- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Ruding

-

Standards:

-

AAR, UIC, EN, GOST, IRIS, KSR, BS, JIS,TB

-

Process:

-

Forging-machining-heat treatment-machining-inspection-package

-

Certifications:

-

ISO9001, ISO14001, OHSAS18001,TSI, AAR

-

Wheel Diameter:

-

100mm to 1250mm

-

Inspection:

-

Chemical analysis, Metallographic, Mechnical analysis, UT, MT,etc

-

Service:

-

OEM\ODM

-

Wheel type:

-

Single flange/Double flange

-

loading capacity:

-

1-25tons, each one is ok.

Quick Details

-

Material:

-

Iron, Steel, cast steel or cast iron

-

Dimensions (L x W x H) (mm):

-

Customized, As required

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Ruding

-

Standards:

-

AAR, UIC, EN, GOST, IRIS, KSR, BS, JIS,TB

-

Process:

-

Forging-machining-heat treatment-machining-inspection-package

-

Certifications:

-

ISO9001, ISO14001, OHSAS18001,TSI, AAR

-

Wheel Diameter:

-

100mm to 1250mm

-

Inspection:

-

Chemical analysis, Metallographic, Mechnical analysis, UT, MT,etc

-

Service:

-

OEM\ODM

-

Wheel type:

-

Single flange/Double flange

-

loading capacity:

-

1-25tons, each one is ok.

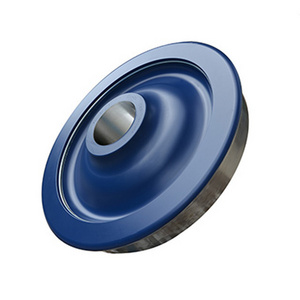

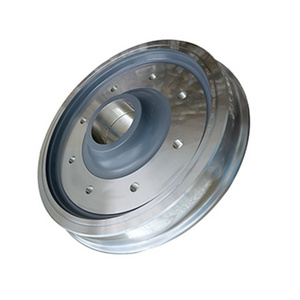

Mining wheels and kiln car wheels are mainly single wheels. The wheels mainly used for various bucket type ore truck, shuttle type ore car, mining flat plate car, side unloading type ore truck, etc.

The main material of Ruding Steel's mining wheels is cast steel, and the wheel axle and end cover are made of 45# steel (equivalent to 1045 steel). We can make core mine cart wheels using two forming methods: casting and forging.

We can customize mine cart wheels as per clients' specifications and requirements.

Specification:

|

Model |

Mine Car Weight kg |

Track mm |

Wheel Diameter |

Max Axle Distance of wheels |

Mindistance of covers |

Axle diameter |

|

ZBL600/300 |

≤2400 |

600 |

300 |

808 |

510 |

60 |

|

ZBL762/300 |

762 |

970 |

672 |

|||

|

ZBL900/300 |

900 |

1108 |

810 |

|||

|

ZBL600/350 |

≤6700 |

600 |

350 |

850 |

490 |

80 |

|

ZBL762/350 |

762 |

1012 |

652 |

|||

|

ZBL900/350 |

900 |

1150 |

790 |

|||

|

ZBL600/400 |

≤9000 |

600 |

400 |

870 |

476 |

95 |

|

ZBL762/400 |

762 |

1032 |

638 |

|||

|

ZBL900/400 |

900 |

1170 |

776 |

Manufacturing process:

1. Steel Melting 2. Round Billet Sawing Cutting 3. Heating 4. Phosphorus 5. Stamping Forming 6. Rolling 7. Bending Punch 8. Hot Stamping 9. Laser Measurement 10. Drop Stack 11. Roughing 12. Hardening 13. Tempering 14. Sampling 15. Pre-processing 16. Finishing 17. The Cold Print 18. Static Equilibrium 19. The Cold Print 20. Hardness Testing 21. Ultrasonic Testing 22. Magnetic

Particle Testing 23. Shot Peening 24. Painting Packaging

1. OEM and customized service.

2. Full machining, primer coating, surface treatment.

3. Complete material testing process.

4. Quality control

If you have any questions, pls feel free to contact us