With galvanization, a piece of industrial steel is expected to last more than 50 years in average environments, and can last over

20 years with severe water exposure. There is no maintenance required. The increased durability of the steel’s finished product

also increases the product’s reliability.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Hardness:

-

Full Hard

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JUHE

-

Width:

-

10-600mm, 600-1500 mm

-

Grade:

-

DX51D

-

Surface Treatment:

-

Custom

-

Coil Weight:

-

3-8 Tons

-

Package:

-

Standard Sea Worthy Package

-

Product Name:

-

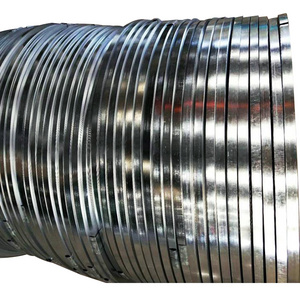

Z100g galvanized steel sheet metal roll iron strip gi coils

Quick Details

-

Thickness:

-

0.12-2.5mm, 0.12-6mm

-

Coating:

-

Z41-Z60

-

Technique:

-

Cold Rolled Based

-

Hardness:

-

Full Hard

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JUHE

-

Width:

-

10-600mm, 600-1500 mm

-

Grade:

-

DX51D

-

Surface Treatment:

-

Custom

-

Coil Weight:

-

3-8 Tons

-

Package:

-

Standard Sea Worthy Package

-

Product Name:

