- Product Details

- {{item.text}}

Quick Details

-

Coating:

-

PVDF coating

-

Thickness:

-

0.1-0.50mm

-

Core material:

-

Excellent Non-toxic PE

-

Panel thickness:

-

2/3/4/5/6mm

-

Panel Width(mm):

-

1220mm,1250mm,max 1550mm

-

Panel Length(mm):

-

2440mm,3050mm,max 6000mm

-

Certification:

-

ISO9001/SONCAP

-

Application:

-

building facade material

-

Product name:

-

alu dibond aluminum composit panel clad system 4ft x 8ft

Quick Details

-

Size:

-

1220x2440mm

-

Place of Origin:

-

Shandong, China

-

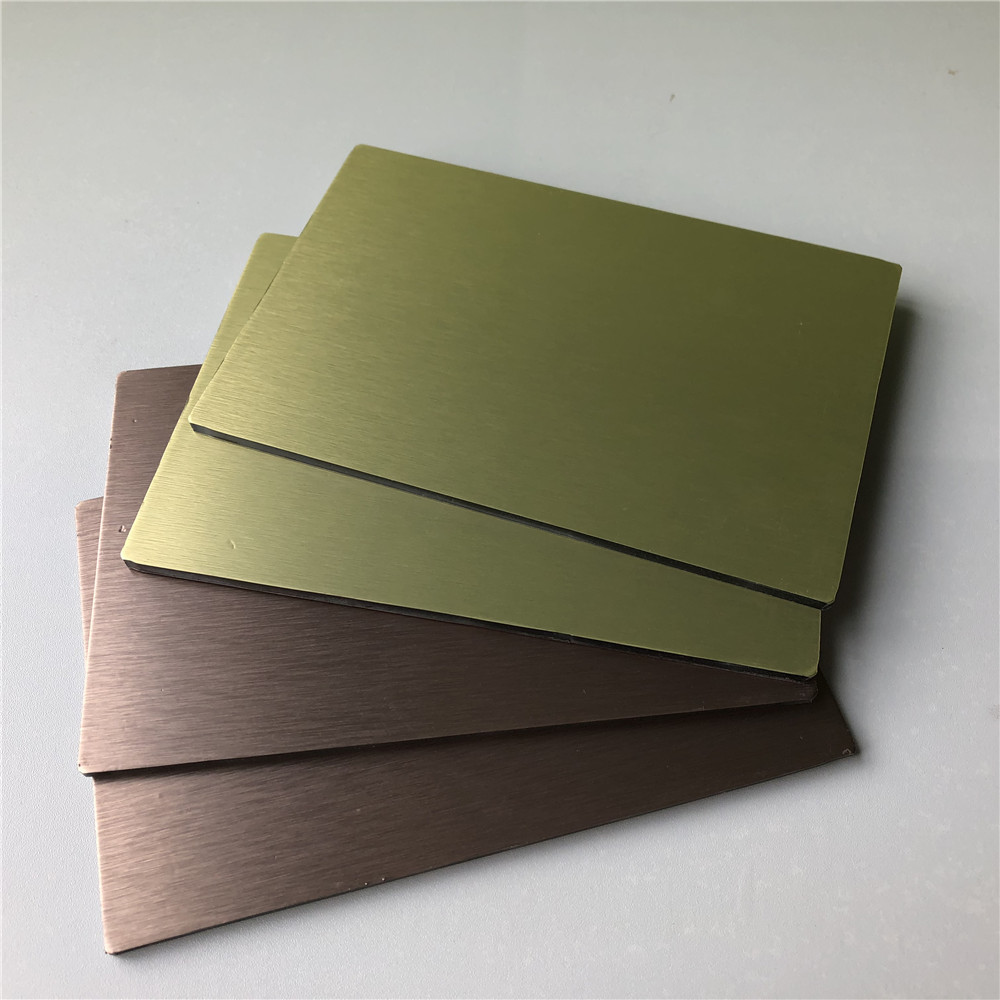

Color:

-

multi

-

Coating:

-

PVDF coating

-

Thickness:

-

0.1-0.50mm

-

Core material:

-

Excellent Non-toxic PE

-

Panel thickness:

-

2/3/4/5/6mm

-

Panel Width(mm):

-

1220mm,1250mm,max 1550mm

-

Panel Length(mm):

-

2440mm,3050mm,max 6000mm

-

Certification:

-

ISO9001/SONCAP

-

Application:

-

building facade material

-

Product name:

