- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

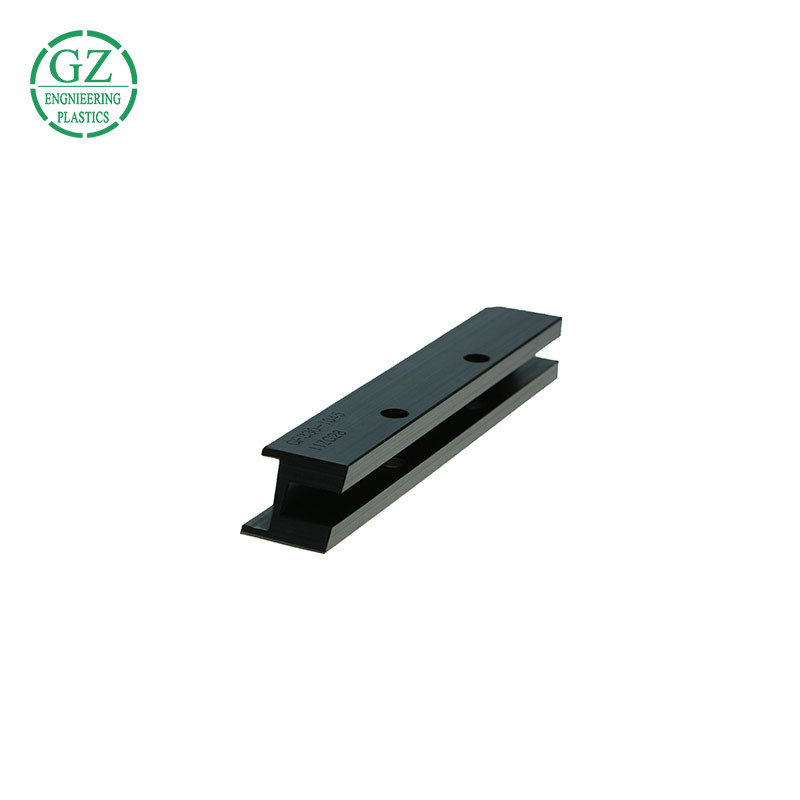

v track roller guide rail

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GZ engineering plastics

-

Material:

-

Pom,Nylon,UhmwPe

-

Product name:

-

Customized good wear resistance v track roller guide rail

-

Name:

-

v track roller guide rail

-

Certification:

-

ISO9001

-

Process:

-

CNC Machining

-

Quality Control:

-

100% Inspection

-

Drawing Formats:

-

CAD

-

Packing:

-

wooden box

-

MOQ:

-

10pcs

-

function:

-

slide transmission

-

After Warranty Service:

-

Online support

Quick Details

-

Weight (KG):

-

2

-

Marketing Type:

-

New Product 2021

-

Core Components:

-

guide

-

Model Number:

-

v track roller guide rail

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GZ engineering plastics

-

Material:

-

Pom,Nylon,UhmwPe

-

Product name:

-

Customized good wear resistance v track roller guide rail

-

Name:

-

v track roller guide rail

-

Certification:

-

ISO9001

-

Process:

-

CNC Machining

-

Quality Control:

-

100% Inspection

-

Drawing Formats:

-

CAD

-

Packing:

-

wooden box

-

MOQ:

-

10pcs

-

function:

-

slide transmission

-

After Warranty Service:

-

Online support

|

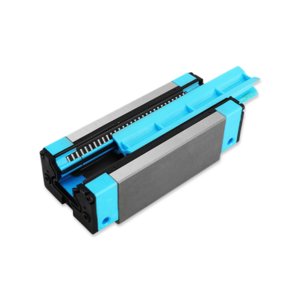

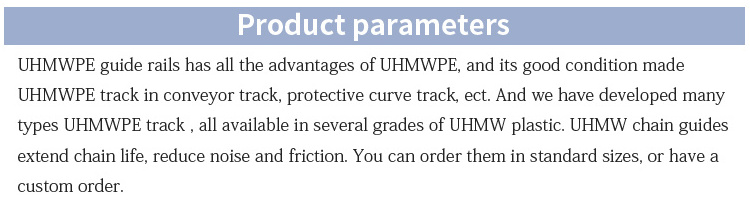

Product name

|

|

Chain guide

|

|

|

|||

|

Color

|

|

Green/Blue/Black

|

|

|

|||

|

Material

|

|

UHWMPE

|

|

|

|||

|

Length

|

|

Standard/as your requirement

|

|

|

|||

|

Type

|

|

T type, CT type, TU type, TS type, CTS type, U type, CU type, K type, CK type, CKG type, CKG 14H type, CKG 15V type, CKG 16H type, ETA type, R type CRG type

