- Product Details

- {{item.text}}

Quick Details

-

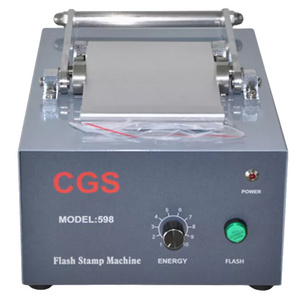

Name:

-

Mini rubber stamp machine

-

Quantity of Exposure Tube:

-

2

-

Flash Energy:

-

1800J

-

Weight:

-

12kg

-

Machine size:

-

38*26*9cm

-

packing size:

-

48*37*21cm

-

Maximum Exposure Area:

-

140 x 80mm

-

Power Supply:

-

AC 220V/50Hz 10%/-10%

-

Warranty:

-

one year

-

Application Industry:

-

Making cartoon stamp, product packaging stamp,etc

Quick Details

-

Brand Name:

-

Disen

-

Model Number:

-

DS-stamp-19

-

Place of Origin:

-

Guangdong, China

-

Name:

-

Mini rubber stamp machine

-

Quantity of Exposure Tube:

-

2

-

Flash Energy:

-

1800J

-

Weight:

-

12kg

-

Machine size:

-

38*26*9cm

-

packing size:

-

48*37*21cm

-

Maximum Exposure Area:

-

140 x 80mm

-

Power Supply:

-

AC 220V/50Hz 10%/-10%

-

Warranty:

-

one year

-

Application Industry:

-

Making cartoon stamp, product packaging stamp,etc

|

Customer First Service First |

|

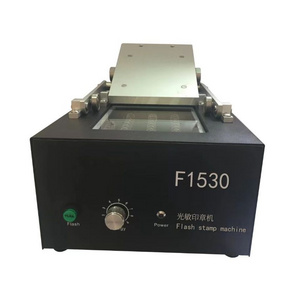

CO2 Laser Photosentative Engraving Machine

Technical Index:

Application Industry:

Applications:

About photosensitive seal machine

Photosensitive seal machine (commonly known as photosensitive seal machine engraving machine portrait wedding stamp engraving machine) photosensitive seal as is currently the internationally latest a seal, with its production of simple and quick, clear seal, long life, applicability, in our rapidly promotion, and has become the seal industry upgrading of products. With standard GA241.9--2000 ** Department of promulgation and implementation of photosensitive seal machine has been identified as the preferred standard seal machine. The product has produced convenient (ie given that customers can do, Lidengkequ), continuous seal thousands of times, the Indian side does not shrink, no deformation, imprinting a clear non-proliferation, non-fading ink lasting, continuous oiling, continuous use. Can produce 0.1 mm anti-counterfeiting stripes. Separate exposure box design, alignment precision. Exposure efficient, full of energy, machinery and lighter weight. Overall appearance, simple operation, all chapters pad once exposure molding, durable.

Photosensitive seal Working principle Photosensitive seal machine basic principle is to use a special photosensitive material, the seal is formed where the surface layer without imprinting can not penetrate the membrane, so as to effect the seal. Therefore, the use of photosensitive seal seal produced faster. Photosensitive seal machine advantage is cheap and not easily broken, imprinted clear text, high precision, easy to use, takes only 10 seconds exposure process. Not every time stamped dip inks, Zhang body and generous beautiful and durable.

Photosensitive seal machine related methods of operation

1 ) with a laser printer will produce a good proofs printed on parchment paper or film .

Photosensitive seal machine production knowledge and precautions

Note:

1) The instrument contains high voltage, do not arbitrarily open the cabinet, if fault, please contact us.

Photosensitive seal machine and laser seal machine difference

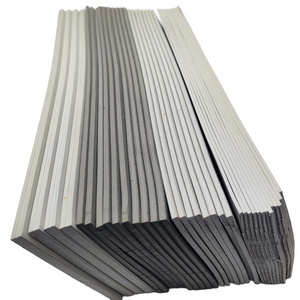

Laser engraving machine is to rely on laser tube generates a laser, the laser portable hot at the chapter material on progressive scan engraving, laser engraving machine can be plastic, horn, organic and other hard materials carving; photosensitive engraving machine is the use of the optical principle of the text, graphics by exposing photosensitive printed in a special mat, photosensitive seal machine can only do in a special light-sensitive pad, photosensitive machine timber costs are relatively higher, but the machine low price, small size, clean, made out of clear seal so much welcomed; laser seal machine with cheap raw materials, affordable, in addition to ordinary seal engraving, you can engrave million times imitation Stamps and India and other! Secondly, laser engraving machine price than photosensitive machine prices more expensive, but the laser engraving machine consumables prices and supplies photosensitive seal contrast, photosensitive seal supplies and higher prices.

|

|

Customer First Service First |

|

Mini rubber stamp machine

Mini rubber stamp machine

Mini rubber stamp machine

Mini rubber stamp machine

Mini rubber stamp machine

Mini rubber stamp machine

Mini rubber stamp machine

|

| Customer First Service First |

|

flash stamp machine Pre ink rubber stamp machine Mini rubber stamp machine Flash lamp for flash stamp machine

In order to seal all light pads can be accurately exposed , the machine can be displayed according to the voltage meter free random exposure means exposure . Exposure voltage range from 160V to 320V between the exposure can . ( Initial use , it is recommended to test out first with scrap pad suitable for this chapter the best exposure voltage value , such as photosensitive pad for some domestic exposure voltage value: sulfuric acid paper printout 240V, film print version 220V). Subject photosensitive machine charging indicator reaches the desired exposure of the chapter pad voltage , power off, press the exposure button to complete the exposure.

Laser stamp machine problems and solutions

Why laser stamp machine is working properly , the engraving parameters correctly, but the effect is not good carving ?

Laser stamp machine is used to note a few things

( 1 ) using the automatic measurement focus , pay attention to automatic measurement of coke rods must be tightened , otherwise the work surface to the top of the laser head , and make it out of orbit .

Computer engraving machine laser processing is the most advanced processing technology, it is mainly the use of efficient laser material for carving and cutting , the main equipment including computers and laser engraving machine ( cutting machine ) , the use of laser engraving and cutting process is very simple, as with computer and printer to print on paper , in the use of a variety of graphics software (CorelDraw, Photoshop, CAD) for graphic design, you will be transferred to the graphic laser engraving machine , laser engraving machine can be easily carved into any graphic material surface, and according to the design requirements of the cutting edge .

Laser processing advantages:

Mechanical engraving is not common in a cost-effective way of carving irregular forms the point, because of not having gray. Laser engraving machine is realized by dot carving, shows the economic natural advantages in gray. Therefore in the carving design as far as possible the use of gray forms, the benefits of this is on the one hand reduces the coloring process, saving the cost; on the other hand, rich carving performance means, added graphics level. Users in the use of, the graphics do different gray fill, carving output select monochrome mode, can try different dot effect, accuracy is generally not more than 500dpi.

|

| Customer First Service First |

|

|