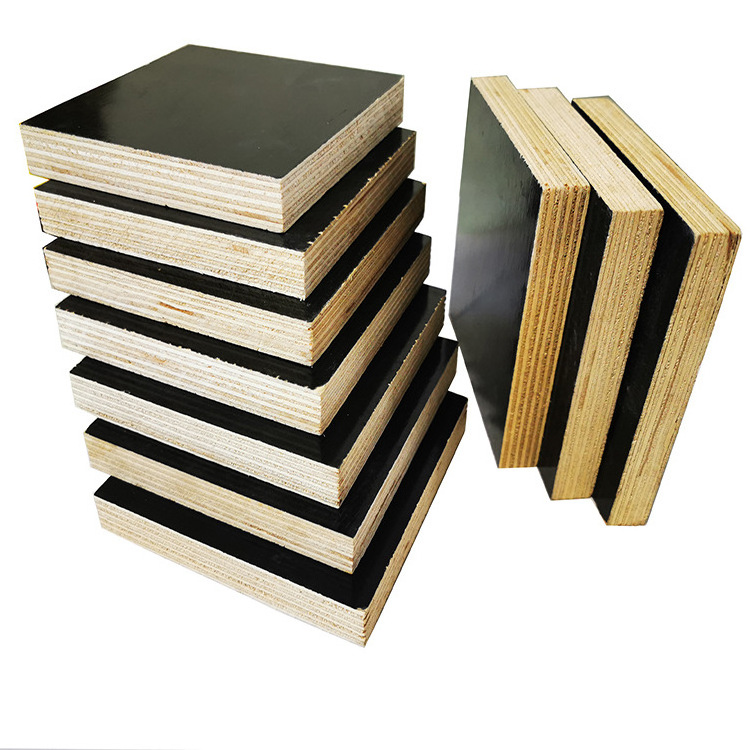

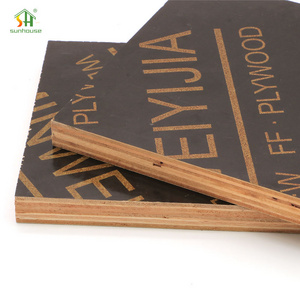

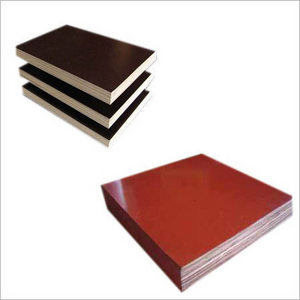

Adopts layer by layer over gluing and full bonding, which improves the gluing strength by 5-10%.

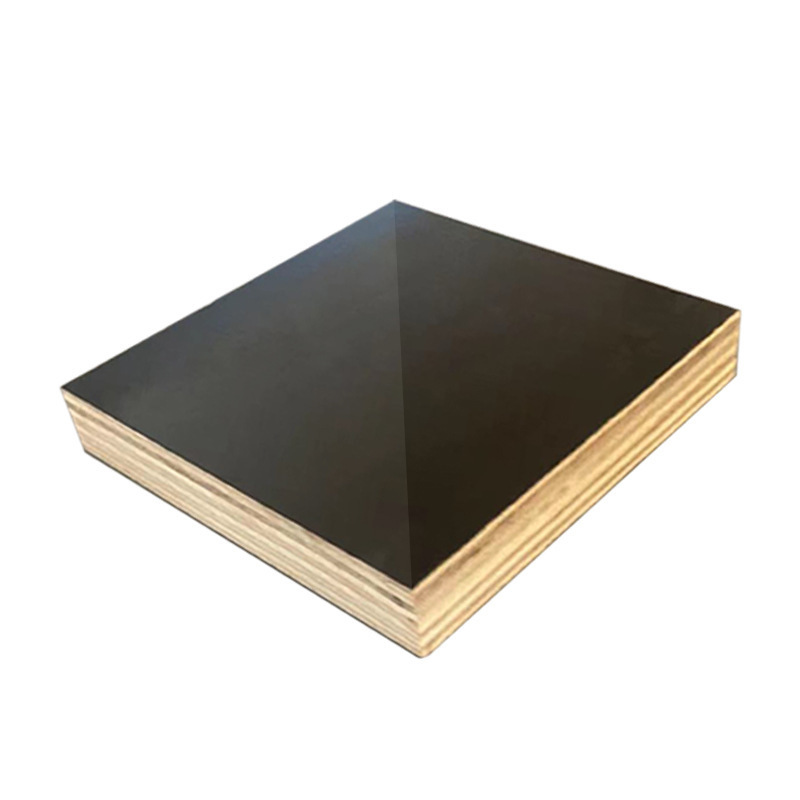

After steaming in boiling water for 120 minutes, still able to achieve the bonding strength requirements.