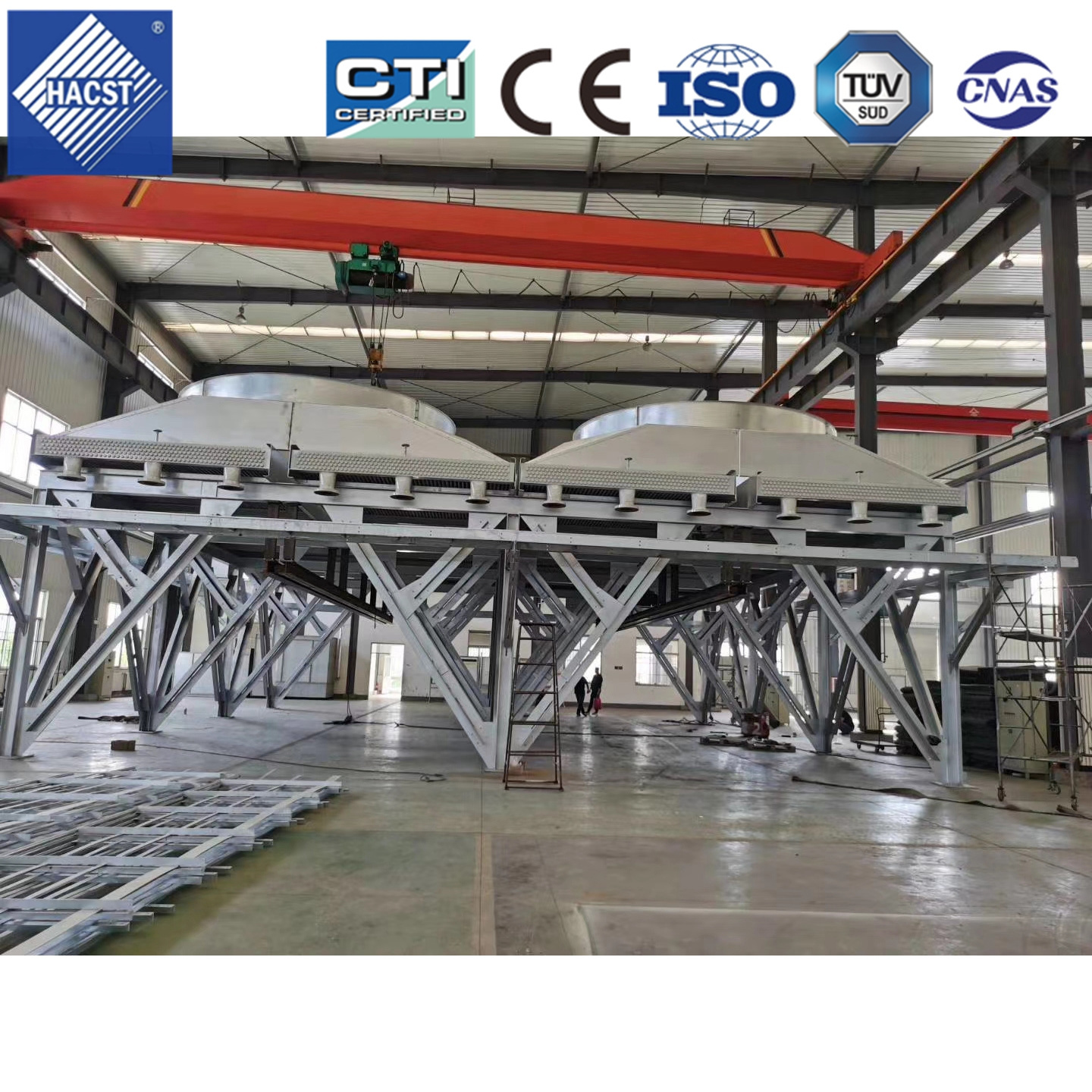

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

0.55-60kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HACST

-

Weight:

-

1900 KG

-

Color:

-

Customer's Request

-

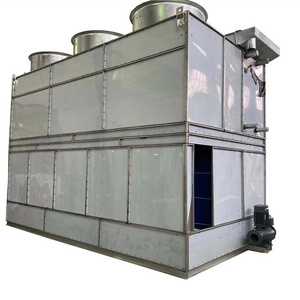

Shape:

-

Bottle

-

Fan Type:

-

Axial Flow Fan

-

Function:

-

Water Chileer Cooling Tower

-

Application Fields:

-

Industial

-

Size:

-

Customer Size Accepted

-

After-sales Service Provided:

-

Engineers

-

Cooling Capacity:

-

200T

Quick Details

-

Cooling Type:

-

Counter Flow

-

Material:

-

Metal

-

Voltage:

