- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

11m*2.0m*3.0m

-

Voltage:

-

220v-10kv

-

Power:

-

70000-80000

-

Weight (KG):

-

20000

-

Product Name:

-

Coconut Shell Coal Making Machine

-

Color:

-

Gray, Orange or Customized

-

Output Capacity(kg/h):

-

1400-2900

-

Inner layer Diameter(mm):

-

1000-2900

-

Outer layer Diameter(mm):

-

1600-2900

-

The Drum Length(m):

-

10-12

-

Feeding Way:

-

Automatic frequency conversion feeding

-

Control Cabinet:

-

PLC automatic control cabinet

-

Equipped With:

-

Cooling discharging machine

-

Raw Material:

-

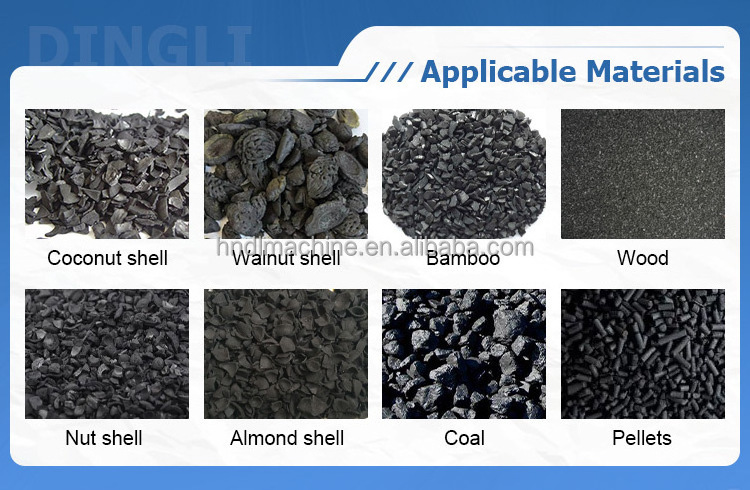

Wood Sawdust, Rice Husk, Crops Straw, Jute Sticks

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DINGLI

-

Effective Volume:

-

Customized

-

Dimension(L*W*H):

-

11m*2.0m*3.0m

-

Voltage:

-

220v-10kv

-

Power:

-

70000-80000

-

Weight (KG):

-

20000

-

Product Name:

-

Coconut Shell Coal Making Machine

-

Color:

-

Gray, Orange or Customized

-

Output Capacity(kg/h):

-

1400-2900

-

Inner layer Diameter(mm):

-

1000-2900

-

Outer layer Diameter(mm):

-

1600-2900

-

The Drum Length(m):

-

10-12

-

Feeding Way:

-

Automatic frequency conversion feeding

-

Control Cabinet:

-

PLC automatic control cabinet

-

Equipped With:

-

Cooling discharging machine

-

Raw Material:

-

Wood Sawdust, Rice Husk, Crops Straw, Jute Sticks

Activated Carbon Regeneration Furnace

Activated carbon regeneration furnace refers to the use of physical or chemical methods to remove the adsorbate adsorbed on the activated carbon and restore its adsorption performance without destroying the original structure of the activated carbon, so as to achieve the purpose of repeated use. Modified activated carbon materials are widely used in the field of sewage treatment, and have increasingly shown their attractive prospects in the treatment of water environmental pollution.

Equipment Warrior

Activated carbon regeneration furnace, activated carbon regeneration equipment, and activated carbon regeneration device are

mainly composed of the main body of the regeneration furnace, a steam pore maker, etc.

mainly composed of the main body of the regeneration furnace, a steam pore maker, etc.

|

Model

|

Capacity(kg/h)

|

Size(m)

|

|

DLAGK0.6

|

300-500

|

10*1.1*1.2

|

|

DLAGK0.8

|

400-600

|

12*1.3*1.5

|

|

DLAGK1.0

|

500-800

|

12*1.5*1.7

|

|

DLAGK1.5

|

700-1200

|

14*1.7*1.8

|

|

DLAGK1.6

|

1000-1500

|

14*2*2.2

|

|

DLAGK1.8

|

1500-1800

|

17*2.1*2.2

|

|

DLAGK2.0

|

1800-2500

|

20*2.3*2.5

|

|

DLAGK2.0

|

2700-3200

|

20*2.5*2.7

|

|

DLAGK2.2

|

3200-4000

|

20*2.7*2.8

|

|

DLAGK2.5

|

4000-5000

|

20*3*3.1

|

|

DLAGK3.0

|

5000-6000

|

20*3.5*3.8

|

1. External heating, the material is heated evenly: the activation furnace adopts external heating, the main feature is that the material is not in contact with oxygen and open flame, and the material has no ablation;

2. High degree of automation: the form of continuous feeding and continuous discharging realizes fully automated production, greatly reduces work intensity, and improves the reliability of equipment;

3. The activation reaction is controlled accurately: the activation converter can control the activation reaction of the material more accurately, so as to better control the pore size distribution of the material;

4. Low energy consumption: a large amount of volatile gas contained in the material is directly introduced into the furnace for full combustion, providing the required heat for material activation.

2. High degree of automation: the form of continuous feeding and continuous discharging realizes fully automated production, greatly reduces work intensity, and improves the reliability of equipment;

3. The activation reaction is controlled accurately: the activation converter can control the activation reaction of the material more accurately, so as to better control the pore size distribution of the material;

4. Low energy consumption: a large amount of volatile gas contained in the material is directly introduced into the furnace for full combustion, providing the required heat for material activation.

Hot Searches