-

alu dibond aluminum composit panel clad system 4ft x 8ft

Building facade material alu dibond aluminum composit panel clad system 4ft x 8ft

| Specifications | |

| Product name | Building facade material alu dibond aluminum composit panel clad system 4ft x 8ft |

| Panel Width(mm) | 1220mm,1250mm,max 1550mm |

| Panel Length(mm) | 2440mm,max 6000(no limited as per loading container) |

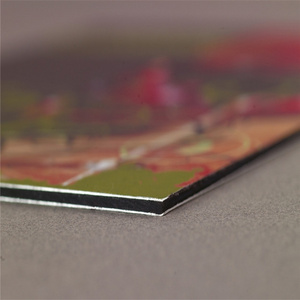

| Panel thickness(mm) | 2mm/3mm/4mm/5mm/6mm (Standard 3mm/4mm) |

| Aluminum Alloy | AA1100,AA3003,AA5005(Other grade as per requirement) |

| Aluminum coil thickness | 0.21mm-0.5mm |

| Coating | PVDF coating |

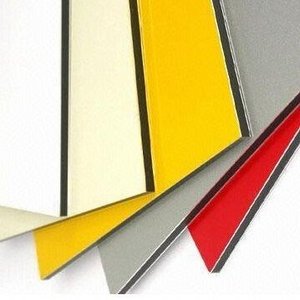

| Color | RAL, PANTONE,GEESHINE color chart or customers' requirement |

| PE core material | non-toxic low density polyethylene |

| Back coating | primer coating |

| Warranty | 15-20 years for outdoor wall cladding usage |

| Base material | high strength aluminum alloy sheet |

| Delivery time | 10-15 working days after the deposit |

| Packing | FCL, In bulk,LCL,In wooden pallet package or according to customers' requirement |

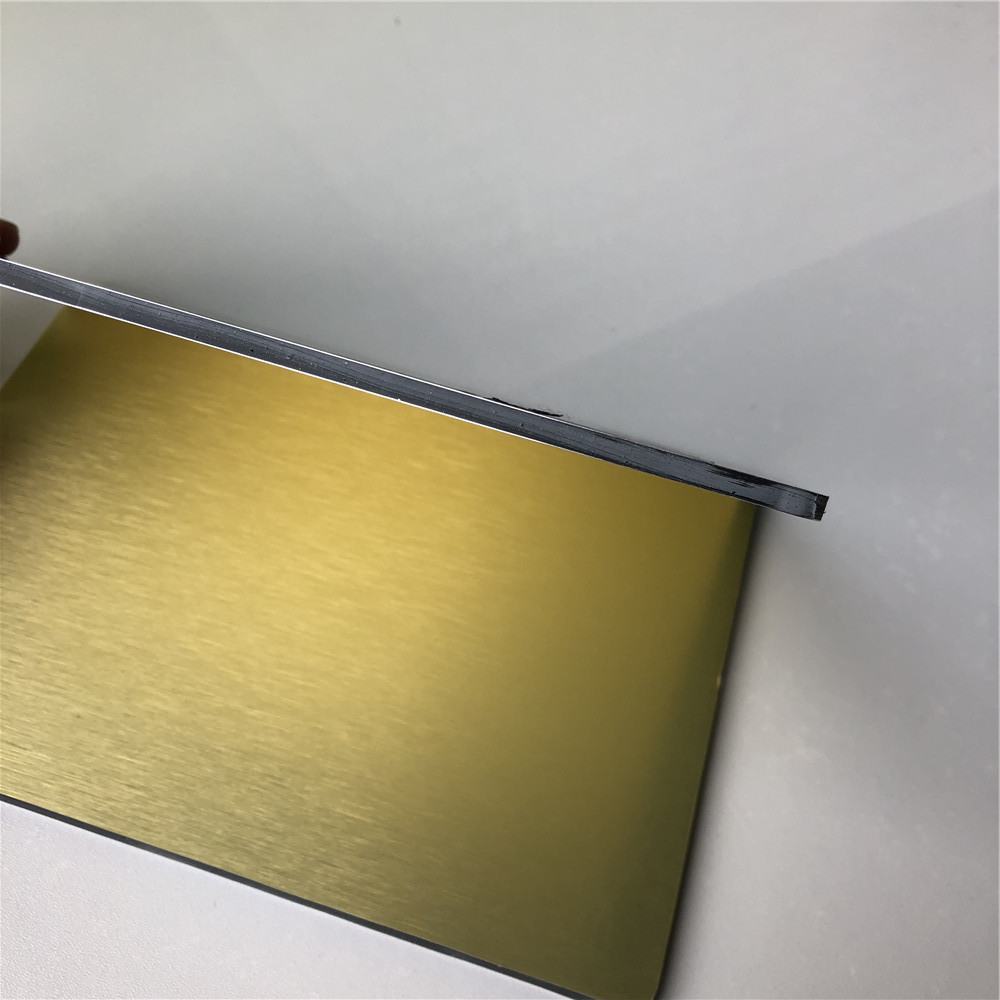

Consist of aluminum composite panel

Surface

: aluminum alloy(AA1100 series,AA3003 series) coated with Polyester resin or Fluorin carbon resin(PVDF coating);