-

Z100g galvanized steel sheet metal roll iron strip gi coils

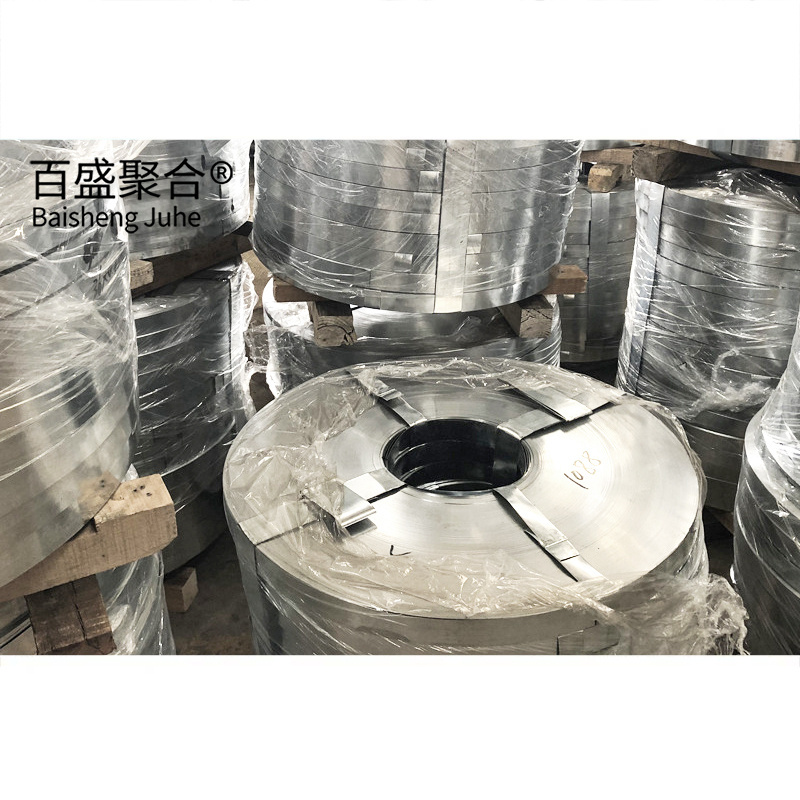

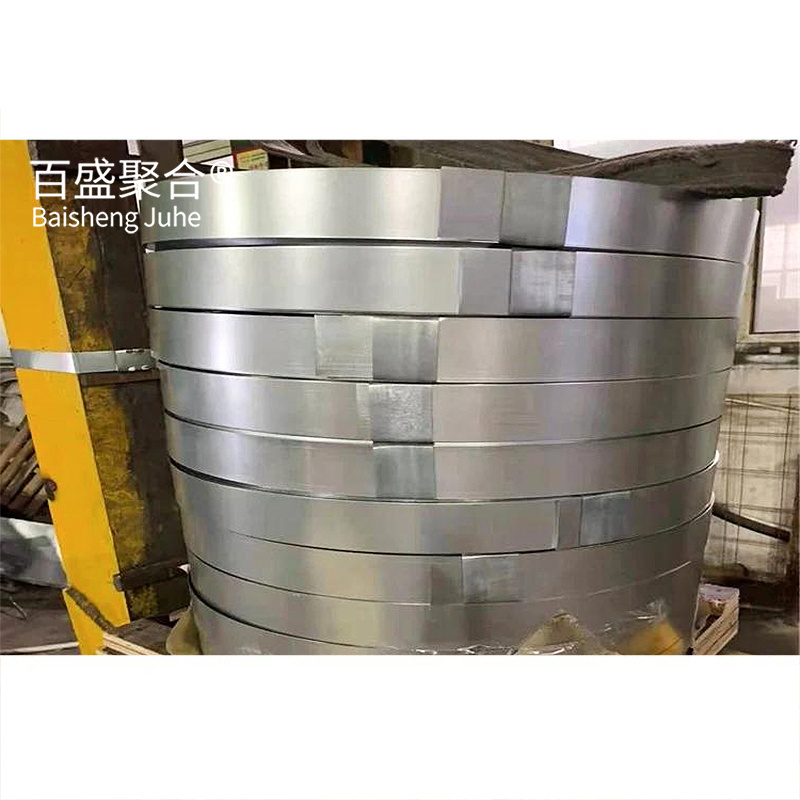

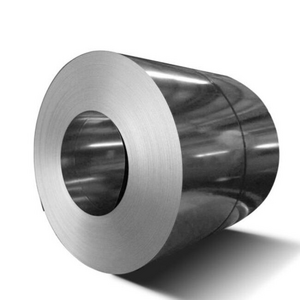

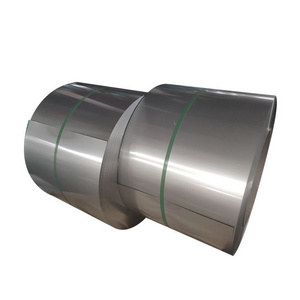

Products Description

产品标题

Galvanized strip is a long, narrow strip of cold or hot rolled steel coated in varying degrees with a material called (zinc, aluminum). Hot dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Complex physical and chemical reactions occur between hot-dip galvanized strip steel matrix and molten bath to form a tight zn-fe alloy layer with corrosion resistance. The alloy layer is integrated with the pure zinc layer and the strip matrix. Therefore, its corrosion resistance is strong.

|

Standard

|

AISI,ASTM,GB,JIS

|

Material

|

SGCC,S350GD+Z,S550GD+Z,DX51D,DX52D,DX53D

|

|||

|

Thickness

|

0.16-5mm

|

Width

|

25-1500mm

|

|||

|

Tolerance

|

+/-0.02mm

|

Zinc coating

|

60-275g/m2

|

|||

|

Coil ID

|

508-610MM

|

Coil Weight

|

3-8 tons

|

|||

|

Technique

|

Hot rolled, cold rolled

|

Package

|

seaworthy package

|

|||

|

Certification

|

ISO 9001-2008,SGS,CE,BV

|

MOQ

|

25 TONS (in one 20ft FCL)

|

|||

|

Delivery

|

15-20 days

|

Monthly Output

|

10000 tons

|

|||

|

Surface treatment:

|

oiled, passivation or chromium-free passivation, passivation+oiled, chromium-free passivation+oiled, resistant to fingerprints or

chromium-free resistant to fingerprints |

|

|

|||

|

Spangle

|

regular spangle,minimal spangle, zero spangle,big spangle

|

|

|

|||

|

Payment

|

30%T/T in advanced+70% balanced;irrevocable L/C at sight

|

|

|

|||

|

Remarks

|

Insurance is all risks and accept the third party test

|

|

|

|||

|

Mechanical properties of galvanized steel

|

|

|

|

|||

|

Usage

|

Grade

|

Yield strength(MPa)

|

Tensile strength(MPa)

|

|||

|

Punching galvanized steel

|

DC51D+Z

|

-

|

270-500

|

|||

|

|

DC52D+Z

|

140-300

|

270-420

|

|||

|

|

DC53D+Z

|

140-260

|

270-380

|

|||

|

Structure galvanized steel

|

S280GD+Z

|

≥280

|

≥360

|

|||

|

|

S350GD+Z

|

≥350

|

≥420

|

|||

|

|

S550GD+Z

|

≥550

|

≥560

|

|||

Technological production process

The production process of cold rolled strip is generally as follows: pickling → rolling → process lubrication → annealing → leveling → cutting → packaging.

