- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

700

-

Name:

-

Air Conditioner Radiator Separator

-

Power:

-

3kw+4kw

-

Capacity:

-

300-400kg/h

-

Usage:

-

waste radiator recycle

-

Application scope:

-

19mm,21mm,25mm

-

raw material:

-

waste radiator

-

Weight:

-

700kg

-

Size:

-

1.7*0.8*1.2m

-

Color:

-

as your request

-

Voltage:

-

380V 50Hz

-

After-sales Service Provided:

-

Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

CANMAX

-

Power (kW):

-

7

-

Weight (KG):

-

700

-

Name:

-

Air Conditioner Radiator Separator

-

Power:

-

3kw+4kw

-

Capacity:

-

300-400kg/h

-

Usage:

-

waste radiator recycle

-

Application scope:

-

19mm,21mm,25mm

-

raw material:

-

waste radiator

-

Weight:

-

700kg

-

Size:

-

1.7*0.8*1.2m

-

Color:

-

as your request

-

Voltage:

-

380V 50Hz

-

After-sales Service Provided:

-

Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

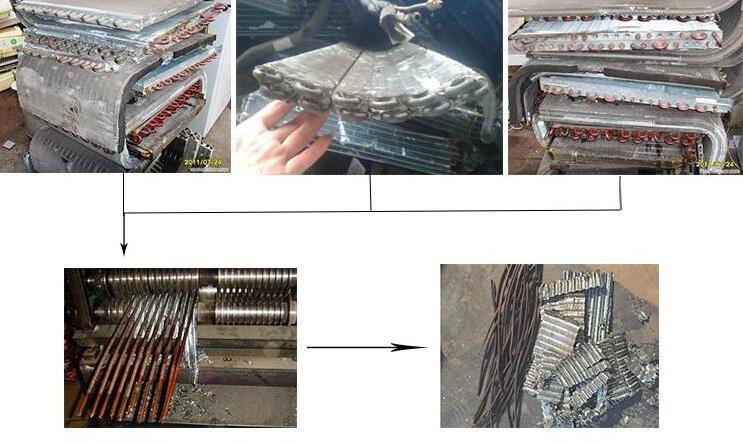

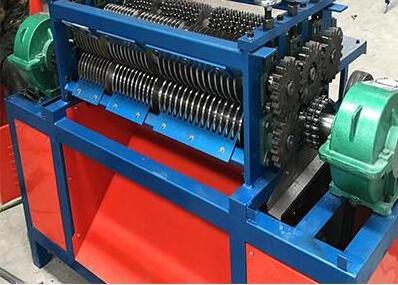

>>>waste radiator crushing machine

is used for separating the outside aluminium foil and the inside copper pipe of wasted air conditioning radiator. Each set of this kind of machine just can separate two different specification radiators. Because the interval width of the copper pipe are different in the radiator, so we need you can offer us the width of the copper pipe of the radiator. In China, the width of the radiator copper pipe is 21MM, 25MM, and 19MM. Besides, the thickness is one layer and two layers.

If the thickness is 3 to 4 layer, the Band Saw Machine is necessary.

| Technical data | |

| Name | Waste waste car radiator crushing machine |

| Model | SSRQ-C3 |

| Power | 3KW+4KW |

| Capacity | 300-400KG/H |

| Size | 1.7*0.8*1.2m |

| Weight | 700KG |

| Process size | 19mm,21mm,25mm |

| Processing size can be customized according to customer requirements | |

>>>Application

Various water tanks, convection radiators, steel radiators, aluminum radiators, copper radiators, stainless steel radiators, copper-aluminum composite radiators, etc., as well as the original cast iron radiators.

>>>Detailed Structure

|

1. Control panel |

| 2. Blade adjuster: w hen process radiators,you need to adjust the distance between blades and radiators,then the processing effect will be good. | |

| 3. operation panel | |

| 4. Bar: It is used to make change from processing one layer to two layer.When this bar shows under the corresponding feeding mouth,it can only process one layer radiator. | |

|

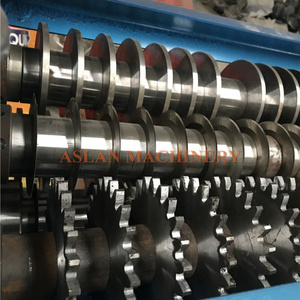

5.Blades :The recycling machine has 69 blades,including 29 small blades and 40 big blades. |

>>>Operation Steps

1. Turn the reversing switch and check the rotating direction.

2. Inject oil into the two oil holes in the left and right side of the machine to lubricate transmission gears (normally once per 4 working hours).

3. Push different radiator into different material inlets according to their specs(19mm,21mm,25mm); the left side of radiators must touch the left side of material inlets; or the right side of radiators must touch the right side of material inlets (the first copper pipe in the lower layer shall be nearer to the guiding ruler,When two-layer radiators are processed, the left side of the radiators shall touch the left side of each Material Inlet, and the first copper pipe in the Upper Layer to the left side of each Material Inlet must be nearer than the first copper pipe in the Lower Layer to the Left Side of each Material Inlet. )

4. After radiators are taken into the machine, copper pipes and aluminum are separated and come out of the machine automatically.

5. According to the layers of radiators and their height, adjust each pair of Adjusting Wheels on the machine (after adjusting, tighten screws below).

>>>Band sawing machine

Our radiator recycling machine can process one layer,two layers and three layer radiators.But the separation effect will be better for one layer and two layer radiator.If your radiator is more than 3 layers,here we recommend you the band sawing machine to cut the radiator into one layer or two layers,to reach a super separation rate.

| Name | Band sawing machine | Picture |

| Model | DJ-500 | |

| Power | 2.2kw | |

| Max.Width of processing | 310mm | |

| Max.thickness of processing | 260mm | |

| Capacity | 500kg/h | |

| Sawing diameter | 500mm | |

| Overall dimension | 900*700*1820mm | |

| Weight | 90kg |

>>>Metal Baler

After the copper and aluminum be separated,you can use the metal baler to bale them.The bale size and wight can be customized as your requirement.

| Model |

Pressure (Ton) |

Press box size (mm) |

bale size (mm) |

capacity (t/h) |

bale weight (kg) |

power (kw) |

weight (T) |

| M63-20 | 100 | 1100*850*450 | 200*200*500 | 0.8-1 | 25 | 15 | 3.2 |

| M63-25 | 120 | 1150*900*550 | 250*250*600 | 1.1-1.3 | 40 | 15 | 3.8 |

| M80-30 | 125 | 1300*950*550 | 300*300*600 | 1.6-2.0 | 60 | 18.5 | 5.2 |

Pre-sale Service

(1) According to the customers' special requirements, provide the most suitable project design, process design and the purchase program.

(2) Guide customers to choose the best and economical plant, recover investment within short time, and site inspection.

On sale service

(1) Welcome you to our factory for a visiting;

(2) Accompany you to check our machine production, quality and the working conditions.

(3) Customize the equipments strictly according to your special requirements and arrange the timely delivery.

After-sale service

(1) Installation guidance

When the machine arrives at your company, we will dispatch our technicians to your factory to guide the installation and commissioning at site.

(2) Technical training

We provide free technical training service to your stuff. Training content contains the main work principle of machine, operating regulations, maintenance methods and steps, safety, etc.

(3) Warranty

Three guarantees of our product quality, warranty for one year (not include man-made damaged). We will maintain the machine for free for the quality problem. If the damage is caused by your improperly operation, the cost of the maintenance burden by you. we also provide you the life-long follow-up service.