Core

:non-toxic low density polyethylene core);

Back side

:aluminum alloy sheet coated with primer coating or mill finish aluminum skin;

Core type of the ACP/ACM aluminum composite panel

B grade common breakable quality:when you bend it,it will break;

AB grade good quality:it is better than B grade quality;

AA grade best quality:it is two direction unbreakable when bend it. It is the best quality;

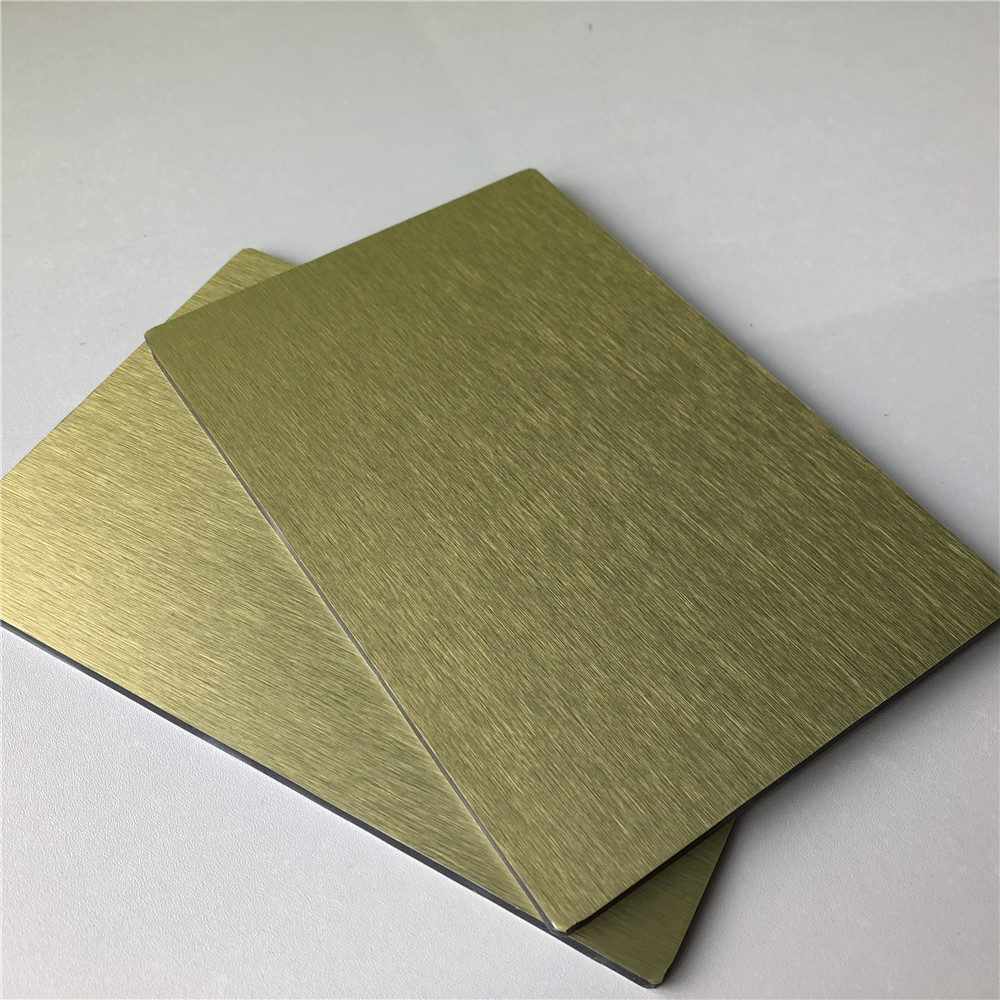

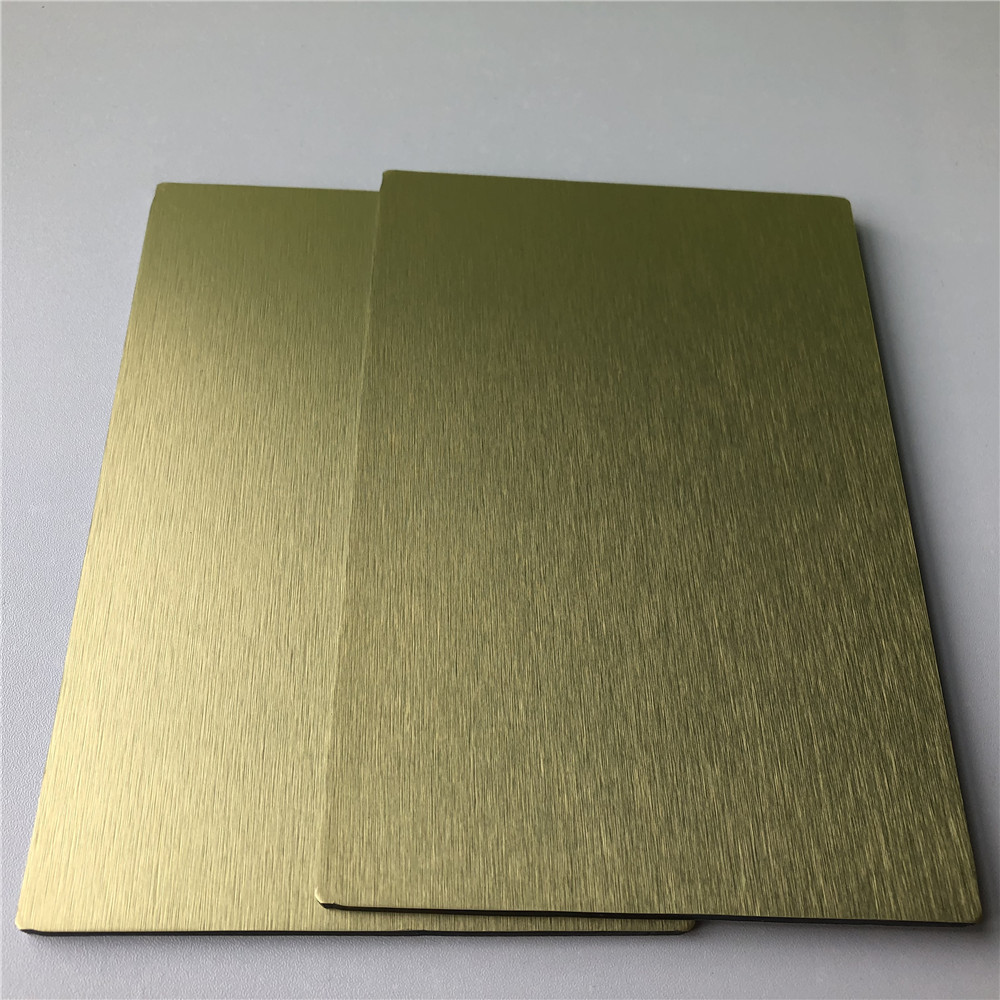

Product picture

ACP advantages

- Lightweight yet sturdy (aluminium and plastic core);

- Chemical/heat/UV resistant (aluminium plates);

- Sound proofing (polyurethane, polyethylene cores). Also helps reduce metallic clanging;

- Thermal insulation (polyurethane, polyethylene cores). Helps normalize temperature inside building;

- Good choice of colours on a smooth surface that last (anodized aluminium);

- Easily installed;

- Easily fabricated to fit many shapes and sizes.