|

|

|

|||

|

Chain type

|

|

Simplex, duplex, triplex

|

|

|

|||

|

Application

|

|

Machinery industry/medical apparatus/mining industry/ Catering light industry ect

|

|

|

|||

|

Material Advantage

|

|

1. High wear resistance 2. High impact strength 3. Good self lubrication 4. High chemical stability 5. Completely hygienic and non-toxic, can be used in contact with food and medicine

|

|

|

|||

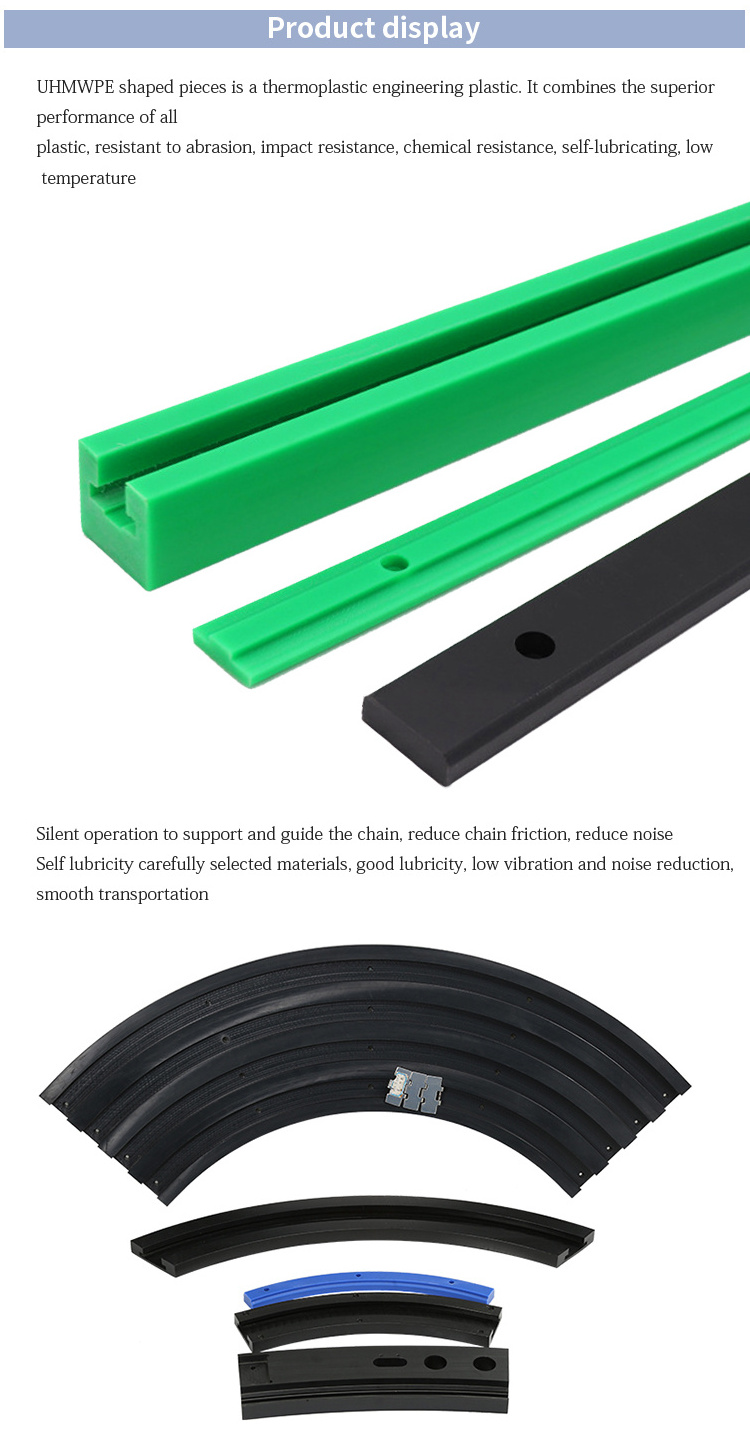

Prduct Display

Application Field

Why choose us

professional team

Our Factory

FAQ

Q1. Can samples be produced?

A1. Yes

Q2. What is the accuracy of the products processed by the drawings?

A2. Different equipment has different accuracy, generally between 0.05-0.1

Q3. What craftsmanship do you have for processing accessories?

A3. According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q4. What are your processing equipment?

A4. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine, extruder, molding machine

Q5. Can you help assembling the product after it is made?

A5. It's okay

Q6. What certifications or qualifications does your company have?

A6. Our company’s certificates are: ISO, ROHS, product patent certificates, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. It is ok. Surface treatment: spray paint, silk screen, electroplating, etc.

Hot Searches