- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1500*3000mm

-

Cutting Thickness:

-

Depending on the materail

-

Control Software:

-

Cypcut/NC studio

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LINTCNC

-

Weight (KG):

-

3000 KG

-

Core Components:

-

Laser source

-

Product name:

-

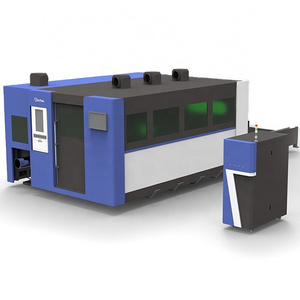

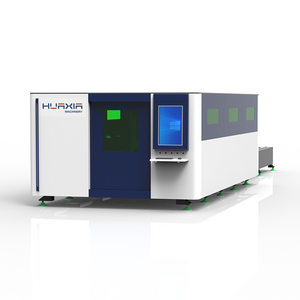

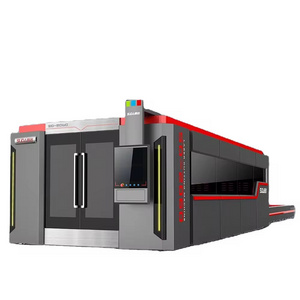

LT-L3015 Fiber laser cutting machine

-

Working area:

-

1500*3000mm working area

-

Laser source:

-

1000/1500/2000/3000W Raycus/ MAX fiber laser source

-

Bed structure:

-

High rigidity welded steel framework

-

Working Table:

-

Blade table

-

Guide rail:

-

Taiwan Hiwin linear square guide rail 25mm

-

Transmission:

-

X,Y with helical gear rack ,Z with TBI ball screw

-

Motor & driver:

-

FUJI servo motor & driver, X,Y axis 750w, Z axis 400w

-

Control system:

-

FSCUT 1000S/2000C control system

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

Depending on the materail

-

Cooling Mode:

-

Air Cooling

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1500*3000mm

-

Cutting Thickness:

-

Depending on the materail

-

Control Software:

-

Cypcut/NC studio

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LINTCNC

-

Weight (KG):

-

3000 KG

-

Core Components:

-

Laser source

-

Product name:

-

LT-L3015 Fiber laser cutting machine

-

Working area:

-

1500*3000mm working area

-

Laser source:

-

1000/1500/2000/3000W Raycus/ MAX fiber laser source

-

Bed structure:

-

High rigidity welded steel framework

-

Working Table:

-

Blade table

-

Guide rail:

-

Taiwan Hiwin linear square guide rail 25mm

-

Transmission:

-

X,Y with helical gear rack ,Z with TBI ball screw

-

Motor & driver:

-

FUJI servo motor & driver, X,Y axis 750w, Z axis 400w

-

Control system:

-

FSCUT 1000S/2000C control system

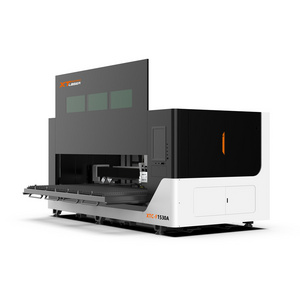

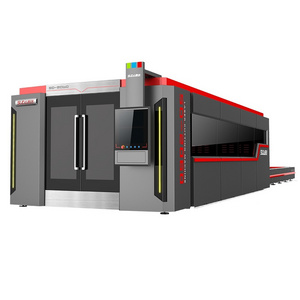

3015 1kw 1.5kw 2kw fiber laser cutting machine full enclosed cover with auto exchange table for sheet metal cutting

Product Description

Main configuration:

Fiber laser cutting machine adopting world famous Germany fiber laser source and USA laser cutting head and dynamic focus system,it can cut and punch different kinds of metal material with high precision and high speed. Since laser is transmitted by fiber ,it is no need to maintenance or adjusts the laser optical path , it greatly reduces the machines fault rate and prolongs the working life. Large format cutting area meets the demands of various kinds of metal processing.

It is widely used for carbon steel, stainless steel, aluminum, copper and other metal materials cutting and forming, with high speed, high precision, high efficiency, cost-effective and energy saving. It is the first choice of the metal processing industry.

Fiber laser cutting machine adopting world famous Germany fiber laser source and USA laser cutting head and dynamic focus system,it can cut and punch different kinds of metal material with high precision and high speed. Since laser is transmitted by fiber ,it is no need to maintenance or adjusts the laser optical path , it greatly reduces the machines fault rate and prolongs the working life. Large format cutting area meets the demands of various kinds of metal processing.

It is widely used for carbon steel, stainless steel, aluminum, copper and other metal materials cutting and forming, with high speed, high precision, high efficiency, cost-effective and energy saving. It is the first choice of the metal processing industry.

