or stretch film packing or according to customers' requirements

Delivery time: Within 30 days after receipt of deposit and moulds confirmation from buyer

1.Guarantee for one year and after sale service for whole life.To offer free design,free technology support and free machine maintenance trainning.

2.We will provide you with a set of spare parts for free!