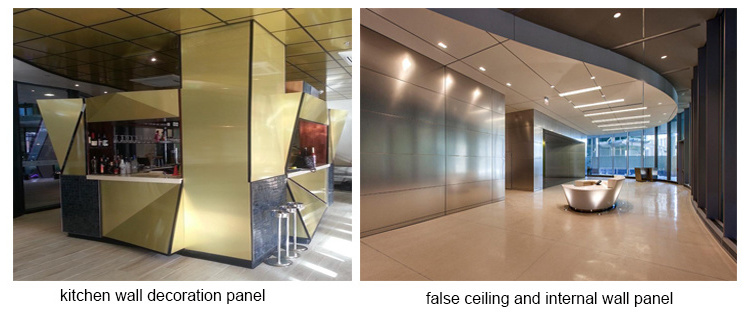

ACP applications

The alu dibond aluminum composit panel clad system is one of the aluminum composite panel with wood finished coating.Applications of ACP are not limited to external building cladding,but can also be used in any form of cladding such as partitions,false ceilings etc. The building material is also widely used within the signage industry as an alternative to heavier,more expensive substrates.

1)Internal Us age: Interior wall,false ceiling,c ubicle kitc hen,bathroom partition wall material,waterproof washing room cladding material etc.

2)External Usage: Building exterior wall,curtain wall board,renovation of old buildings,dust prevention project etc

3) also can be widely used in the signage industry,car wash shop and repair shop wall cladding materials,decoration materials etc

4) Meanwhile the wall sandwich panel has recently also been adopted as a backing material for mounting fine art photography