- Product Details

- {{item.text}}

Quick Details

-

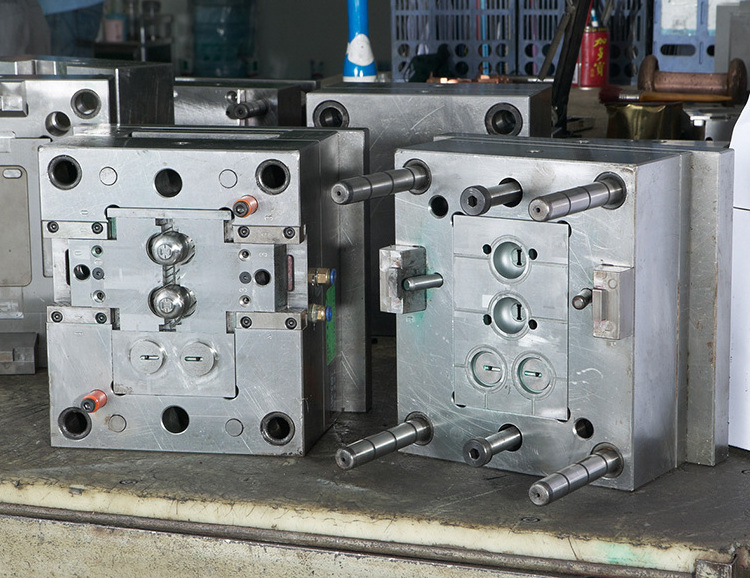

Mold Material:

-

S136&H718 for core,LKM for base

-

Molded parts material:

-

Rubber

-

Cavity:

-

Single/Multi

-

Runner:

-

Hot/Cold runner

-

Gate:

-

Pinpoint gate, Edge gate

-

Mold Life:

-

300,000-1,000,000shots

-

Finish:

-

Semi-matt, Polish

-

Second Processing:

-

Silk-screen printing, Plating, Painting

-

Keyword:

-

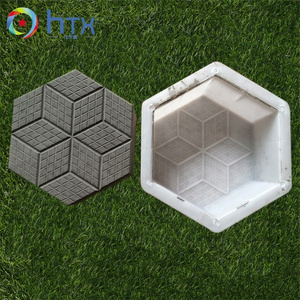

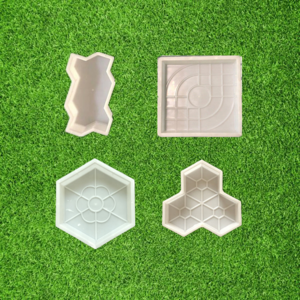

paver block rubber mould

Quick Details

-

Shaping Mode:

-

Rubber mould

-

Place of Origin:

-

Guangdong, China

-

Product name:

-

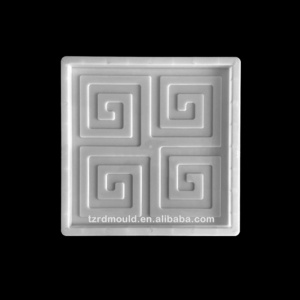

concrete paving material brick pavement paver block rubber mould

-

Mold Material:

-

S136&H718 for core,LKM for base

-

Molded parts material:

-

Rubber

-

Cavity:

-

Single/Multi

-

Runner:

-

Hot/Cold runner

-

Gate:

-

Pinpoint gate, Edge gate

-

Mold Life:

-

300,000-1,000,000shots

-

Finish:

-

Semi-matt, Polish

-

Second Processing:

-

Silk-screen printing, Plating, Painting

-

Keyword:

-

paver block rubber mould

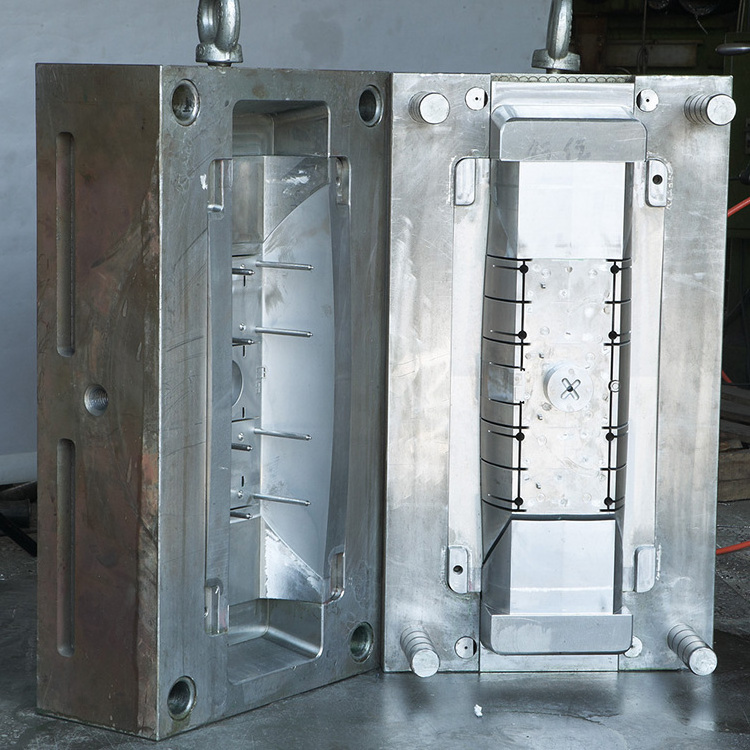

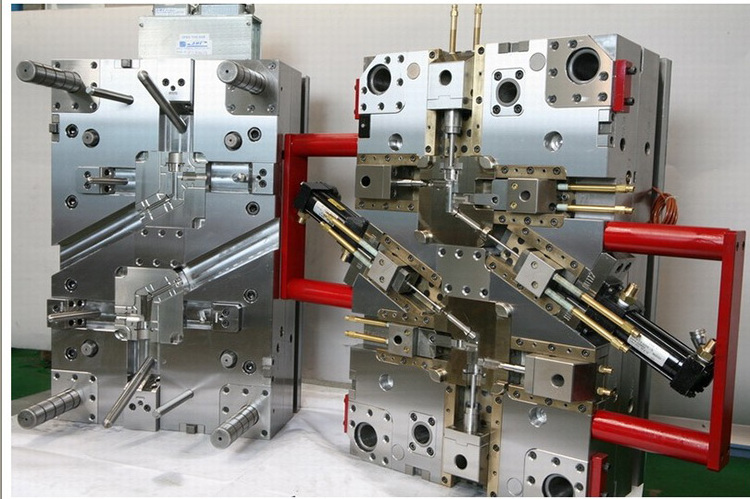

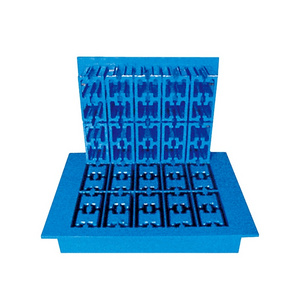

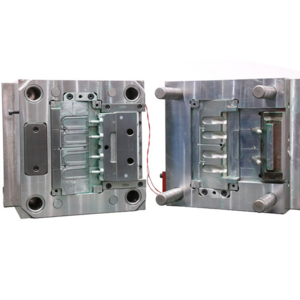

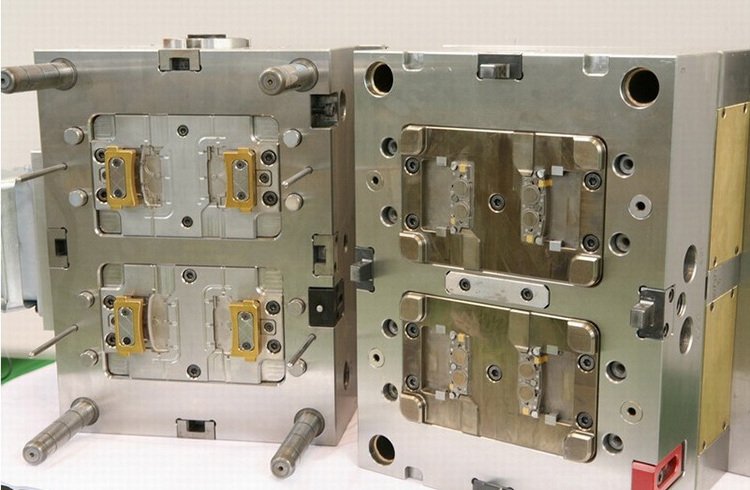

Tooling precast concrete paving material brick pavement paver block rubber mould:

| 1 | Mould base material | LKM, HASCO, LOCAL ,DME, etc |

| 2 | Mould core material | 718H, S136H, NAK80 , P20, etc |

| 3 | Plastic molded parts material | Rubber |

| 4 | Cavity | Single, Multi |

| 5 | Runner | Hot & Cold Runner |

| 6 | Gate | Pin-point gate, Edge gate |

| 7 | Finish | Semi-Matt, Polish |

| 8 | Design software | Pro-E, IGES, UG, CAD CAXA, ect |

| 9 | Main processing equipment | CNC, Cutting, Carved, Milling, EDM |

| 10 | Arrangement type | I-section, Straight body mould |

| 11 | Second Processing | Silk-scree Printing, Plating, Painting |

| 12 | Package |

Wooden case for Plastic casing electronic mould , carton box for inject moulding |

| 13 | Delivery time |

15-45 days for Plastic casing electronic mould and samples. 7days for mass production of inject moulding |

| 14 | Trade Term |

Ex-works, FOB Shenzhen, CIF |

| 15 | Payment Term |

P ayment by T/T |

Follow us to visit our facotry: D ir e ct manufacturer for cost saving and high quality:

7. FAQ

1).What should we offer before start?

We generally work with custom service, which means, please provide 3D drawing in stp, igs format and tell us the specific requirements on material, color, surface treatment and order quantity,

Please provide original samples if no design so we can work on the exact cost and make design for you.

We can also help you to improve and update the design if necessary based on your original samples or design before molding

2). Can we get your free samples?

Yes,you can. Our samples are only free for the customers who confirm the order.But the express freight is on buyer's account.

3).What is the normal lead time?

A.For plastic injection molds,we will send samples to you within 25-30 working days upon receipt of deposit

B.For rubber parts and molds,we will send samples to you within 12-15 working days upon receipt of deposit

C.For metal parts and molds,we will send samples to you within 12-15 working days upon receipt of deposit

4).What is your payment term?

Generally, we work with T/T with 50% deposit for molds and the the balance 50% aganist first samples confirmation

In mass production order, we work with 50% deposit and the balance 50% before shipment

5).What is your shipping way?

We generally work with EXW trade terms.

But we can help you to choose the best shipping way according to your detailed requirements.

6).How do you control the quality?

We will make samples for your confirmation before mass production and follow ISO standard

Do 100% IPQC inspection during production, take photo records from on-site production and final package before shipment

You can send the third party to do inspection if necessary.

7).If any quality problems, how can you deal with it for us?

If any breakage or defect products were found, you must take the pictures from the original carton.

All the claims must be presented within 7 working days after discharging the container. This date is subject to the arrival time of container.

We will advise you to certify the claim by third party, or we can accept the claim from the samples or pictures you present, finally we will completely compensate for all your loss.