- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Ruding

-

Model Number:

-

Ball

-

Place of Origin:

-

Anhui, China

-

Tolerance:

-

ABEC-1,ABEC-3,ABEC-5,ABEC-7

-

Material:

-

GCR-15,Chrome steel,Carbon steel

-

Certificate:

-

ISO9001:2015

-

Application:

-

cranes, Excavators, Tower cranes

-

Lubrication:

-

Oil/Grease

-

Rolling elements:

-

Steel ball / Cylinder Roller

-

Mounting hole:

-

Through hole/Tapped hole

Quick Details

-

Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

-

Feature:

-

CROSS ROLLER

-

Seals Type:

-

Rubber Sealed

-

Brand Name:

-

Ruding

-

Model Number:

-

Ball

-

Place of Origin:

-

Anhui, China

-

Tolerance:

-

ABEC-1,ABEC-3,ABEC-5,ABEC-7

-

Material:

-

GCR-15,Chrome steel,Carbon steel

-

Certificate:

-

ISO9001:2015

-

Application:

-

cranes, Excavators, Tower cranes

-

Lubrication:

-

Oil/Grease

-

Rolling elements:

-

Steel ball / Cylinder Roller

-

Mounting hole:

-

Through hole/Tapped hole

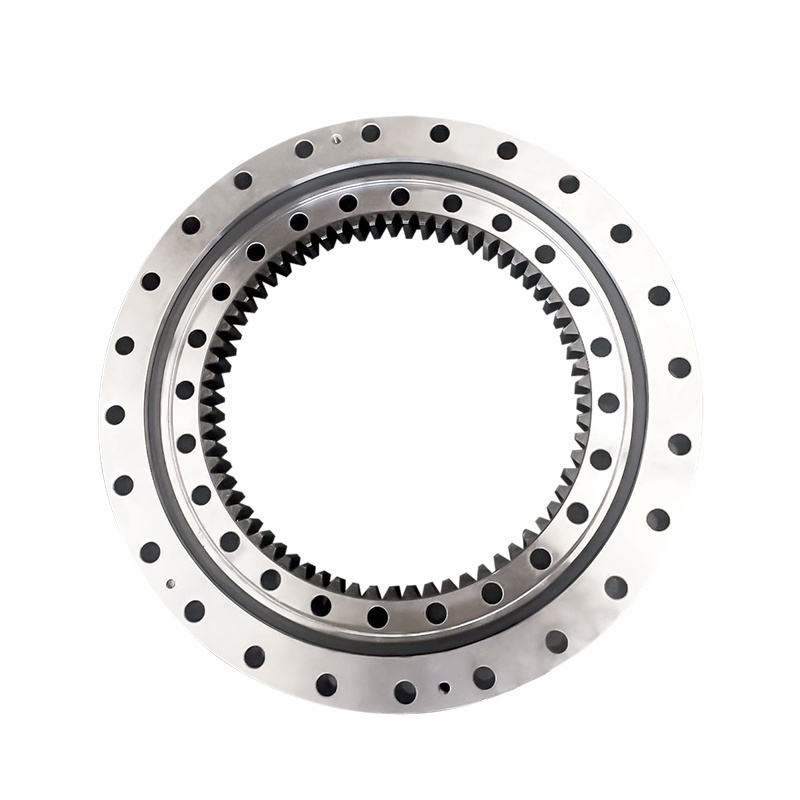

With the tough, heavy-duty conditions of the mining industry, excavators, bucket wheel excavators and stackers / reclaimers are up against a real challenge. Slewing bearing solutions are vital for the performance and reliability of these applications.

Thanks to a high carrying capacity and high resistance to overturning moments, Ruding Steel slewing bearing solutions improve:

* Machinery reliability

* Operator comfort

* Working accuracy

And, as a result, increase the availability and productivity of the excavator.

Ruding Steel slewing bearing solutions are available in different designs to meet the requirements of mini excavators as well as giant shovels. With an Ruding Steel centralized lubrication system, the Ruding Steel slewing bearing solutions become even more efficient.

Specifications:

|

Slewing Turntable Bearing Type

|

Single row four point contact ball slewing bearing

Single row crossed cylindrical roller slewing bearings

Double row crossed cylindrical roller slewing bearings

Double row ball slewing bearings

Double row Roller/ball combination slewing bearing Three-Row Roller Slew Ring Bearing

Wind power bearings

Non-standard customized slewing bearing with inner/ outer gear

|

|

Rollng elements

|

Steel ball / Cylinder Roller

|

|

Bearing Material

|

50Mn/42CrMo/42CrMo4V /Customized

|

|

Cage Material

|

Nylon/ steel /copper

|

|

Structure

|

taper pin, mounting holes, inner ring, grease fitting, load plug, seals, roller, spacer balls or separators

|

|

Outer diameter

|

50-10000mm

|

|

Bore size

|

50-10000mm

|

|

Mounting hole

|

Through hole/Tapped hole

|

|

Raceway hardness

|

55-62HRC

|

|

Inner&outer ring

modulation hardness |

229-269HB/Customized

|

|

Gear type

|

No gear, Internal gear, External gear

|

|

Certificate

|

SGS, ISO9001

|

|

Application area |

Ladle turret, Stacker crane, Bucket wheel machine, Solar heliostat Tracking System, port crane, Cabling machine, tower crane, offshore platform, ferris wheel, Palletizing robot, Rotary metallurgical furnace, can packing machine, Wind blade transporter, shield tunneling machine, tube push bench, excavator

|

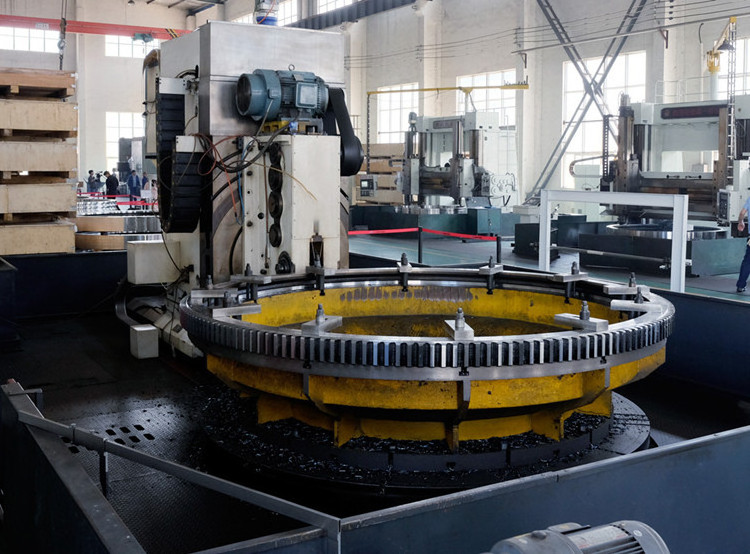

Manufacturing process:

Rraw matrial -- Forging press -- Ring Mill -- Heat Treatment -- Turnning machine -- Final inspection --

Assembly

-- Drilling -- Introduction hardening -- Gear cutting

-- Packing -- Shipping.

1. OEM and customized service.

2. Full machining, primer coating, surface treatment.

3. Complete material testing process.

4. Quality control

Please contact us for more information and quotations.