- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15KW-200KW adjustable

-

Dimension(L*W*H):

-

Customer's Requests

-

Weight:

-

200 KG

-

Material:

-

SUS304/SUS316/red Copper

-

Heating method:

-

Electricity Steam Fire

-

Application:

-

Beer Brewing

-

Thickness:

-

2-3mm / Inside:3.0mm Outside:2mm

-

Control system:

-

Semi-automatic

-

Capacity:

-

500L/batch

-

Insulation:

-

80mm Polyurethane

-

Inner Surface:

-

pickled and passivated

-

Cooling Jacket:

-

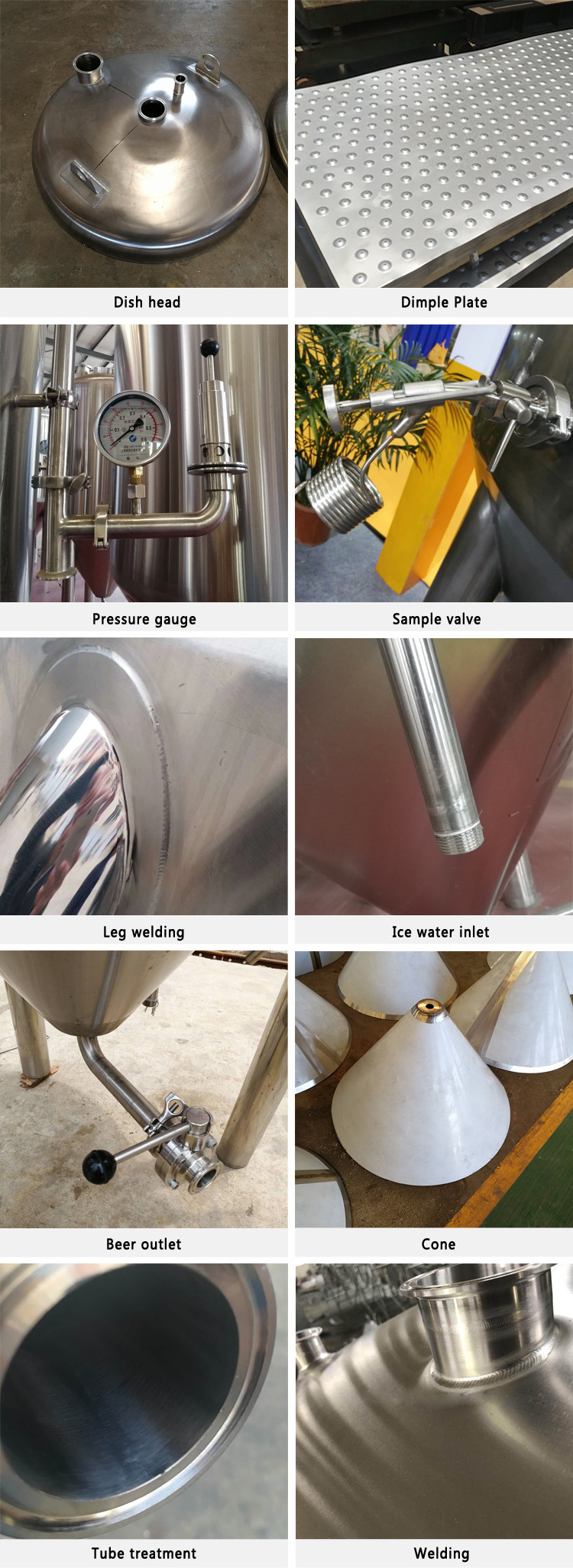

Dimple Cooloing Jacket

-

Product Name:

-

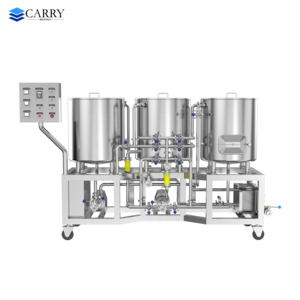

Steam Heating and Direct Fire Beer Brew Brewing Kettles

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ZHBREWING

-

Voltage:

-

110V/220V/240V/350V/380V

-

Power:

-

15KW-200KW adjustable

-

Dimension(L*W*H):

-

Customer's Requests

-

Weight:

-

200 KG

-

Material:

-

SUS304/SUS316/red Copper

-

Heating method:

-

Electricity Steam Fire

-

Application:

-

Beer Brewing

-

Thickness:

-

2-3mm / Inside:3.0mm Outside:2mm

-

Control system:

-

Semi-automatic

-

Capacity:

-

500L/batch

-

Insulation:

-

80mm Polyurethane

-

Inner Surface:

-

pickled and passivated

-

Cooling Jacket:

-

Dimple Cooloing Jacket

-

Product Name:

-

Steam Heating and Direct Fire Beer Brew Brewing Kettles

Products Description

Zunhuang craft beer equipment is consisted of Malt milling system, Mash system, Fermentation system, Refrigeration system, Control system and CIP cleaning system. The tank of the system all adopts Red copper and S.S 304,and the system also have high automatic control capacity.Simple operation.

Equipments characteristics: Small investment, quick effectiveness, high quality, lower prices, the investment repayment is fast, the service life of equipment is long, easy operation, lower cost. Strong technical force.

Equipments characteristics: Small investment, quick effectiveness, high quality, lower prices, the investment repayment is fast, the service life of equipment is long, easy operation, lower cost. Strong technical force.

|

Item |

Capacity |

|

Malt miller |

300-500KG/H |

|

Mashing system

|

3 vessel brewhouse

Mash tun, Lauter tun, Brew kettle&Whirlpool

High beer output and work efficiency.

Heating method can be steam or direct fire. |

|

Fermentation system

|

1000L / 2000L

|

|

Cooling system

|

Glycol water tank + chiller

|

|

Control system

|

PID / PLC

|

|

CIP cleaning system

|

Disinfection tank + alkali tank

|

|

Necessary parts

|

Fitting

|

Fermentation tank:

Zunhuang company are generally use 12 days as fermentation to configured fermenter,And the fermenter adopt two-stage cooling,refrigerant control mode at the end of the cone and the tank level 10--15cm down. So such design and cooling method to control the flow of the cooling liquid state in fermentation tank by the size of the two-stage cooling refrigerant flow. It will improve heat transfer efficiency and cooling rate, faster cooling, and reduce cooling costs and high economic efficiency equipment commercial operation.

Hot Searches