- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customer's Requirement

-

Power:

-

10 Kw-100 Kw

-

Dimension(L*W*H):

-

14000M*8000M*7000M(10 ton /day)

-

Weight:

-

10000 kg

-

heating temperature:

-

420-430degree

-

Heating method:

-

Electromagnetic Heating or by burner

-

Raw material:

-

industrial used Oil

-

Function:

-

Recycle used-oil to clean diesel

-

Final product:

-

Diesel oil

-

Recycling rate:

-

85%-90%

-

Sulfer content:

-

0.151

-

Flash Point (closed cup):

-

60℃

-

Density:

-

0.84kg/L

-

Certificate:

-

ISO CE

Quick Details

-

Flow:

-

1- 100 Tons/Day

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

YANGJIANG Machine

-

Voltage:

-

Customer's Requirement

-

Power:

-

10 Kw-100 Kw

-

Dimension(L*W*H):

-

14000M*8000M*7000M(10 ton /day)

-

Weight:

-

10000 kg

-

heating temperature:

-

420-430degree

-

Heating method:

-

Electromagnetic Heating or by burner

-

Raw material:

-

industrial used Oil

-

Function:

-

Recycle used-oil to clean diesel

-

Final product:

-

Diesel oil

-

Recycling rate:

-

85%-90%

-

Sulfer content:

-

0.151

-

Flash Point (closed cup):

-

60℃

-

Density:

-

0.84kg/L

-

Certificate:

-

ISO CE

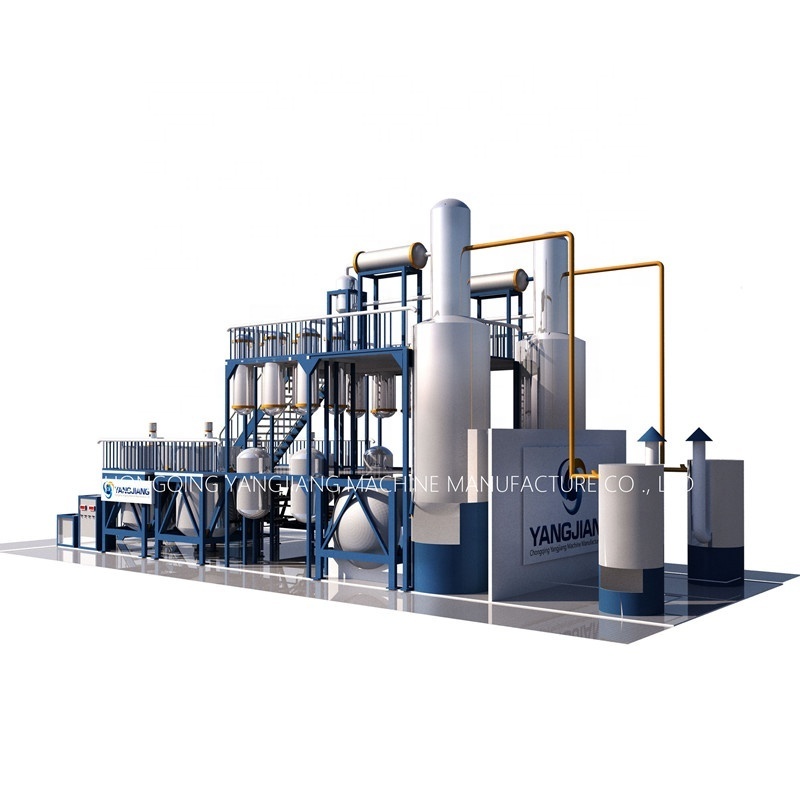

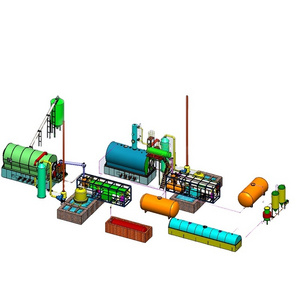

Black waste engine oil to yellow Diesel oil recycling machine

YJ-DSL series is suitable for used engine oil, motor oil, ,machine oi, heavy oil, bunker oil, oil sludge, mineral oil and all kinds of lubricating oil to diesel. After our machine's recycling, the waste oil can be changed into clean diesel oil.

