- Product Details

- {{item.text}}

Quick Details

-

input power:

-

5kw

-

voltage:

-

220V-240V, single phase, 50/60HZ,

-

input current:

-

20.8-22.7A

-

output power:

-

4.2kw

-

output frequency:

-

5-60kHZ

-

cooling system:

-

air cooling

-

machine size:

-

W:242.9mm H:295.2mm D: 504.4mm

-

machine weight:

-

16kg

-

applications:

-

PWHT, welding preheat, joint anti-corrosion coating

-

suitable industry:

-

offshore platform, power station, oil and gas pipeline

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Canroon

-

Weight (KG):

-

70

-

input power:

-

5kw

-

voltage:

-

220V-240V, single phase, 50/60HZ,

-

input current:

-

20.8-22.7A

-

output power:

-

4.2kw

-

output frequency:

-

5-60kHZ

-

cooling system:

-

air cooling

-

machine size:

-

W:242.9mm H:295.2mm D: 504.4mm

-

machine weight:

-

16kg

-

applications:

-

PWHT, welding preheat, joint anti-corrosion coating

-

suitable industry:

-

offshore platform, power station, oil and gas pipeline

5kw induction heating machine/induction heater/induction heating equipment

ATTENTION :

Price is only the machine price,don't include shipping fee,or spare parts like temperature recorder, induction cable, thermocouple, inductors, etc

You can pay directly online, for spare parts,contact me directly!

Brand: Canroon(China manufacturer)

Power :5kw

Frequency :5-60kHZ

Heating temperature : can be high as 788℃

Voltage : single phase, 220-240v, 50/60HZ,

Suitable pipe size : 30-300mm diameter, less than 25mm thickness,

cooling system : air cooling

Thermocouple : 2 PCS

Application industries : offshore platform,power station,oil and gas pipeline construction, etc

Applications : pipe welding preheat, PWHT/ post weld heat treatment, joint anti-corrosion coating, etc

Features : small, portable, digital control, self-fault diagnosis, modular design, fault code feedback, etc

Details of Canroon 5kw induction heating machine/induction heater/induction heating equipment:

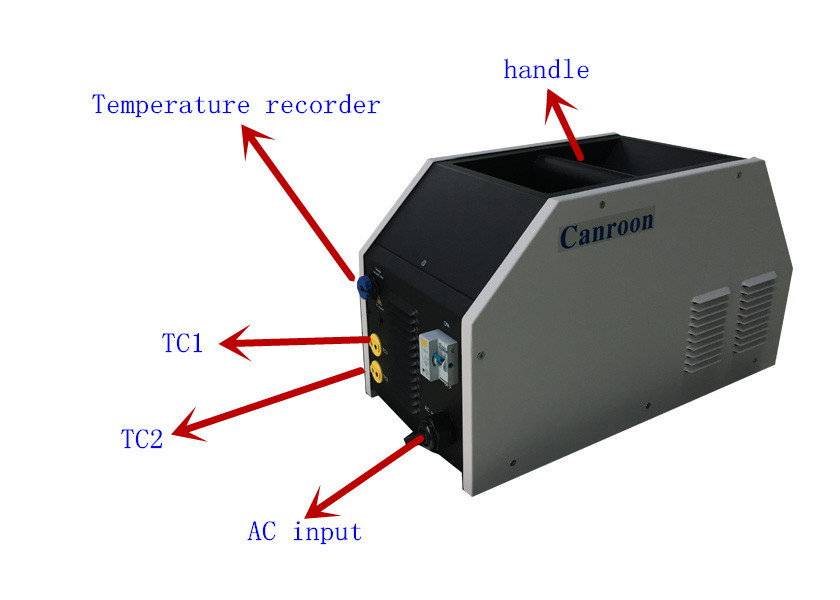

Front side:

Back side:

Technical parameters of 5kw induction heating machine/induction heater/induction heating equipment:

| Model | Temperature | Input Power | Input | Output | Dimension | Weight |

| CR2000-005B-12SF2 | 788℃ | 5kVA |

1-phase 220-240V 50-60Hz 20.8-22.7A |

4.2kW 5-60 KHz duty cycle 100% |

W:242.9mm H:295.2mm D: 504.4mm |

16kg

|

Application details of 5kw induction heating machine/induction heater/induction heating equipment:

Welding preheat:

Suitable for steel pipe, size of 30-300mm outside diameter and less than 25mm thickness, can heat to 120-350℃, heating time is less than one hour accordingly.

PWHT/post weld heat treatment:

Suitable for steel pipe, size of less than 200mm outside diameter, and lesss than 25mm thickness, heating temperature is lower than 788℃.

(temperature recorder will be needed in this part for precise temperature control, and PWHT curve printing, if you need, contact me for details.)

Joint anti-corrosion coating:

suitable for steel pipe preheating before joint anti-corrosion coating, we can provide two different types of inductors: hydraulic type split core inductor, and manual type split core inductor. if you need it, contact me.

Our 5kw induction heating machine/induction heater/induction heating equipment can be connected with following different types of inductors:

C type inductor (usually for pipe welding preheat), blanket type inductor (usually for pipe welding preheat, PWHT), plate type inductor (usually for pipe welding preheat), split core type inductor(manual & hydraulic) (usually for joint anti-corrosion coating). YOU NEED TO PAY FOR THIS.

Accessories of 5kw induction heating machine/induction heater/induction heating equipment:

We offer multiple accessaries like thermocouple, thermocouple welding machine, digital temperature-recorder, remote switchgear, output extension cable, insulation blanket, etc . Complete solution saves your time and ensures you to start work soon after received our dellivery. YOU NEED TO PAY FOR THIS.

- precise control

We have display panel to show working parameters, and temperature recorder can feedback PWHT curve, you can print it.

- Various Control Mode

The interface offers two basic control mode to choose including temperature control and power control . Thus brings the benefit of wide applicability and precise control.

- Fault Record

Fault codes will display and be recorded for reference, and system will respond with protection action like shutdown once fault occurs such as open-loop output or short out.

- Easy Maintenenace

Due to modular design, the maintance will be easy and low-cost.

- Self Diagnosis

Once fault occurs, induction heater will display fault code, which was detailed explained in manual book.

- High Efficiency

This uniquely energy-efficient process converts up to 90% of the expended energy into useful heat, and time-to-temperature is faster than conventional processes, reducing cycle time.

- Uniform Heating

The heat is induced within the part itself by alternating electrical current, thus uniform temperature throughout the heating zone is realized.

5kw induction heating machine/induction heater/induction heating equipment is carefully packed in wooden case for safe delivery by air.