-

220V, 280V, 380V, 440V and others

-

Power:

-

0.55-60kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HACST

-

Weight:

-

1900 KG

-

Color:

-

Customer's Request

-

Shape:

-

Bottle

-

Fan Type:

-

Axial Flow Fan

-

Function:

-

Water Chileer Cooling Tower

-

Application Fields:

-

Industial

-

Size:

-

Customer Size Accepted

-

After-sales Service Provided:

-

Engineers

-

Cooling Capacity:

-

200T

The difference between counter flow cooling tower and cross flow cooling tower, help you to choose the suitable tower:

1. Efficiency.

For counter flow cooling tower, water and air in opposite contact, resulting in high heat exchange efficiency.

About cross flow cooling tower, for the same amount of water and the same type of filler, the required filler volume will be larger.

2. Tower height.

Supposing that same foot print, due to factors such as the height of the air inlet and the horizontal arrangement of the water eliminator, the total height of the counter flow tower is higher and the volume is larger.

Since the filler height is close to the tower height and the water collector does not occupy the height, the total height of the cross flow tower is lower and the volume is smaller.

3. Noise.

There is a large distance between the counter flow tower filler and the lower water tank. When water falls from the filler, it will produce a beeping sound and a loud noise.

A small part of the lower part of the cross flow tower packing is submerged in the water, so that after the water flows through the packing surface, it falls directly into the lower water tank and the noise is very low.

4. Water loss.

Since the fan of the counter flow cooling tower is located directly above the filler and is relatively close to it, the amount of floating water is large. In addition, the splash loss of water in the lower tank is very large, and it is easy to form water mist in the cooling circle, which can easily cause the reproduction of Legionnaires' flora.

The cross flow tower fan is located in the center of the cooling tower, and the fillers are located on both sides, so the amount of floating water is very small, making it an environmentally friendly products

5. Water distribution system.

Counter flow cooling tower uses nozzles to distribute water, which requires high pressure heads and the nozzles are easily clogged.

The cross flow tower adopts a water distribution system that naturally falls due to gravity. The water distribution holes are not easily blocked and the water is distributed evenly, which maximizes the filler performance.

6. Power consumption.

The water and the air stream in the counter flow cooling tower flows in the opposite direction, and the water distribution blocks the air stream, so the wind resistance is high and the motor consumes much more of the power.

The height of cross flow cooling tower is lower than the counter flow cooling tower. The hight of the air inlet almost equals the hight of the fills, so the inlet air speed is lower and the motor consumes less power.

7. Maintenance.

The entire body of the counter flow tower is a closed structure, and must be shut down during equipment inspection or routine maintenance.

The cross flow cooling tower is equipped with an access door, and there is an inspection space inside the tower, so that the equipment can be inspected and maintained without shutting down.

1 Q: Is your company a manufacture or a trading company?

A: We are a leading cooling tower manufacturer and trading combo with more than 40 years producing experience since 1975.

The famous brand-"Heng An" is well known not only China but all over the world.

As a group company loacted in Weifang Citey of China, we have more than 1000 employees, area of 34hectares and total assets of USD 160 million.

2 Q: What is the difference between a "counter flow" and a "cross flow" cooling tower?

A: The cross flow or counter flow designation characterizes the orientation of the airflow within the heat-transer medium (fill) in the tower with respect to the direction of water flow. In counter flow towers air travels vertically upwards through the fill and makes intimate contact with water droplets falling down through the fill. Hence the air and water travel in opposite directions.

In cross flow cooling tower, the air passes through the fill medium in a horizontal direction, thus crossing the downward water flow.

At same situation, counter flow tower are inherently more efficient than cross flow tower.

3 Q: How do you get repair parts and how long does it take?

A: We have workshop and backup store supplying all parts. 90% of spare parts can be distributed to any plae on the world within one week.

4 Q: What if you don't have the professional engineers to install or maintain the tower?

A: We could dispatch experienced engineer on site to install the towers and train your staff for tower operation and maintaince.

5 Q: How can I choose a suitable cooling tower?

A: If you are available to provide the following information, we can help you to choose the suitable cooling tower.

| Application | Which industry or system using for? For example, HAVC system, casting cooling system |

| Water flow capacity | How many tons of water treatment per hour? |

| Inlet water temp. | Tempreture of hot water to be cooled |

| Outlet water temp. | Tempreture of cooled water, usually it would be at least 3-4 ºC higher than the bulb tempreture. |

| Wet bulb temp. | Highest wet bulb temp. of the location/area or city to install the tower is essential to know to evaluate the size of towers. |

| Power supply | The standard is 380V/3 phases and we have stock. But for customization, the delivery time would be longer. |