- Product Details

- {{item.text}}

Quick Details

-

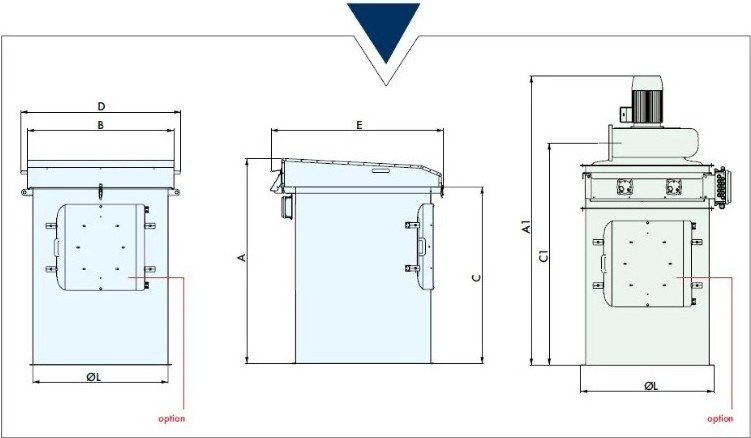

Dimension(L*W*H):

-

800*1500

-

Weight:

-

150kgs

-

Product name:

-

cement silo cleaning machine

-

Material:

-

Carbon Steel

-

Filter Area:

-

14-25m2

-

Motor:

-

3 HP

-

Function:

-

Removing Dust Particles

-

Dust collection type:

-

Vibrating

-

Power:

-

2.2kw

-

Color:

-

Customers' Requirements

-

Certification:

-

CE ISO certificate

Quick Details

-

Minimum Particle Size:

-

0.2micron

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Sino

-

Dimension(L*W*H):

-

800*1500

-

Weight:

-

150kgs

-

Product name:

-

cement silo cleaning machine

-

Material:

-

Carbon Steel

-

Filter Area:

-

14-25m2

-

Motor:

-

3 HP

-

Function:

-

Removing Dust Particles

-

Dust collection type:

-

Vibrating

-

Power:

-

2.2kw

-

Color:

-

Customers' Requirements

-

Certification:

-

CE ISO certificate

SILO DUST COLLECTOR

The Silo filter is a kind of single dust removal equipment with automatic cleaning structure. The Silo filter is widely used in industrial and mining enterprises such as cement, mineral powder, mining, metallurgy, building materials, machinery, chemical industry and grain processing. A small, non-fibrous dry dust or a dust removal device that recycles dry powder in the process. The dust removal efficiency of the roof dust collector is as high as 99%

The dust-containing gas enters the dust collector box through the air inlet, and the fine dust particles are hindered to the outer wall of the cloth bag due to various effects of the cloth bag. The purified gas is discharged through the air outlet of the box on the bag. As the use time increases, the dust adsorbed on the surface of the bag increases, and the gas permeability of the bag is weakened, so that the resistance of the dust collector is continuously increased. In order to ensure that the resistance of the dust collector is controlled within a limited range, a signal is sent from the pulse controller to sequentially open the electromagnetic pulse valve, so that the compressed air in the air bag is sprayed from the nozzle holes of the air injection pipe to the corresponding venturi (referred to as One wind), and when the high-speed airflow passes through the venturi, it induces several times the ambient air of the primary wind (called the secondary air) to enter the filter cartridge, causing a sharp expansion between the bags, which quickly disappears due to the impact of the reverse pulse airflow. The bag is sharply contracted again, so that the dust accumulated on the outer wall of the bag is removed, and the fallen dust enters the ash store.

2. Pack in carton box

3. Pack in wood box

Each item has a minimum order quantity, which would be stated in our quote sheet.

2. What's kind of your packaging ?

Wrapped moisture-proof film on products then packed in wooden cases, or according customer's requirements.

3. Could you give installation and commissioning overseas? How long will it take?

Yes, we supply overseas service, but customers need to pay for the engineers flight tickets, and hotel, food., etc.

Small machines usually takes 15 days, while large machines usually takes about 25 to 30 days.

4. How long is your Delivery Lead Time ?

If there is stock, we can arrange goods at once after we get the payment .If need to be produced, 5-7 working days after receiving payment .

5. What is your machine quality quarantee?