- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v or customized

-

Dimension(L*W*H):

-

depends

-

Weight:

-

500 KG

-

Product name:

-

sprical chute

-

Outside diameter:

-

400,600,900,1200,1500,2000mm

-

pitch:

-

180-1200mm

-

Pitch dia ratio:

-

0.45-0.75

-

lateral slope:

-

9°

-

Material:

-

fiberglass

-

Application:

-

Mining

-

Installation:

-

Engineer Guide

-

Transmission mechanism:

-

eccentric linkage

-

maximum starts per colum:

-

2-4

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC

-

Voltage:

-

380v or customized

-

Dimension(L*W*H):

-

depends

-

Weight:

-

500 KG

-

Product name:

-

sprical chute

-

Outside diameter:

-

400,600,900,1200,1500,2000mm

-

pitch:

-

180-1200mm

-

Pitch dia ratio:

-

0.45-0.75

-

lateral slope:

-

9°

-

Material:

-

fiberglass

-

Application:

-

Mining

-

Installation:

-

Engineer Guide

-

Transmission mechanism:

-

eccentric linkage

-

maximum starts per colum:

-

2-4

Product Description

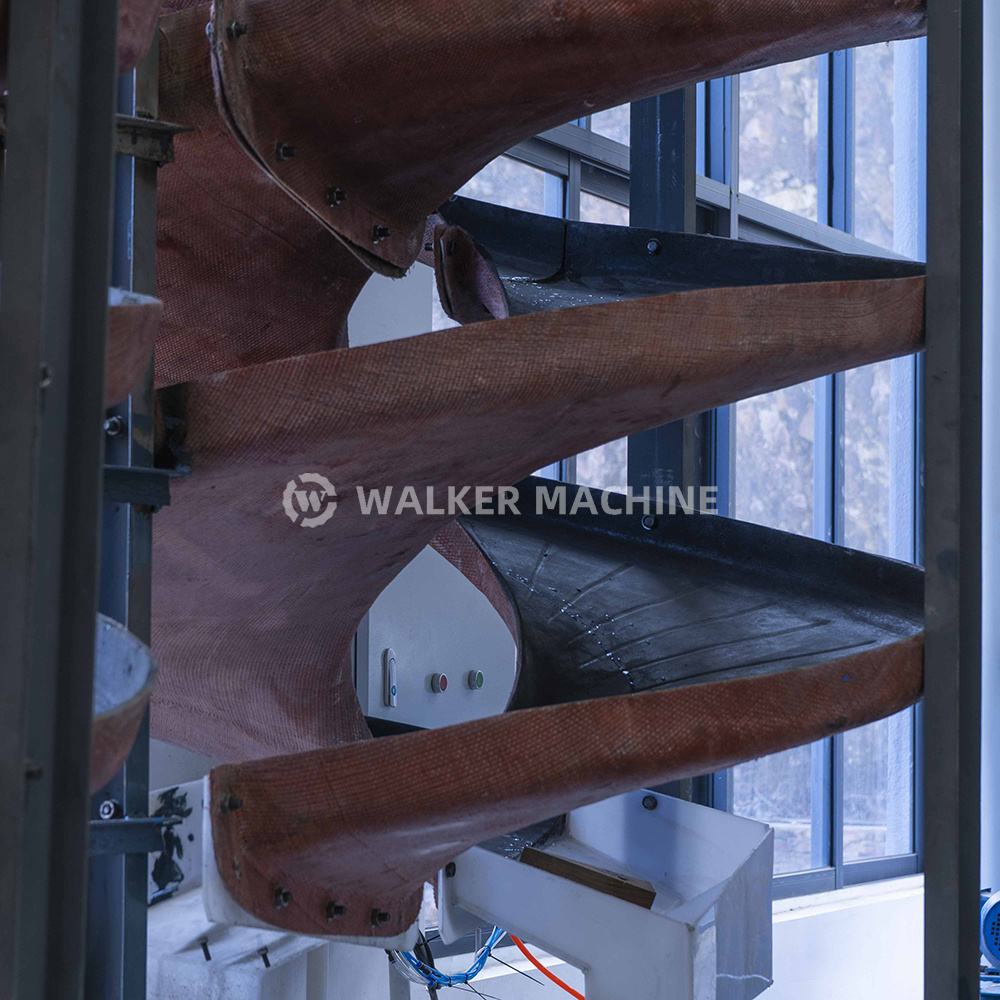

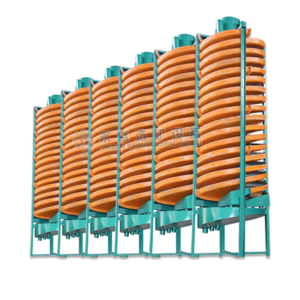

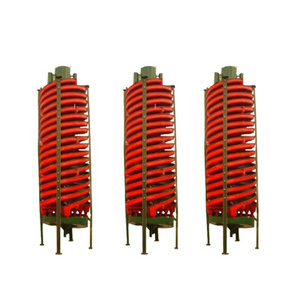

Introduction of spiral chute

Walker mechanical spiral separator can be used for gold, copper, tungsten, tin, tantalum, coltan, chromium, zinc ore and other minerals beneficiation. With over 30 years of experience in manufacturing mining machinery, when you find us, you have found one of the best mining machinery manufacturers.

Features of spiral chute

1. Reasonable structure and small occupation area

2.High recovery, high efficiency, and precise separation

3. Non-required power

4.Light in weight, anti corrosion, rust and wear resistant

5. Simple installation and Minimal maintenance requirements

6. Low operating cost and long working life

7. Reliable running with minimal operator attention

8. Strong adaptability to fluctuation of feeding amount, density, size and grade

9. The surface of corundum forms strong friction the concentration effect surpass plastic surface

1. Reasonable structure and small occupation area

2.High recovery, high efficiency, and precise separation

3. Non-required power

4.Light in weight, anti corrosion, rust and wear resistant

5. Simple installation and Minimal maintenance requirements

6. Low operating cost and long working life

7. Reliable running with minimal operator attention

8. Strong adaptability to fluctuation of feeding amount, density, size and grade

9. The surface of corundum forms strong friction the concentration effect surpass plastic surface

Application of gravity separator machine spiral chute for chrome separation plant :

