- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Aoqiang

-

Model Number:

-

ZDF-450

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

8300*2750*1800 mm

-

Weight:

-

7000 KG

-

Name:

-

Kraft Paper Square Bottom Bag Making Machine With Flexo Printing Uni

-

Bag width:

-

260-450 mm

-

Bottom Size:

-

85-180 mm

-

Cutting Length:

-

270-530 mm

-

Bag Length:

-

210-450mm

-

Max. Speed:

-

180 pcs/min

-

Paper Roll Width:

-

700-1250 mm

-

Max. reel weight:

-

800 KG

-

Max.Roll Diametr:

-

1200 mm

-

Paper specification:

-

80-180 gsm

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Shopping Bag

-

Material:

-

Paper

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Aoqiang

-

Model Number:

-

ZDF-450

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

8300*2750*1800 mm

-

Weight:

-

7000 KG

-

Name:

-

Kraft Paper Square Bottom Bag Making Machine With Flexo Printing Uni

-

Bag width:

-

260-450 mm

-

Bottom Size:

-

85-180 mm

-

Cutting Length:

-

270-530 mm

-

Bag Length:

-

210-450mm

-

Max. Speed:

-

180 pcs/min

-

Paper Roll Width:

-

700-1250 mm

-

Max. reel weight:

-

800 KG

-

Max.Roll Diametr:

-

1200 mm

-

Paper specification:

-

80-180 gsm

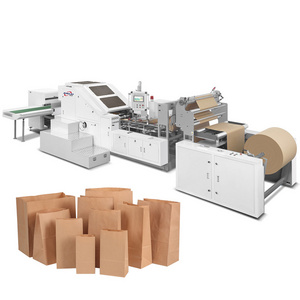

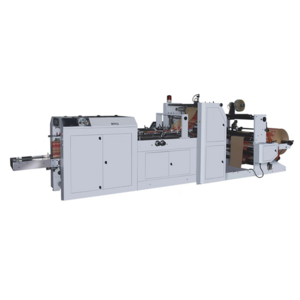

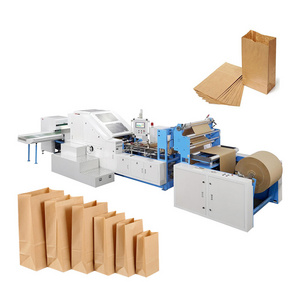

Fully Automatic Brown Kraft Paper Bag Making Machine

Introduction :

Roll Feeding square bottom paper bag making machine forming the paper bag in one process from printed or unprinted roll paper , side gluing, roll folding, roll paper cutting, bottom folding, bottom gluing, bottom forming, bag formation at a stroke. This machine controls by PC programmable servo motor through the human-machine touch screen interface. It can produce various of specifications paper bags. This machine have advantages of high speed, quickly replace the paper bag specifications, more wide range adjusting etc. It is an ideal machine for producing food bag, shopping handles bag.

Main Parameters

|

Model |

ZDF-450 |

|

Paper Weight |

80-180 gsm |

|

Bag Length |

L=C- (H ÷ 2 + 15~25) |

|

Bag Width |

260-450 mm |

|

Width of Paper Bag Bottom |

85-180 mm |

|

Max width of paper roll |

700-1250 mm |

|

Max. Diameter of Paper Roll |

1200mm |

|

Normal Speed |

180pcs/min |

|

Internal Diameter of Roll Core |

76mm

|

|

Power Voltage |

380v,50/60 HZ, 3 phases |

|

Power |

12KW

|

|

Weight |

3500kg |

|

Size |

6600*1400*1500 mm |

pictures:

Machine scene pictures

Main Features

1. The human-machine touch screen interface, the work condition can be shown in real- time.

2. Equipped with accurate servo motor drive, it makes the machine run steadily and efficiently.

3.Pneumatic paper reel lifting device make paper reel changing easy.

4. automatic constant tension control system. The tension will be just right from beginning to end.

5. Double photoelectric sensor limit automatic correction control system and deviation rectification stability, energy saving, long life.

6. Rotary serrated cutter (or flat-blade cutter) with elliptical gears is used for cutting , Thumb buttons, appressed bottom cutting device, bag type have many choices.

7. Don't stop machine side clamp, CAM synchronous adjustment of structure, the adjustment will become more intuitive, more simple, more time saving.

8. Glue roller air defense coating control, avoid gluing on besmear brush e s hub surface directly, reduce unnecessary trouble.

9. Accurate colors tracking system, replace the paper roll, downtime, blackouts, without human intervention, the machine will automatically positioning operation , color errors automatically shut down.

10.

Automatic lubricating oil supply system.

Packaging & Shipping

We have Alibaba.com Trade Assurance

A free service to creat trust between you and us

1. Know who you're dealing with

2. Enjoy comprehensive protection 100% product quality protection, 100% on-time shipment protection,100% payment protection for your covered amount

3. Rate and influence your suppliers

FAQ

Q1: How to visit our Factory? (not a trade company)

A: Option 1: Guangzhou Airport→ Wenzhou Airport→ Pick you up Option 2: Shanghai Airport→ Wenzhou Airport or Rui’an Train Station→Pick you up

Q2: How does your factory do the quality control?

A:“QUALITY FIRST " We purchase qualified parts, test the machine every step when manufacturing.

Q3: How about the installation?

A: Option 1, our engineer install the machines for you, also train your staff until they can run the machine independently. Option 2, you learn installation in our factory.

Q4:Do you have after-sale service?

A: 1 Year Warranty and timeless maintenance service.

Q5: How about the payment term?

A: Payment term:1, T/T 30% , 70% before shipping. 2, Ali Secure Payment.