- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1.3x0.83x1.11m

-

Weight:

-

200 KG

-

Marketing Type:

-

high capacity

-

item:

-

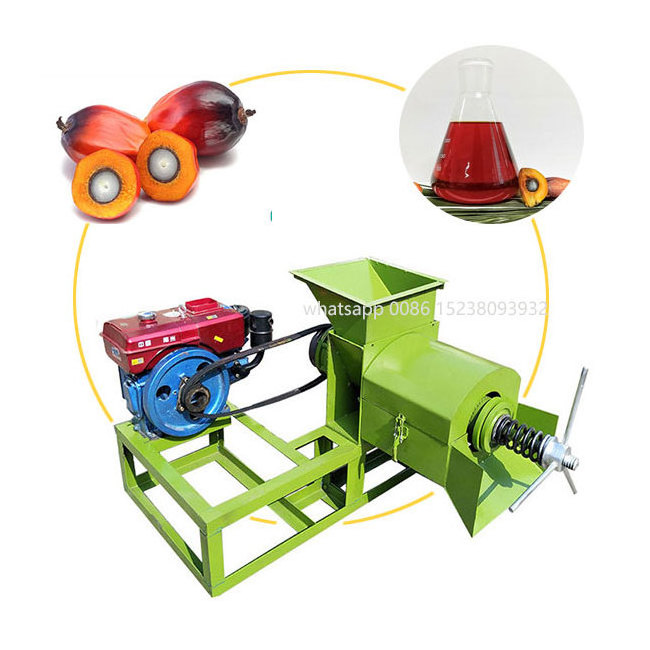

Palm Oil Extraction Equipment

-

application:

-

Palm Fruit

-

Advantage:

-

long service life

-

drive:

-

electric motor or diesel engine

-

Material:

-

Carbon Steel Q235

Quick Details

-

Production Capacity:

-

100-500kg/h, 100-500kg/h

-

Place of Origin:

-

China

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1.3x0.83x1.11m

-

Weight:

-

200 KG

-

Marketing Type:

-

high capacity

-

item:

-

Palm Oil Extraction Equipment

-

application:

-

Palm Fruit

-

Advantage:

-

long service life

-

drive:

-

electric motor or diesel engine

-

Material:

-

Carbon Steel Q235

Palm Oil Press Machine

The price marked on the website is for reference only. There are many product models, please contact Amanda for exact price

We have solution for small shape palm oil press. You need to thresh palm fruit bunch into palm fruit grain, and boil fruit grain. Then you can use oil press machine to get red palm oil or kernel oil.

The process mainly includes the following sections.

Raw material storage section : Fresh palm fruit is measured and recorded by the weighing room into the fresh palm fruit bunches, and the measured palm fruit bunches are unloaded to the fruit loading slope and stored.

Sterilization process : Put the palm fruit bunches into a horizontal sterilizer or a vertical sterilizer and heat for 90-120 minutes.

The purpose of sterilization is to destroy the lipase to prevent the free fatty acid content in the oil from increasing;

High temperature sterilization can make the fruit soft and facilitate mechanical threshing;

Pre-treat the peel to prepare for subsequent processing;

Pre-conditioning the core to reduce the damage of the kernel.

The process of sterilization:

After the palm fruit enters the sterilization tank, close the sterilization tank and close the door, open the exhaust valve under the sterilization tank, and then pass in saturated steam with a pressure of 3bar (temperature about 145°C), and close the tank after the cold air in the tank is basically discharged. The exhaust valve enters the cooking and sterilization stage, and the sterilization time is generally 90 to 120 minutes. After the sterilization is completed, close the steam inlet valve and open the valve to the muffler to drain the water and steam in the tank before opening the door of the sterilization tank.

Threshing section : The purpose of threshing is to separate the oil palm fruit from the fruit bunch through strong vibration. The threshing equipment is a drum threshing machine. The separated oil palm fruit is then sent to the cooking tank through a conveyor. The empty fruit bunches are discharged from the other end of the drum to the storage yard, or are recycled as palm orchard coverings in the delivery area, or burned on site as fertilizer and applied to the farmland.

Pounding and steaming : The purpose of mashing and steaming is to tear the skin of the fruit, separate the pulp from the core and smash the pulp tissue. At the same time, heat the pulp to soften the pulp and destroy the cell structure of the pulp, which is conducive to the precipitation of oil from the pulp tissue. .

The upper part of the mashing tank has an inlet, and the lower part has an outlet. There is a central shaft equipped with many axial beaters in the tank, and the inner wall of the tank is equipped with multiple lining plates. The fruit particles are crushed by the impact of the stirring rods and the collision of the lining plates. The mashing and cooking equipment is a cylindrical tank with a heating jacket. Indirect steam is introduced into the jacket for heating. There is a direct steam nozzle in the tank to adjust the moisture and temperature. Heat for 1h to make the temperature of the whole blank reach about 90℃-95℃. The purpose of heating is to destroy the emulsified state formed by the oil and water in the fruit tissue, reduce the viscosity of the oil, and facilitate the flow and precipitation of the oil.

Squeezing section : After the above steps, the palm fruit is sent to the screw oil press. After the oil palm fruit is pressed, it is divided into: oil, water, a mixture of solid impurities and cake (fiber and core).

Use continuous screw oil press. It has a horizontal box with holes, which is a figure-eight cross, with two screws inside. There is a cake head at the slag discharge port of the box, which can control the pressure to ensure the least residual oil in the cake, and also make Adjust the crushing rate of the core to within a reasonable range. Under the action of the screw pressure, the fat is separated from the pulp tissue and the fried cake is extruded from the machine head, containing the core (not cracked palm kernel oil), and the liquid part flows out from the lower mouth, filtered and sent to the butterfly centrifuge. The crude palm oil is obtained, filtered and then sent to the butterfly centrifuge to obtain the crude palm oil. After being pressed, the oil palm fruit is divided into two parts: a mixture of oil, water, and solid impurities; the oil output rate of fiber and pit is calculated according to the fresh palm fruit bunch, which yields 20% crude palm oil and 2% crude palm kernel oil.

The obtained crude palm oil parameters: orange-red color, semi-liquid oil, surface density (50°C): 0.8896-0.8910, saponification value: (mgkoh/g oil) 190-202, and iodine value (gz2/100g).

|

Model |

ZLGZY300S |

ZLGZY500S |

ZLYY1000D |

ZZYY3000D |

ZZYY5000D |

|

Capacity |

100-200kg/h |

400-600kg/h |

1-2T/H |

3-4T/h |

5-6T/h |

|

Power |

1.5kw/6-8ph |

5.5kw/15ph diesel |

5.5kw |

7.5+1.5kw |

11+2.2kw |

More information for palm oil press

0000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

Service before sale

24 hours online to answer questions that you want to know(Whatsapp, wechat, QQ, Skype, Trade Manager, etc), or you can send email to my email, I will give you a satisfying answer.

Service on sale

1.To provide customers with the new and high quality animal feed pellet machine.

2.Provide pictures that the customer desired about the animal feed pellet machine during production, in the warehouse and before transport.

3.Payment is determined by both parties.

4.Customers to choose the mode of transport.

After-sales services

We offer one year warranty for the whole machine except easy broken parts, Providing the spare parts with favorable price all the time 24 hours online service.