- Product Details

- {{item.text}}

Quick Details

-

Part name:

-

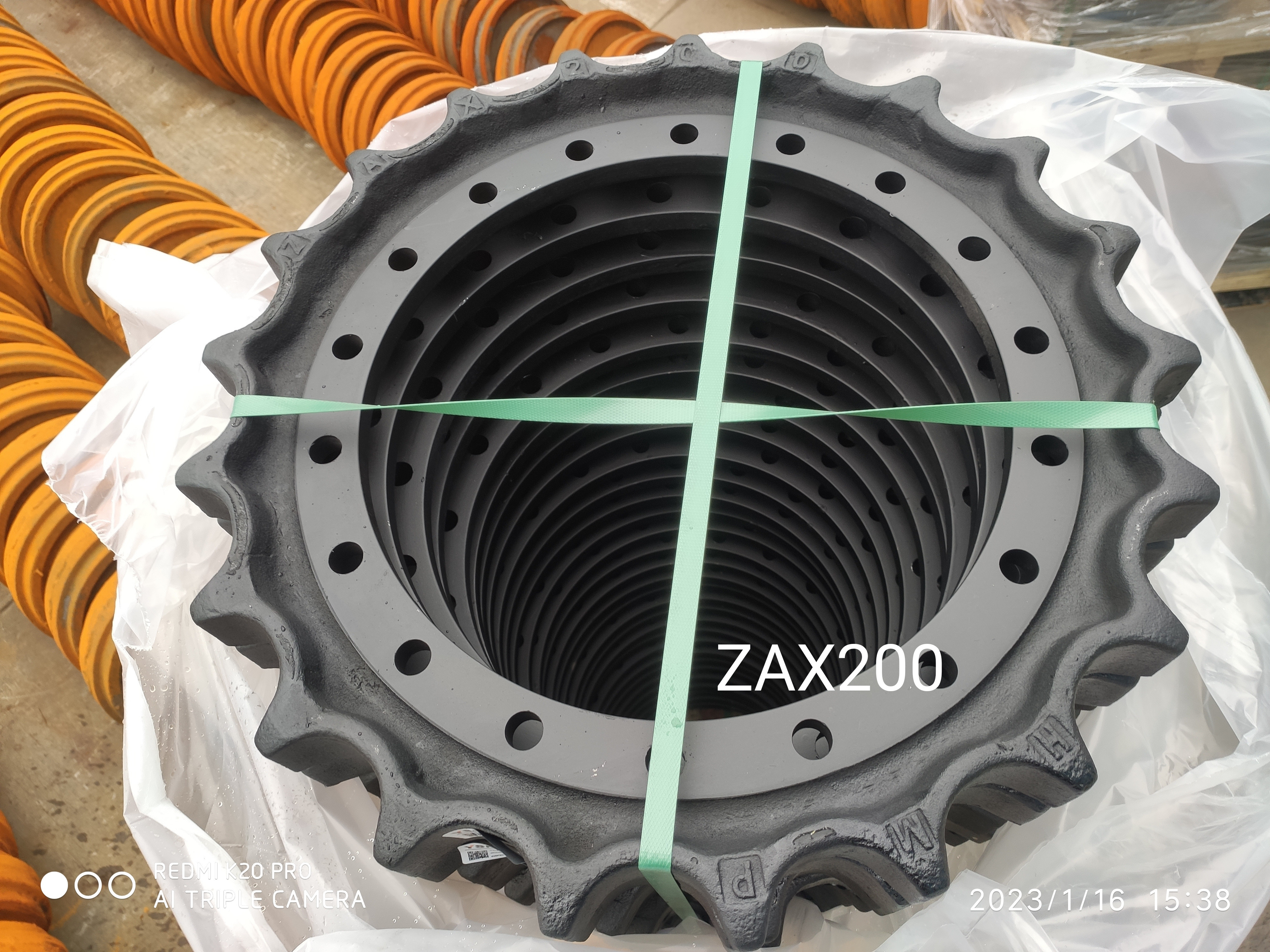

kubota mini excavator sprocket

-

Material:

