- Product Details

- {{item.text}}

Quick Details

-

Approval:

-

ISO9001:2008 Certificated

-

Material:

-

Aluminum, Stainless Steel, Iron, Steel,etc

-

Color:

-

Silvery,Black,Gray,etc

-

Surface Treatment:

-

Polishing, Anodized,Painting, etc.

-

Precision:

-

±0.02mm

-

Weight Range:

-

0.5g-15KG

-

OEM or ODM service:

-

Avaliable

-

Application:

-

Medical equipment,Cars,Electric,etc

-

More Material:

-

zinc alloy,aluminium alloy,copper alloy

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WHOLLY

-

Model Number:

-

Wholly 160035

-

Approval:

-

ISO9001:2008 Certificated

-

Material:

-

Aluminum, Stainless Steel, Iron, Steel,etc

-

Color:

-

Silvery,Black,Gray,etc

-

Surface Treatment:

-

Polishing, Anodized,Painting, etc.

-

Precision:

-

±0.02mm

-

Weight Range:

-

0.5g-15KG

-

OEM or ODM service:

-

Avaliable

-

Application:

-

Medical equipment,Cars,Electric,etc

-

More Material:

-

zinc alloy,aluminium alloy,copper alloy

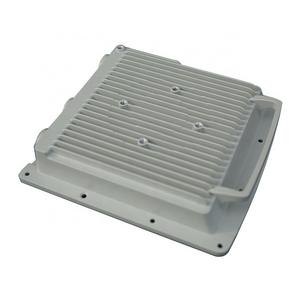

Factory OEM Zinc Die Casting Company,Zamak Injection Die Casting Parts,Zinc Alloy Die Casting Products

Specifications of Factory OEM Zinc Die Casting Company,Zamak Injection Die Casting Parts,Zinc Alloy Die Casting Products

Aluminum die casting parts

Znc die casting parts

Sand casting part

Gravity casting part

CNC parts

Our Advantages:

1. OEM/ODM service,drawings or samples are welcome

2. Customized material or normal materials

3. Strict quality control :ISO9001/2000,Experienced R&D team and skilled worker to track all processes.

4. Small order allowed

5. Competitive price with highest quality,

6. Prompt reply and professional service, timely delivery.

7. Mature market abroad and domestic.

With years' actual experience in work with European and American Companies in engineering, machinery and industry, we are confident to be your supplier of die casting parts.

_______________________________________________________________________________________

___________________________________________________________________________

Equipment of Factory OEM Zinc Die Casting Company,Zamak Injection Die Casting Parts,Zinc Alloy Die Casting Products

——————————————————————————————————————————————————

Testing equipment of Factory OEM Zinc Die Casting Company,Zamak Injection Die Casting Parts,Zinc Alloy Die Casting Products

__________________________________________________________________________________________

Manufacture Capability of Factory OEM Zinc Die Casting Company,Zamak Injection Die Casting Parts,Zinc Alloy Die Casting Products

| Typical | Feasible | |

| Shapes: |

Thin-walled: Complex

Solid: Cylindrical Solid: Cubic Solid: Complex |

Flat

Thin-walled: Cylindrical Thin-walled: Cubic |

| Part Size: | Weight: 0.5g-200KG | |

| Material: |

Metal

Carbon Steel Stainless Steel Aluminum Copper Nickel |

Cast Iron Lead Magnesium Tin Titanium Zinc |

| Surface finish -Ra: | 3.2 - 12.5 μmm | 6.3 - 12.5 μmm |

| Tolerance: | ± 0.1 mm | ± 0.05 mm |

| Max wall thickness: | 1.5 - 20 mm | 0.6 - 127 mm |

| Advantages: |

Can form complex shapes and fine details Many material options High strengh parts Very good surface and accuracy Little need for secondary machining |

|

| Disadvantages: |

Time-consuming process High labor cost High tooling cost Long lead time possible |

|

| Applications: |

Turbine blades, armament parts, pipe fittings, lock parts, hand tools, jewelry |

1. Drawing control

Confidentiality–Be confidential to the customers’drawings.

Check- Technician checks the drawings and confirms dimensions

Confirmation – Confirm the production process & inspection process according to the drawings

2. Mold making control

Inspect the dimensions and material according to drawing.

Send test reports and photos to customers.

3. Raw Casting control

Produce according to the production tracking form

Use advanced inspection equipments to ensure internal quality of the product.

Check the test bar and record relevant information to each bulk.

Send the photos and test data of each step to customers.

4. Machining process control

Produce the samples according to the confirmed casting process.

Train the relevant staff before producing according to the machining and inspection process.

Our inspector will track the quality and time of the products during producing. Any problems on quality and process must be feedback to our customers.

Do the finial inspections to the products and send the relevant data and finished product photos to the customers.

5. Packing and Delivery control

Determine the size & material of the box according to the shape & number of products.

Taking different anti-rust protection to products according the delivery time

Put dimensional reports, chemical & mechanical documents, test bar and photos into the packing box

Send the photos of whole packing process to customers.

We are manufacture which mainly produces pump parts, valve parts, cylinder parts, tractor parts, lathe body, furnace parts and so on. We can also supply you other castings according to your requirements.

We promise to supply you perfect design, professional quality control, competitive prices and excellent after-services

_____________________________________________________________________________

Trade & Market of Factory OEM Zinc Die Casting Company,Zamak Injection Die Casting Parts,Zinc Alloy Die Casting Products

International businessmen

______________________________________________________________________________________

International Certification

__________________________________________________________________________________________

Contact