Spiral chute concentrator is widely used to the separation for mineral particles, the size of which ranges from 0.3 to 0.02 mm. it can be suitable for dealing with different kinds of ores, such as below:

-Rutile, ilmenite and zircon concentration.

- Iron ore, chromite and manganese beneficiation.

-Tin, tantalum and ore concentration.

-Gold, native copper and base metal recovery.

-Silica sands processing.

-Titano-magnetite concentration.

Spiral chute concentrator is widely used to the separation for mineral particles, the size of which ranges from 0.3 to 0.02 mm. it can be suitable for dealing with different kinds of ores, such as below:

-Rutile, ilmenite and zircon concentration.

- Iron ore, chromite and manganese beneficiation.

-Tin, tantalum and ore concentration.

-Gold, native copper and base metal recovery.

-Silica sands processing.

-Titano-magnetite concentration.

Inner surface without riffiles/grooves

For Separate the Fine particles and Slurry ore.

For Separate the Fine particles and Slurry ore.

Inner surface with riffles/grooves

is to separator the ore with Coarse particles

is to separator the ore with Coarse particles

Spiral Chute Data

|

Model

|

5LL-2000

|

5LL-1500

|

5LL-1200

|

5LL-900

|

5LL-600

|

5LL-400

|

|

Outside dia (mm)

|

2000

|

1500

|

1200

|

900

|

600

|

400

|

|

pitch (mm)

|

1200

|

540, 720

|

900, 720, 540

|

675, 540, 405

|

450, 360, 270

|

240, 180

|

|

Pitch Dia Ratio

|

0.6

|

0.75, 0.6, 0.45

|

0.75, 0.6, 0.45

|

0.75, 0.6, 0.45

|

0.75, 0.6, 0.45

|

0.6, 0.45

|

|

Lateral slope

|

9°

|

9°

|

9°

|

9°

|

9°

|

9°

|

|

Maximum starts per column

|

2

|

4-2

|

4-2

|

4-2

|

2

|

2

|

|

Feeding Size (mm)

|

2-0.04

|

0.3-0.02

|

0.3-0.03

|

0.3-0.03

|

0.2-0.02

|

0.2-0.02

|

|

Feeding Density(%)

|

30-55

|

25-55

|

25-55

|

25-55

|

25-55

|

25-55

|

|

Capacity (T/H)

|

7-10

|

6-8

|

4-6

|

2-3

|

0.8-1.2

|

0.15-0.2

|

|

Size

|

Length (mm)

|

2120

|

1560

|

1360

|

1060

|

700

|

|

|

Width (mm)

|

2120

|

1560

|

1360

|

1060

|

700

|

|

|

Height (mm)

|

5600

|

5230

|

5230

|

4000

|

2600

|

|

Weight (Kg)

|

1200

|

800

|

600

|

400

|

150

|

50

|

Successful cases

Spiral Chute Application in Tanzania for ilmenite

capacity:100TPH

Mineral:ilmenite

feeding size:3mm

site:Tanzania

machines:hopper,spiral chute,shaking table ,pumps and etc

JXSC Chief Engineer Mr. Lee services at customer's ilmenite ore site to guide for installation, commissioning, start up and

training.

