- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Processing:

-

block making machinery brick making machinery

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

EBMACH

-

Voltage:

-

380V(Can be customized)

-

Dimension(L*W*H):

-

1250*1350*1600mm

-

Marketing Type:

-

New Product 2022

-

Weight (KG):

-

830 kg

-

MOQ:

-

1

-

LOGO:

-

Can be customized

-

WEIGHT:

-

830KG

-

PLATE SIZE:

-

850*550*30

-

OVERALL SIZE:

-

1200*1280*1950

-

Molding cycle:

-

35S

-

POWER:

-

4.8kw

-

Application:

-

Buliding Construction

-

Color:

-

Can be customized

-

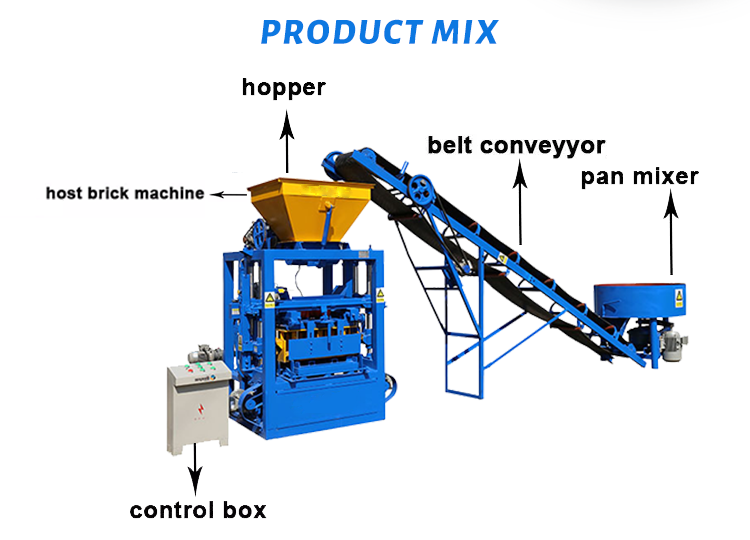

Mixer:

-

Can be customized

Quick Details

-

Type:

-

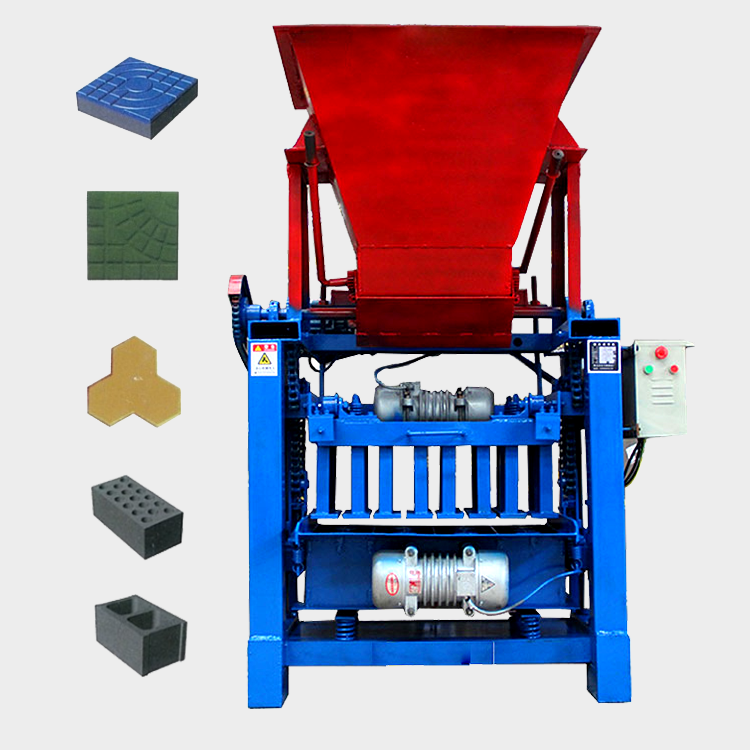

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Autoclaved aerated concrete block (AAC), QT6 concrete blocks making machine

-

Brick Raw Material:

-

Cement, Sand, Crushed Stone, Fly Ash,Pigment, Water

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Processing:

-

block making machinery brick making machinery

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

EBMACH

-

Voltage:

-

380V(Can be customized)

-

Dimension(L*W*H):

-

1250*1350*1600mm

-

Marketing Type:

-

New Product 2022

-

Weight (KG):

-

830 kg

-

MOQ:

-

1

-

LOGO:

-

Can be customized

-

WEIGHT:

-

830KG

-

PLATE SIZE:

-

850*550*30

-

OVERALL SIZE:

-

1200*1280*1950

-

Molding cycle:

-

35S

-

POWER:

-

4.8kw

-

Application:

-

Buliding Construction

-

Color:

-

Can be customized

-

Mixer:

-

Can be customized

Paver Sand And Plastic Earth Block In Ghana Lo Cost Soil Dishgl High Pressure Clay Coimbatore Brick Making Machine

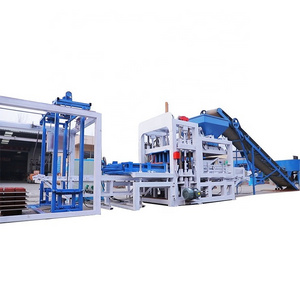

semi-automatic hopper brick machine, 380V voltage, can realize semi-automatic production line through the cooperation of conveyor belt and mixer, which greatly improves the output and saves labor. The utility model has the advantages of simple operation, one machine with multiple functions, and can replace various molds to produce cement products of various specifications

Main Features

1. High vibration ensure high density of the finished products, suitable for solid bricks and pavers.

2. Adopt Japan Omron and France Schneider brand switches, Siemens and ABB brand motors to make high quality machinery.

3. Control PLC: we select original Japan Mitsubishi PLC combine with independently develop machine control program, assure stable and high efficiency working status.

