- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SANKIN

-

Model Number:

-

8118A/8118B

-

Type:

-

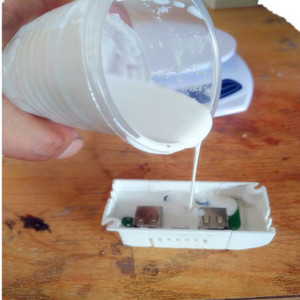

Epoxy Potting Compound Circuit Boards

-

Product name:

-

Epoxy AB Glue

-

Color:

-

transparent colour

-

Shelf life:

-

6 Months

-

Keywords:

-

Epoxy Resin Liquid

-

Package:

-

Customized Package

-

Brand:

-

SANKIN

-

Certificate:

-

MSDS RoHS

-

Feature:

-

High temperature resistance/Impact resistance

-

Proportion:

-

100:20

Quick Details

-

CAS No.:

-

38891-59-7

-

Other Names:

-

Epoxy Resin and Hardener

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SANKIN

-

Model Number:

-

8118A/8118B

-

Type:

-

Epoxy Potting Compound Circuit Boards

-

Product name:

-

Epoxy AB Glue

-

Color:

-

transparent colour

-

Shelf life:

-

6 Months

-

Keywords:

-

Epoxy Resin Liquid

-

Package:

-

Customized Package

-

Brand:

-

SANKIN

-

Certificate:

-

MSDS RoHS

-

Feature:

-

High temperature resistance/Impact resistance

-

Proportion:

-

100:20

Product Description

Features

|

Exterior

|

A

|

black viscous body

|

The mixing ratio

|

A:B=100:20(weight ratio)

|

|

|

B

|

brown liquid

|

The mixing ratio

|

|

|

Viscosity

(40℃,cps)

|

A

|

1900-2400

|

mixed viscosity(40℃,cps)

|

400-600

|

|

Viscosity

|

B

|

15-45

|

|

|

|

Density

((25℃,g/cm³))

|

A

|

1.66±0.02

|

Available time

(25℃,100g)

|

25±5min

|

|

Density

|

B

|

0.98±0.02

|

|

|

|

shelf life (25℃)

|

A

|

180days

|

Curing conditions

|

25℃×24h or 60℃×1.5h

|

|

|

B

|

180days

|

|

|

Cured material properties

|

Hardness (60℃×1.5hrs)

|

shoreD

|

≥80

|

|

Impact strength

|

Kg/mm²

|

5~7

|

|

Volume resistivity

|

Ω·cm

|

≥10

14

|

|

Dielectric strength

|

Kv/mm

|

≥15

|

Precautions

1. When material A is stored for a long time, the filler may precipitate. Stir it thoroughly before use to make the filler disperse evenly before use. When the weather is cold, A The material may become thicker, so you can preheat it to 60°C for 2 hours before use.

2. When mixing, please follow the prescribed mixing ratio, weigh accurately, and use up materials A and B as soon as possible after mixing. If the mixture is left aside for too long, it will affect the use process and product quality.

3. Try to use a round barrel for the mixing container. The barrel wall should be smooth. During the mixing process, the barrel wall and bottom should be scraped to ensure uniform mixing.

4. The usable time after mixing A and B has a great relationship with the temperature and mixing amount after mixing. The higher the temperature, the greater the mixing amount, and the shorter the usable time. Therefore, the mixing temperature and mixing amount should be determined according to the on-site operation. Sure.

5. Before filling, the components need to be preheated and dehumidified at 100~110°C for more than 2 hours. If conditions permit, filling the glue in a vacuum state (vacuum degree reaches -0.1MPa) will have better permeability; the higher the vacuum degree, the better. , the longer the pressure holding time, the better the permeability.

6. This product is safe and non-toxic after curing, but the uncured epoxy resin and curing agent are irritating to the human body to varying degrees, so try to avoid direct contact with the human body. If contact with the curing agent causes skin allergies, soak it in a 1% acetic acid dilute solution for 15-30 minutes to neutralize the curing agent amine. If necessary, ask a doctor for examination and treatment; if it accidentally splashes into your eyes, wash it with plenty of water for 15 minutes. For the above, please ask a doctor for examination and treatment if necessary.

7. When cleaning, it is best to use acetone or alcohol first, and then clean it with soap and water.

The above performance data are only for reference when used by customers, and do not guarantee all the data that can be achieved in a specific environment. Customers are kindly requested to refer to the actual data when using.

Hot Searches