Cold rolling process: pickling -- rolling -- annealing -- synchronous lubrication of rolling size -- anti-rust oil -- leveling and sizing -- polishing -- packaging

Heating furnace of hot rolled strip steel: - phosphorus removal machine, roughing mill, phosphorus removal machine, finishing mill, surface quality inspection instrument - layer of cold - reel, baling machine, injection machine - volume base slab.

Product Advantage

Long Life-span

Rust Resistance

From the zinc coating. The iron elements in steel are incredibly prone to rusting, but the addition of zinc acts as a protective buffer between the steel and any moisture or oxygen. Galvanized steel is very protective, including sharp corners and recesses that couldn’t be protected with other coatings, making it resistant to damage.

The Sacrificial Anode

The sacrificial anode ensures that any damaged steel is protected by the surrounding zinc coating. It doesn’t matter if the steel

section is completely exposed; the zinc will still corrode first. The coating will corrode preferentially to the steel, creating a

sacrificial protection to the areas that are damaged.

If you need more info, please feel free to contact us. → → →

Contact Us >

Chemical Composition

Galvanized Steel 0.18mm-20mm thick galvanized steel sheet 2mm thick Hot dip galvanized steel sizes galvanized sheet metal roll

|

Chemical

Compose

|

Grade

|

C %

|

Si %

|

Mn %

|

P %

|

S %

|

||

|

|

Q195

|

≤0.12

|

≤0.30

|

≤0.50

|

≤0.035

|

≤0.035

|

||

|

|

Q235

|

≤0.22

|

≤0.35

|

≤1.4

|

≤0.035

|

≤0.035

|

||

|

|

DX51D

|

≤0.12

|

≤0.50

|

≤0.60

|

≤0.1

|

≤0.045

|

||

|

|

SGCC

|

≤0.15

|

-

|

≤0.80

|

≤0.05

|

≤0.03

|

||

|

Mechanical

Property

|

Grade

|

Yield Strength

MPA

|

|

Tensile Strength

MPA

|

|

Elongation

|

||

|

|

Q195

|

≥195

|

|

315-430

|

|

22%

|

||

|

|

Q235

|

≥235

|

|

370-500

|

|

19%

|

||

|

|

DX51D

|

-

|

|

270-500

|

|

22%

|

||

|

|

SGCC

|

≥205

|

|

≥270

|

|

22%

|

||

Steel belt is a large output, wide use, variety of steel. According to the processing method, it can be divided into hot rolled strip and cold rolled strip. According to their thickness, they can be divided into thin steel strip (thickness no more than 4mm) and thick steel strip (thickness greater than 4mm); According to the width, it is divided into wide steel belt (width is greater than 600mm) and narrow steel belt (width is less than 600mm); Narrow steel strip is divided into direct rolling narrow steel strip and narrow steel strip by longitudinal shear of wide steel strip; According to the surface state, it can be divided into original rolling surface and plating (coating) surface steel strip. According to the use, it can be divided into general and special (such as hull, bridge, oil drum, welded pipe, packaging, self-generated car, etc.) steel belt.

Galvanization is the leading method to protect metals from environmental elements that cause corrosion, rust, and the eventual weakening of the steel. Hot-dip galvanizing deposits a thick, robust layer of zinc iron alloys on the surface of a steel item. When exposed to the atmosphere, pure zinc reacts with oxygen to form zinc oxide which further reacts with carbon dioxide to form zinc carbonate.

Galvanized narrow strip

Spangle is formed during the hot-dip galvanizing process. The size, brightness, and surface of spangles mainly depend on the composition of zinc layer and the cooling method. According to the size, it includes small spangles, regular spangles, big spangles, and free spangles. They look different, but the spangles almost will not influence the quality of galvanized steel. You can choose according to your preference and purpose.

product testing

Application areas

1. The board surface is flat, the spangles are even, and the color is bright;

2. Galvanized steel strip has the characteristics of anti-corrosion, strong tensile performance, and fire resistance;

3. The produced galvanized steel strip is beautiful, economical and durable;

4. The galvanized layer has good adhesion to the steel plate, is rust-proof and durable, and does not fall off;

5. As raw materials for a series of building materials, such as light steel keels, galvanized pipes, fire-resistant rolling doors,

civil materials and other industries.

Hot Searches