4. Mould: newest heat treatment device and carburizing treatment will assure longer mould life span and ensure the strength of mould reach to 62 HRC so that the mould can be used more than 100 thousand times.

5. Using lower power to realize superior vibratory effects, making various materials to flow-fill and close packing.

1. High vibration ensure high density of the finished products, suitable for solid bricks and pavers.

2. Adopt Japan Omron and France Schneider brand switches, Siemens and ABB brand motors to make high quality machinery.

3. Control PLC: we select original Japan Mitsubishi PLC combine with independently develop machine control program, assure stable and high efficiency working status.

4. Mould: newest heat treatment device and carburizing treatment will assure longer mould life span and ensure the strength of mould reach to 62 HRC so that the mould can be used more than 100 thousand times.

5. Using lower power to realize superior vibratory effects, making various materials to flow-fill and close packing.

|

Molding cycle

|

35S

|

|

Equipped with power(KW)

|

6.3

|

|

Class is produced ( block )

|

Standard brick 240 * 53 * 115mm

Hollow brick 390 * 190 * 190mm

|

|

Plate size(mm)

|

850*550*30

|

|

Overall size

|

1200*1280*1950

|

|

Weight

|

830KG

|

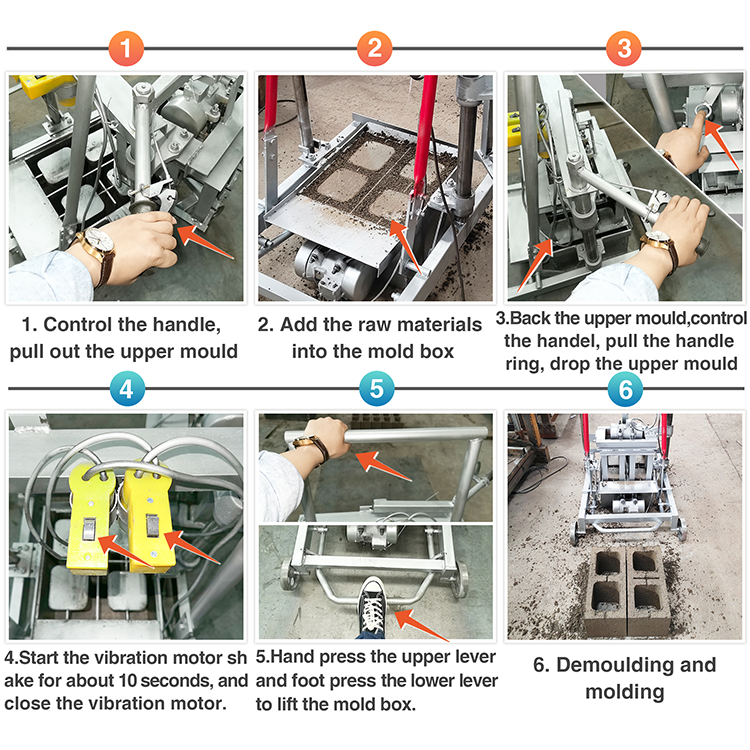

OPERATING INSTRUCTIONS

block making machine Raw material

1. 8-10% cement, 30-40% sand , 50-60% crushed stone.

2.8-10% cement, 30% flyash, 60% sand or stone powder

PRODUCTS ADVANTAGES

Multi-functional:Concrete Block Machine can be used to produce Solid, Porous Hollow Blocks indefferent size and shape

Heavy-duty machine frameConcrete Block Machine uses high-intensity steel and advanced heat treatment which is wear resistant

Concrete Block Machine has top quality painting to make appearance of machines look beautiful and smooth

PRODUCT CATEGORIES

BUYERS FEEDBACK

Henan early bird machinery co.,LTD. located in Zhengzhou, has kept its record in Administration Bureau for Industry and Commerce. The company is a lawful operation. Located in central China, transportation convenience, advanced technology and scientific management guarantee our steady development.We are a large engineering machinery manufacturing enterprise which focuses on research and development, production and sales of mining, tunnel construction, road and bridge construction equipments and so on.We believes that good quality can give us survival, thus we provides you the top products. All the products with high quality meet international standards. Our equipments are highly estimated by the clients, and are well known at home and abroad.

All the staff in our company are professional trained, so we are familiar with the products and can recommend you the most appropriate equipment.

WHY CHOOSE US

FAQ

Q: What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll send you photos of the products and packages before you pay the balance.

Q: What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q: How about your delivery time?

A: Generally it takes 7-10 workdays after we received your advance payment. The specific delivery time depends on the items and the quantity.

Q: What is the warranty?

A: We provide a 1-year warranty (except for the hammer) for the machines, during this period all broken accessories can be changed for a new one. And we provide instructions for machine install and operation.

Q: What is your terms of packing?

A: Generally we use standard wooden case for LCL goods, and fixed well for FCL goods.

Q: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery. And we will send you the inspection report for every machine.

Q: Do you provide wear parts?

A: Yes, all kind of wear parts are available.

Hot Searches