- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

34 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BEIERMAN

-

Voltage:

-

220/380/415/440/480V

-

Dimension(L*W*H):

-

30m*4m*4m

-

Weight:

-

15000 KG

-

Automatic Grade:

-

automatic/semi-automatic

-

Product type:

-

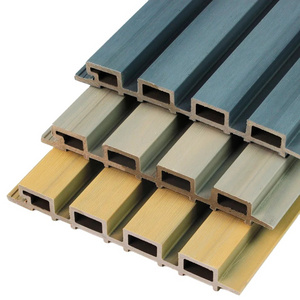

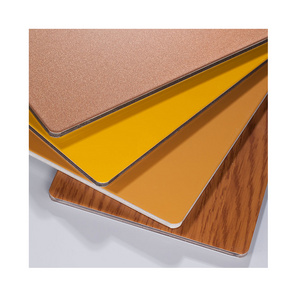

PVC ceiling,wall panel,floor deck,etc.

-

forming method:

-

vacuum forming, water cooling

-

products range:

-

hollow ceiling/wall panel/windowsill

-

extruder type:

-

Conical twin screw extruder

-

After Warranty Service:

-

Video technical support

-

Extruder:

-

SJSZ 55/110 or 65/132

-

inverter:

-

ABB/Delta/LS

-

Temperature controller:

-

OMRON/RKC/FUJI

-

final product:

-

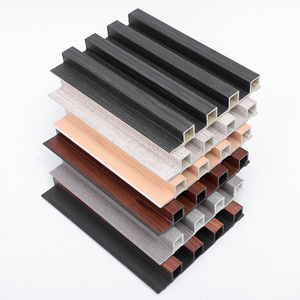

trunking,wall panel,decorated profile

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

Unapplicable

-

Screw diameter (mm):

-

65/132

-

Screw Speed (rpm):

-

34 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BEIERMAN

-

Voltage:

-

220/380/415/440/480V

-

Dimension(L*W*H):

-

30m*4m*4m

-

Weight:

-

15000 KG

-

Automatic Grade:

-

automatic/semi-automatic

-

Product type:

-

PVC ceiling,wall panel,floor deck,etc.

-

forming method:

-

vacuum forming, water cooling

-

products range:

-

hollow ceiling/wall panel/windowsill

-

extruder type:

-

Conical twin screw extruder

-

After Warranty Service:

-

Video technical support

-

Extruder:

-

SJSZ 55/110 or 65/132

-

inverter:

-

ABB/Delta/LS

-

Temperature controller:

-

OMRON/RKC/FUJI

-

final product:

-

trunking,wall panel,decorated profile

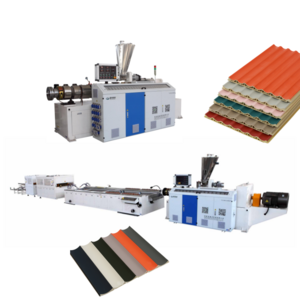

PVC electric cable protection trunking profile extrusion line specially designed for the PVC powder, PVC pellets extruding to profiles, trunks.

there are many different sizes trunking, such as

12*12,15*10,16*16,20*10,25*16,25*25,40*16,40*25,40*40,60*40 two cavity;

60*60,80*40,80*60,100*40,100*60 single cavity.

accurate mould will be according to buyer's drawing or sample.

here take one of our PVC trunking profile extrusion line as below for your reference,

small size product can settle two outlets, big size product can settle single outlet.

|

No.

|

Major parts

|

Detail information

|

|

1

|

DTC-600 Screw conveyor

|

Driving motor:1.5KW

|

|

2

|

SRL-Z200/500 PVC powder Mixing unit

|

Driving motor:45/7.5 KW, Capacity: 350KG/hour

|

|

3

|

DTC-600 screw conveyor

|

Driving motor:1.5KW

|

|

4

|

SJSZ-55/110 Conical twin screw extruder

(or SJSZ-65/132 Conical twin screw extruder)

|

55/110 model's Driving motor:30KW,capacity:90-160kg/h

|

|

5

|

PVC trunking mould

|

12*12,15*10,16*16,20*10,25*16,25*25,

40*16,40*25,40*40,60*40 two cavity;

60*60,80*40,80*60,100*40,100*60 single cavity.

|

|

6

|

Vacuum forming table

|

Tank length: 4000mm*1100mm; vacuum pump: 5.5KW*2pcs,

Water pump: 1.5 KW, 1pc;4KW,1pc. stainless steel tank |

|

7

|

Profile haul off machine

|

Haul off motor: 0.75KW*2, 2 claws ;rubber bricks

|

|

8

|

Profile Cutting machine

|

2.2 KW , knife lift cutter.

|

|

9

|

Profile Stacker

|

Stacker Length: 4meter, automatic control

|

The following parts are optional up to you.

|

No.

|

Major parts

|

Detail information

|

|

1

|

Crusher

|

to crush those waste material after producing profile.

|

|

2

|

Pulverizer

|

to pulverize those crushed flakes to powder, then recycle to extrude profile.

|

|

3

|

Chiller or Cooling Tower

|

to cool the recycled water in the forming table,to cool product

|

Advantage:

- world famous brands major parts:

-- Skilled workers for machines producing

--- Experience engineers all with passports ready for customers services

----Good Prices get from square quantity major parts purchase with lower cost

----- Full line running test for customer checking before delivery

|

Motor

|

SIEMENS, DAZHONG

|

|

Inverter

|

ABB/FUJI/LG

|

|

Contactor

|

SIEMENS/Schneider

|

|

Temperature controller

|

OMRON/RKC

|

|

PLC system

|

SIEMENS/DELTA

|

- Zhangjiagang Beierman Machinery Co.,Ltd. is a modern factory, which engaged in the plastic extrusion machines and recycling machines' researching,manufacturing and sales.

-Our professional research teams,sales teams,rich experience and processing equipment will offer customers high quality machines and perfect after sales services.

-High quality,Quick services,Mutually beneficial principle will be our promise to customers around the world.

Ribbon mixer, low speed mixer~~~for PVC powder;

Hopper dryer mixer~~~for plastic granules;

Color mixer~~~for plastic granules.

2, PC/PMMA/ABS LED light diffuser,bottom tube making line.

3,PVC Supermarket Price tag profile production line; Soft seal production line; Rigid rod production line.

4,Single screw extruder;

5,Conical twin screw extruder;

6, 2layer; 3 layer;4 layer PPR pipe co-extrusion line; PPR, PE, HDPE, PE-RT pipe production line;

7, Corrugated pipe extrusion line (Single wall corrugated; Double wall corrugated);

8, 3 layer PVC pipe co-extrusion line; PVC pipe production line;

9, PVC 2 cavity pipe production line;

10, PVC 4 cavity pipe production line;

11,Pipe belling machine;

12, PVC rain gutter profile line; Trunking/panel profile line;WPC profile production line; and 2 layer PVC profile co-extrusion

line;

13, Granulating line-water ring granulating,or string granulating (PP PE );

14, Granulating line-hot die face granulating (PVC).