- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

0.9 kg

-

Size:

-

686*54 mm ( dimension for reference)

-

Weight (KG):

-

0.9 kg

-

Length/mm:

-

305±1

-

Component diameter/mm:

-

63±1

-

Effective film area/㎡:

-

0.4

-

Installation:

-

Horizontal/Vertical

-

Permeation mode:

-

External pressure

-

Feed status:

-

Gas

-

Feed temperature/°C:

-

0-80

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

WOBO

-

Material:

-

Wooden box, PP

-

Weight:

-

0.9 kg

-

Size:

-

686*54 mm ( dimension for reference)

-

Weight (KG):

-

0.9 kg

-

Length/mm:

-

305±1

-

Component diameter/mm:

-

63±1

-

Effective film area/㎡:

-

0.4

-

Installation:

-

Horizontal/Vertical

-

Permeation mode:

-

External pressure

-

Feed status:

-

Gas

-

Feed temperature/°C:

-

0-80

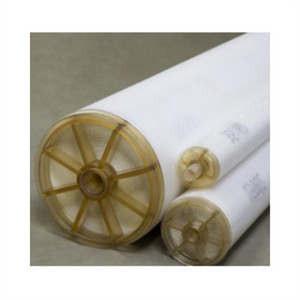

E nvironmentally Friendly Efficient Sulfur Hexafluoride (SF 6 ) Membrane

Professional Acid Resistance Membrane System Efficient 99.9% Sulfur Hexafluoride Membrane Module For Electrical Equipment

Product Description

SF6 is widely used globally as the dielectric medium in high-voltage circuit breakers, electrical switchgear, and other electrical equipment. Additionally, it finds application as a filling material for thermal windows and in magnesium casting. WOBO membrane modules can recover SF6 at or near the intake pressure while simultaneously permeating out unwanted gases. In most applications, WOBO membrane modules can recover over 90% of SF6.

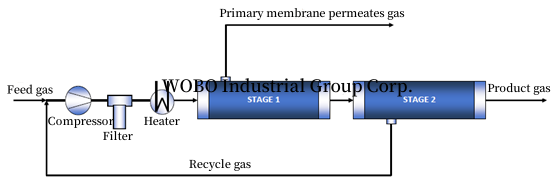

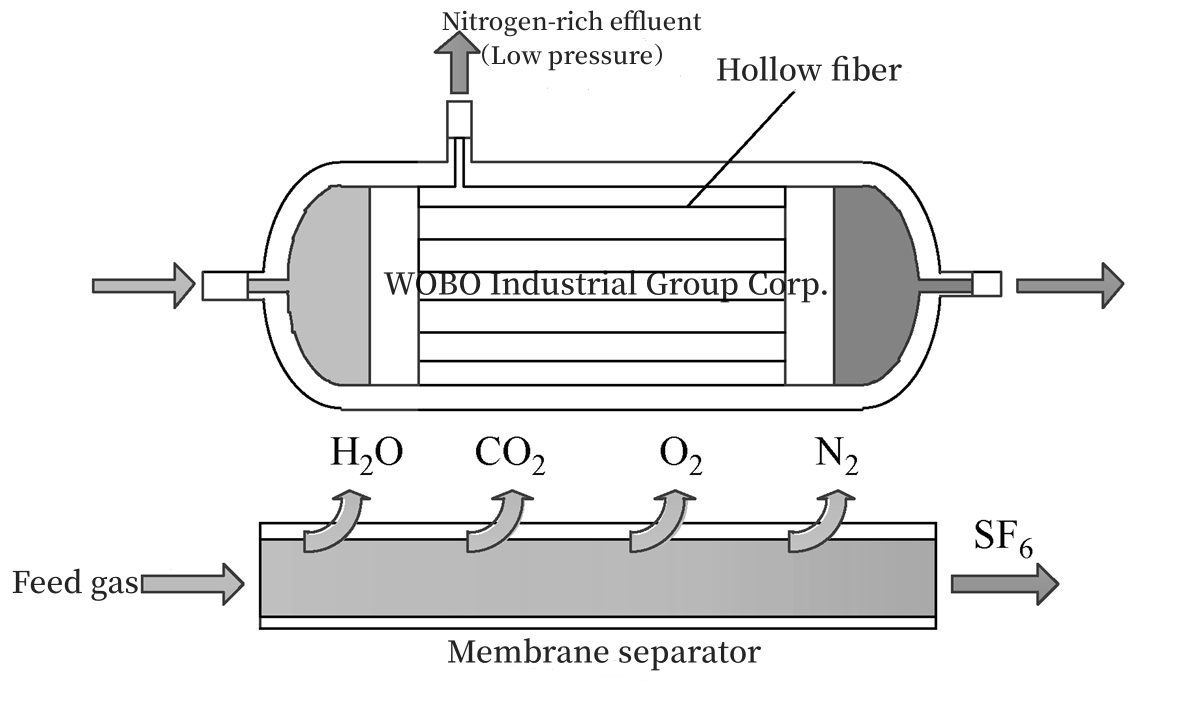

In a standard membrane SF

6

recovery system, the process involves compressing and filtering the raw gas to remove particulate impurities and condensate. Subsequently, the raw gas is heated to the optimal operating temperature before entering the WOBO membrane modules. Within the membrane modules, SF

6

acting as the "slow gas," is retained at the pressure end, while the "fast gases" such as N

2

, O

2

, and H

2

O permeate through the membrane.

Product Performance

Operating temperature up to 80℃

✔

cooling required

✔ Increase water production flux

✔ Increase water production flux

Operating pressure up to 70bar

✔

It can handle viscous liquid

✔ Increase water production flux

✔ Increase water production flux

High recovery rate

✔

Flow range: 1~1500Nm

3

/h

✔

The recovery rate was more than 90%

Detailed Photos

Our Advantages

(1). Experienced:

designed according to user needs

(2). Advanced technology: high recovery rate

(3). Simple solution: no moving parts, little maintenance

(4). No chemical consumption: the system is more environmentally friendly

(2). Advanced technology: high recovery rate

(3). Simple solution: no moving parts, little maintenance

(4). No chemical consumption: the system is more environmentally friendly

Application Fields

(1). Chemical:

Organic solvent nanofiltration (OSN) and end product concentration

(2). Pharmaceutical: Solvent recovery and API concentration

(3). Food & Beverage: Purification and recovery of waste acid lye from cleaning systems

(4). Paint & Coatings: solvent and paint recovery for cleaning water in the production line

(5). Mines & Metals: Acid recovery in wastewater filtration, electrolysis and electrodeposition units

(6). Artificial fibers & Pulp: Recovery of alkali and cellulose from pulp waste

(2). Pharmaceutical: Solvent recovery and API concentration

(3). Food & Beverage: Purification and recovery of waste acid lye from cleaning systems

(4). Paint & Coatings: solvent and paint recovery for cleaning water in the production line

(5). Mines & Metals: Acid recovery in wastewater filtration, electrolysis and electrodeposition units

(6). Artificial fibers & Pulp: Recovery of alkali and cellulose from pulp waste

Project Case

Hot Searches