- Product Details

- {{item.text}}

Quick Details

-

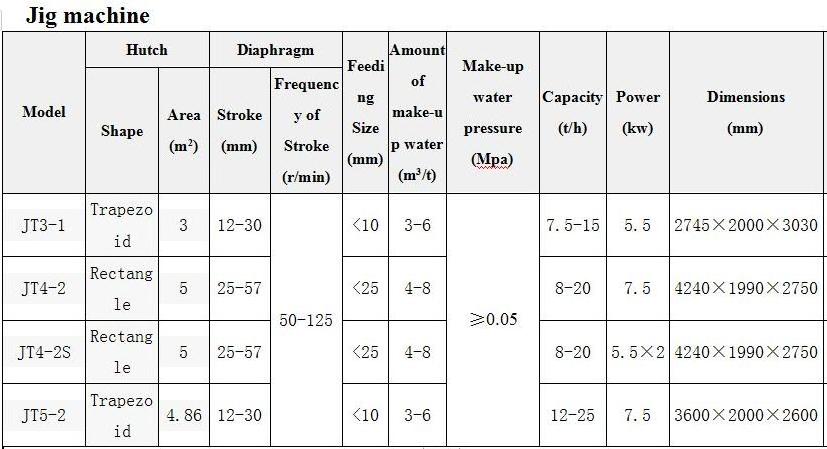

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3600*2000*2600mm

-

Weight:

-

4500KG

-

Warranty:

-

12 Months

-

Keywords:

-

Tin ore beneficiation equipment separation machine jig machine

-

Stroke:

-

12-30mm

-

Frequency of stroke:

-

50-125r/m

-

Feeding size:

-

<10mm

-

Amount of make-up water:

-

3-6 CBM/t

-

Make up water pressure:

-

≥0.05Mpa

-

Capacity:

-

12-25t/h

-

Application:

-

Ore concentration

-

whole line machine:

-

supply

-

Certification:

-

ISO9001:2008

Quick Details

-

Production Capacity:

-

90%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

GANDONG

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3600*2000*2600mm

-

Weight:

-

4500KG

-

Warranty:

-

12 Months

-

Keywords:

-

Tin ore beneficiation equipment separation machine jig machine

-

Stroke:

-

12-30mm

-

Frequency of stroke:

-

50-125r/m

-

Feeding size:

-

<10mm

-

Amount of make-up water:

-

3-6 CBM/t

-

Make up water pressure:

-

≥0.05Mpa

-

Capacity:

-

12-25t/h

-

Application:

-

Ore concentration

-

whole line machine:

-

supply

-

Certification:

-

ISO9001:2008

Tin ore beneficiation equipment separation machine jig machine for Tin/Tantalum-niobium/diamond/gold/tungsten/ilmenite/

Tin ore beneficiation equipment separation machine jig machine for Tin/Tantalum-niobium/diamond/gold/tungsten/ilmenite/

chrome

Product Description

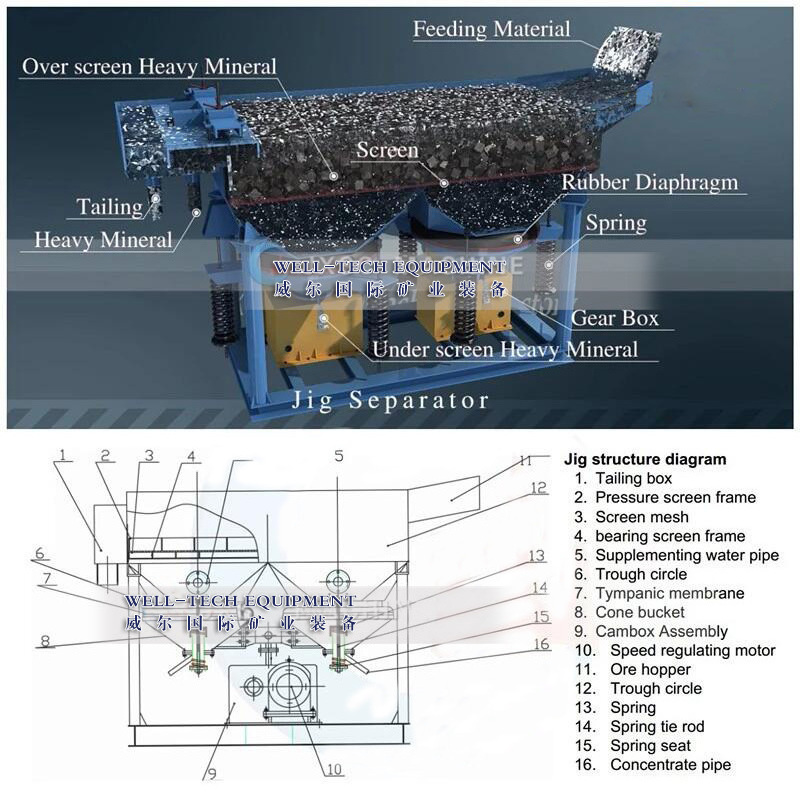

Our Saw-tooth Wave Jig is a new type of energy saving and high efficient gravity separation equipment and developed based on the traditional sine wave jig.

The difference between saw-tooth wave jig and sine wave jig is that the pulsation curve for jigging is saw-tooth wave shape, with speedy upward flow and slow downward flow.

Bed layer is elevated integrally and slowly dropped with a long effective loose time, allowing significant increase of handling capacity for unit screen surface, decrease of lower limit of grain size recovery and large save of make-up water for under-size fraction.

Main Features:

1. High capacity

2. High concentration ratio and high recovery

3. Fabricated with highest quality material

4. Easy to install, operate and maintain

5. The pulsation curve is saw-tooth wave shape facilitate heavy mineral to settling

6. Saving water 30-40% than ordinary jig

7. The pulsation speed very easy adjusted by regulator

8. Suitable for roughing and desliming

9. Can achieve a good result in processing such as placer gold, tungsten, iron, tin,

hematite, cope, tantalum-niobium, titanium, manganese, barite, zirconium, chrome and gemstone etc.

Gold and diamond plant

FAQ:

Q:You are factory or trade company?

A:We are the biggest grav it y separator machine manufacturer in China.we have 6 modem

workshops,1sample test workshop,1office build.

Q:If your company can provide whole line machine?

A:Yes,From crushing or washing to get final gold bar.

Q:What's capacity you can provide?

A:All machine can customization,we can provide from 1t/h-100t/h.

Q:If can arrange engineer come to worksite for installation?

A:Yes.

Mineral processing line case show

Our goal is to provide customers with one stop service in the field of mining, including the minerals in the mineral analysis, mineral processing test, engineering design, equipment production, equipment installation, equipment debugging and of technical training etc integrated services, through the provision of our perfect services to solve all customer's problem from his investment to his return.

Jiangxi Well-tech International Mining Equipment Co.,Ltd. (Gandong Mining Equipment) is a large mineral processing service company specialized in designing, manufacturing, installing and debugging of mining equipment as well as providing flow sheet design and course training of mineral processing.

Our company covers an area of 48,000 square meters, the workshop covers 20,000 square meters, we have various large modernized machinery process facilities, professional engineering team and installation team.

Now our company is the largest manufacturer and exporter of gravity dressing equipment in China. And Our customs are all over the world,so far,we sold 5 coutinents,more than 50 countries.

Pre-Sales Service

Inquiry and consulting support.

Sample testing support.View our Factory.

After-Sales Service

1.

Video technical support

2.

Field installation, commissioning and training

3.

Field maintenance and repair service

4.

Online support

5.

Engineers available to service machinery overseas.