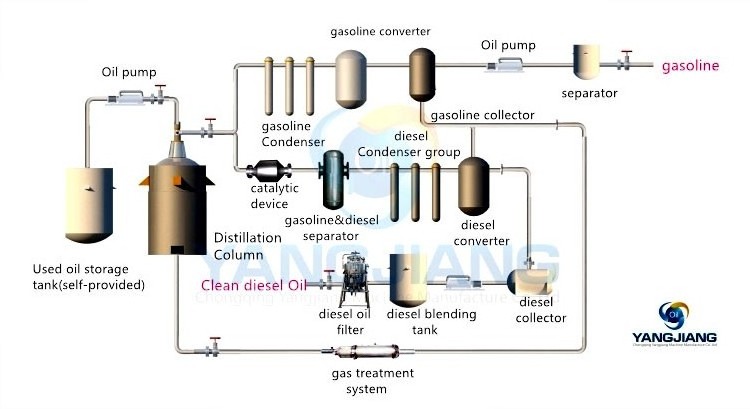

Working Process

The working process is first to pump the waste oil into the distillation kettle, then the heating system will start to heat waste oil. Gasoline components and water in the used oil can be distilled out when the temperature reaches to 50 ℃-100℃. When the temperature reaches to 160 ℃-260℃, after efficient catalyzing and cracking, the light and heavy components in waste oil will convert to diesel. Finally, we filter all collected diesel oil, then we can get finished high-quality diesel oil.

Cracking Process

The feature of our cracking process is very safe, because the temperature setting is rigorous and the machines is stable. Our engineers are committed to design the most reasonable and high efficient distillation and cracking system to maximize the benefits of customers.

Features

1)High recovery rate

the highest recovery rate can reach 92-95%. gasoline 2-5%, diesel oil 85-90%.

2)Easy operation

The YJ-DSL series machine is easy to operate, it needs only 1-3 workers to operate.

3)Rich raw material

YJ-DSL series can recycle all kinds of used black diesel, used engine oil, used machine oil, used mineral oil and almost all industrial oil to diesel oil.

4)Efficient catalyst

It is normal, safe and available.In addition, it helps to ensure a higher recovery rate, and better quality of finished oil.

Application

|

Machine Parameter |

||||||||||

|

Handling capacity |

Ton/day |

0.5 |

2 |

4 |

5 |

10 |

20 |

30 |

50 |

80 |

|

Recovery rate |

% |

<=93 |

||||||||

|

Temperature |

≤ 430 |

|||||||||

|

Working Noise |

dB (A) |

45 |

60 |

65 |

65 |

65 |

70 |

70 |

75 |

75 |

|

Total power |

KW |

10 |

15 |

20 |

22 |

55 |

90 |

130 |

170 |

210 |

|

Dimension MM |

L |

5000 |

8000 |

11000 |

12000 |

14000 |

25000 |

30000 |

60000 |

80000 |

|

W |

3500 |

4000 |

4500 |

5000 |

8000 |

8000 |

10000 |

16000 |

20000 |

|

|

H |

6000 |

7000 |

7000 |

7000 |

7000 |

8000 |

8000 |

8000 |

8000 |

|

| Pyrolysis Diesel Oil Parameter | ||||

| Item | Test standard | Result | Standard value | |

| Density(15℃) | ASTM D1298 | 0.84 kg/l | ---- kg/l | |

| Kinematic viscosity(40℃) | ASTM D445 | 3.36 cst | 1.6-5.8 cst | |

| Flash point(closed cup) | ASTM D93 | 60 ℃ | ≥55 ℃ | |

| Pour point | ASTM D97 | -19 ℃ | ≤ 0 ℃ | |

| Distillation temperature | 10% Point | ASTM D86 | 204 ℃ | --- |

| 50%point | 289 ℃ | ≤300 ℃ | ||

| 90%point | 344 ℃ | ≤355 ℃ | ||

| 95% point | 359 ℃ | ≤365 ℃ | ||

| Cetane index | ASTM D976 | 54.42 | ≥45 | |

| Water content | ASTM D95 | Trace%vol | ≤Trace %vol | |

| Sulfur content | ASTM D1226 | 0.151%wt | ≤0.2 %wt | |