-

steel alloy

-

Surface hardness:

-

HRC45-55

-

Technique:

-

Forging casting

-

warranty time:

-

2000 working hours

-

Certification:

-

ISO:9001/14001

-

Finish:

-

smooth

-

MOQ:

-

20 pieces

-

Delivery time:

-

within 30days after contract established

-

weight:

-

20kg

Quick Details

-

Marketing Type:

-

kubota mini excavator sprocket

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

YSM

-

Part name:

-

kubota mini excavator sprocket

-

Material:

-

steel alloy

-

Surface hardness:

-

HRC45-55

-

Technique:

-

Forging casting

-

warranty time:

-

2000 working hours

-

Certification:

-

ISO:9001/14001

-

Finish:

-

smooth

-

MOQ:

-

20 pieces

-

Delivery time:

-

within 30days after contract established

-

weight:

-

20kg

Product Description

|

Material

|

steel alloy

|

|

Surface hardness

|

HRC45-55

|

|

Technique

|

Forging casting

|

|

warranty time

|

2000 working hours

|

|

Certification

|

ISO:9001/14001

|

|

Finish

|

smooth

|

|

MOQ

|

1pieces

|

|

Delivery time

|

within 30days after contract established

|

our top-of-the-line Kubota Mini Excavator Sprocket, designed to enhance the efficiency and performance of your mini excavator. Made with the highest quality materials, our sprocket boasts outstanding durability and strength, ensuring long-lasting productivity for your machine.

The Kubota Mini Excavator Sprocket is specifically designed to fit perfectly onto your machine, delivering maximum power to the tracks and facilitating smooth movement on varied terrains. With its precision engineering, our sprocket ensures optimum traction and stability, preventing slippage and enhancing overall performance.

Our Kubota Mini Excavator Sprocket features precise machining and superior heat treatment, which delivers excellent wear resistance and strength. This makes it ideal for tough applications, including construction, mining, and demolition projects that require heavy-duty equipment.

At our company, we prioritize exceptional quality and durability, ensuring that our Kubota Mini Excavator Sprocket exceeds industry standards. Our product is backed by a 12-month warranty, providing you with peace of mind and assurance that you have invested in the best.

In summary, the Kubota Mini Excavator Sprocket is a reliable, sturdy, and efficient accessory that is fundamental to the productivity and performance of your mini excavator. It's the perfect choice for contractors and industrial operators who want to achieve maximum output while minimizing downtime and maintenance costs. Get in touch with our team to place your order or get a quote today!

|

PC50 PC60-3/5/6/7

|

PC65-5

|

PC100-3/5/6

|

PC120-3/5/6

|

PC180

|

|

PC180LC-3/5

|

PC200-1/2/3/5/6/7

|

PC210-6

|

PC220-3/5/7

|

PC240-3/5

|

|

PC300-3/5/6

|

PC350/360

|

PC400-3/5

|

PC400-6

|

PC450

|

|

CAT311/330

|

E120/180/320/322

|

E200B/318B

|

EC210/290

|

EX60-2/3

|

|

EX90/100/120

|

EX100-3/120-3

|

EX100M/100M-5

|

EX130H-5

|

EX200-1/2/3/5

|

|

EX270

|

EX300-1/2/3/5

|

EX300LC-3/5

|

EX330

|

EX400-1/2/3/5

|

|

EX450

|

UH04 UH063/081/083

|

UH045-7

|

UH07-5

|

DH180

|

|

DH200LC

|

DH220-3/5

|

DH280-3

|

DH302

|

HD850/1250/1250-7

|

|

HD400/450/500/700/770/820

|

SK07N2

|

SK60/200/210

|

SK200-3/220-3

|

SK300/320/909

|

|

SH60/65/120/160/200/430

|

LS2800FJ1/2

|

SD7

|

R55/200/220/280/MX292

|

RH6

|

|

MA110

|

MS110-5

|

MS180-3

|

K907-2

|

D20/30/31/155

|

|

D4C/4D

|

|

|

|

|

|

Casting

|

|

|

Forging

|

|

|

D5

|

Segement Group

|

|

D50/D50A

|

Segement Group*9(3T)