capacity:100TPH

Mineral:ilmenite

feeding size:3mm

site:Tanzania

machines:hopper,spiral chute,shaking table ,pumps and etc

JXSC Chief Engineer Mr. Lee services at customer's ilmenite ore site to guide for installation, commissioning, start up and

training.

50TPH Tin process in Malaysia

capacity:50TPH

Mineral:Tin

feeding size:0-3mm

site:Malaysia

machines:hopper,mixing tank ,spiral chute,pumps and etc

Mineral:Tin

feeding size:0-3mm

site:Malaysia

machines:hopper,mixing tank ,spiral chute,pumps and etc

We have provided the sprial chute for many customers in Sudan,Mali, Mozambique, Nigeria, Suriname, Ghana, South

Africa,Uganda,Zambia, Tanzania, Angola, Canada, Austrialia, Chile, Peru,ect. For Alluvail gold washing plant, coltan ore mining plant,diamond washing plant, Iron ore washing plant,ect.

Africa,Uganda,Zambia, Tanzania, Angola, Canada, Austrialia, Chile, Peru,ect. For Alluvail gold washing plant, coltan ore mining plant,diamond washing plant, Iron ore washing plant,ect.

Packing & Delivery

◆ Ways of packing

1.Small parts packed in the wooden cases

2.Big parts packed by plastic membrane

3.The whole big machine is loaded in the container

3.The whole big machine is loaded in the container

◆ Shiping by sea/air freight

1. Usually our mining machines are shipped in 40'HQ or Flat Containers by sea.

2. Our mining equipments can be also shipped by air if customers request.

2. Our mining equipments can be also shipped by air if customers request.

Company Introduction

◆ Jiangxi walker Machinery Co.,Ltd

Jiangxi walker Machinery Co.,Ltd, are a professional manufacturer of complete set mining equipments, a sub-company of JXSC mine machinery factory in Jiangxi province.professional at providing complete set processing equipments for Gold ore /Tin ore /Tungsten ore /Iron ore / Diamond/ Coltan ore / Silica sand / Zircon sand/ Black sand/Chrome ore, ect. As well as complete set small lab mining machines.

1.Inquiry and consulting support.

2.Ore sample testing support.

3.View our Factory.

4.Design Flowchart.

2.Ore sample testing support.

3.View our Factory.

4.Design Flowchart.

1.Training how to instal the machine, training how to use the machine.

2. 1 year warranty .

3.Engineers available to service machinery overseas.

2. 1 year warranty .

3.Engineers available to service machinery overseas.

FAQ

1.How is the quality of your products?(mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will do a test on every machine before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description or promise we made before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before factory delivery, which is international trade practice; Finished product pictures will be provided to customers before delivery.

If you are interested in our products, please don't hesitate to contact us. Could you tell me the following questions, so that I can give you a complete solution, including best Exw-works Price Quotation!

1. Which machine do you need? like gold washing machine, spiral chute, vibrating screen, Jig separator, Shaking table, etc.

2. What is your raw ore that you plan to process? like gold ore, diamond ore, tantalite or silica sand, etc.

3. What is the capacity you need? Like 10 tones per hour.

4. What is the feeding size to the machine? and what is the discharging-material size that you require?

Sincerely welcome to send your inquiry,you can get best quotation and professional service.

Answer: Our products are manufactured strictly according to national and international standard, and we will do a test on every machine before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description or promise we made before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before factory delivery, which is international trade practice; Finished product pictures will be provided to customers before delivery.

If you are interested in our products, please don't hesitate to contact us. Could you tell me the following questions, so that I can give you a complete solution, including best Exw-works Price Quotation!

1. Which machine do you need? like gold washing machine, spiral chute, vibrating screen, Jig separator, Shaking table, etc.

2. What is your raw ore that you plan to process? like gold ore, diamond ore, tantalite or silica sand, etc.

3. What is the capacity you need? Like 10 tones per hour.

4. What is the feeding size to the machine? and what is the discharging-material size that you require?

Sincerely welcome to send your inquiry,you can get best quotation and professional service.

Hot Searches