|

|

D50/D50A

|

Segement Group*9(3T)

|

|

D6C/6D

|

Segement Group*5(5T)

|

|

D6D/D6C

|

Segement Group*5(5T)

|

|

D60/65

|

Segement Group*9(3T)

|

|

D7G/7E/7F

|

Segement Group*5(5T)

|

|

D7G/7E/7F

|

Segement Group*5(5T)

|

|

D85

|

Segement Group*9(3T*7+2T*2)

|

|

D85

|

Segement Group*0(3T*7+2T*2)

|

|

D85ESS-2

|

Segement Group*9(3T)

|

|

D85ESS-2

|

Segement Group*9(3T)

|

|

T120/140

|

Segement Group

|

|

|

|

|

D60/65

|

Segement Group*9(3T)

|

|

|

|

* For track-type machines ranging from 1 to 300 tons.3, 4, 5 and 6 teeth. More than 80 different segment groups, to match any chain or application.

* YSM segments are through hardened for improved wear resistance. High surface, depth and core hardness means YSM segments provide long wear life, resistant to bending, breakage and maximum hardware retention.The bolt-on design reduces your machine downtime.

* Segments are hot forged for optimum internal grain flow.

Through hardened for high surface hardness (HRC > 50) and tough core (HRC 45)

Specific low alloyed boron steel is used to achieve high rdenability

Precise design and accurate machining of the mounting surfaces ensure best performance

* YSM segments are through hardened for improved wear resistance. High surface, depth and core hardness means YSM segments provide long wear life, resistant to bending, breakage and maximum hardware retention.The bolt-on design reduces your machine downtime.

* Segments are hot forged for optimum internal grain flow.

Through hardened for high surface hardness (HRC > 50) and tough core (HRC 45)

Specific low alloyed boron steel is used to achieve high rdenability

Precise design and accurate machining of the mounting surfaces ensure best performance

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Popular Model

Certifications

Exhibition

Company Profie

Fujian Yongsheng Machinery Parts Co.,Ltd is located in Quanzhou City, Fujian Province, which is one of the most developed regions of China Machinery Manufacturing. The company was established in 2003, after approximately 15 years' effort, and now it is one of the leading construction machinery parts and auto parts manufacturers in CHINA.

In addition, the company strictly implemented ISO9001 Quality Management System and ISO14001 Environmental Management System so as to provide the excellent quality's products for customers, and the products have been widely recognized by our domestic and international consumers. Our products consist of Undercarriage Parts and Ground Engaging Tools for bulldozer and excavator such as Track link, Track roller, Carrier roller, Sprocket, Idler, Track shoe, Cutting edge, End bit, Tooth, Bucket,Track pin, Track bush, Engine parts, Track bolt & nuts, and Auto parts U-bolt, Centre bolt, Wheel bolt and other related parts. A complete sales network has been set up in a lot of countries, such as USA, Canada, UK, Singapore, Russia, Brazil and etc. "Yongsheng Machinery" will be your reliable partner forever。

In addition, the company strictly implemented ISO9001 Quality Management System and ISO14001 Environmental Management System so as to provide the excellent quality's products for customers, and the products have been widely recognized by our domestic and international consumers. Our products consist of Undercarriage Parts and Ground Engaging Tools for bulldozer and excavator such as Track link, Track roller, Carrier roller, Sprocket, Idler, Track shoe, Cutting edge, End bit, Tooth, Bucket,Track pin, Track bush, Engine parts, Track bolt & nuts, and Auto parts U-bolt, Centre bolt, Wheel bolt and other related parts. A complete sales network has been set up in a lot of countries, such as USA, Canada, UK, Singapore, Russia, Brazil and etc. "Yongsheng Machinery" will be your reliable partner forever。

FAQ

Hot Searches