1.Excellent beam quality:

Smaller focus diameter , high work efficiency, better processing quality.

2. High cutting speed:

2-3 times faster than YAG and CO2 laser .

3.High Stability:

Adopt superior quality fiber laser, stable performance, key parts can reach

4. High efficiency for photoelectric conversion :

Compared with CO2 laser cutting machine, Fiber laser cutting machine has 3 times photoelectric conversion and with energy saving & friendly environment

Advantages:

1. Low cost:

The whole power consumption is only 20-30% of traditional CO2 laser cutting machine.

2.Low maintenance cost:

It is with Optical fiber line transmission, no need reflector lens, can save a lot of maintenance cost.

3.Easy Operation :

Fiber Line transmission, no adjustment of optical path.

4.Super-flexible optical effect :

small volume, compact structure, easy to flexible manufacturing requirements.

Specification

|

Model

|

LT-L3015 Fiber laser cutting machine

|

|

Effective working area

|

1500*3000mm working area

|

|

Laser source

|

1000/1500/2000/3000W Raycus/ MAX fiber laser source

|

|

Laser cutting head

|

Raytools or WSX laser head

|

|

Bed structure

|

High rigidity welded steel framework

|

|

Working Table

|

Blade table

|

|

Guide rail

|

Taiwan Hiwin linear square guide rail 25mm

|

|

Transmission

|

X,Y with helical gear rack ,Z with TBI ball screw

|

|

Motor & driver

|

FUJI servo motor & driver, X,Y axis 750w, Z axis 400w

|

|

Control system

|

FSCUT 1000S/2000C control system

|

|

Software

|

CypOne laser cutting software with BMC 1603 control card

|

|

Chiller

|

S&A, Dual Temperature Control or Hanli brand chiller

|

|

Reducer

|

Japan imported SHIMPO reducer

|

|

Lubrication system

|

Electric automatic lubrication system

|

|

Pressure valves

|

High-pressure(N2,air):2.5MPa(Shuoda)

Low-pressure(O2):1MPa(SMC)

|

|

Electronic Proportional Valve

|

SMC from Japan

|

|

Electronic Components

|

SCHNERDER, Omron

|

|

Max. idling speed

|

80m/min

|

|

Positioning Accuracy

|

±0.03mm

|

|

Re-Positioning Accuracy

|

±0.02mm

|

|

Instruction format

|

G code *.u00 *.mmg *.plt

|

|

Working voltage

|

AC380V, 3 phase,50-60hz(for more than 1000w)

AC220V, single phase, 50-60hz(for 1000w) |

|

Others

|

Tool box, English Manual, Exhaust fan, cutting nozzle, protection mirrors etc

|

Machine details

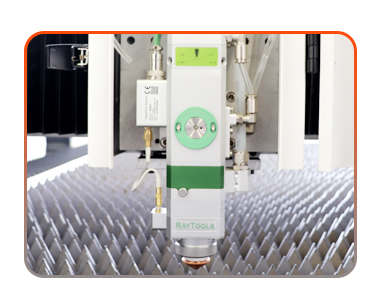

01 RAYTOOLS LASER HEAD

Maunal & Autofocus are both available

Maunal & Autofocus are both available

02 RAYCUS FIBER LASER SORUCE

Which can be 1000w/1500w/2000w/3000w/4000w/

Which can be 1000w/1500w/2000w/3000w/4000w/

6000w/8000w

03 JAPAN SMC ELECTRIC PARTS

Original Japan imported

Original Japan imported

04 HIWIN SQUARE LINEAR GUIDE RAIL

Imported high precision Hiwin square linear guide rail bearings, smooth movement to ensure the machine tools higher accuracy,higher stability, more stable;

Imported high precision Hiwin square linear guide rail bearings, smooth movement to ensure the machine tools higher accuracy,higher stability, more stable;

05 FUJI SERVO MOTOR

Servo motor, 750w for X,Y axis, 400w for Z axis;

Servo motor, 750w for X,Y axis, 400w for Z axis;

06 FUJI SERVO DRIVER

Fuji servo drivers: Built-in micro-subdivision technology and automatic tuning of power-on parameters function; low noise, low vibration, low heat, high torque output features;

Fuji servo drivers: Built-in micro-subdivision technology and automatic tuning of power-on parameters function; low noise, low vibration, low heat, high torque output features;

07 HANLI CHILLER

08 JAPAN REDUCER

Application and sample

This Fiber Laser Cutting machine: Laser Cutting machine is widely used in cutting and shaping for metal plates, pipes (

pipe cutting plus pipe cutting device can be

),

stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass plate,aluminum plate, manganese steel,

all kinds of alloy plates, rare metals etc.

Packing & Delivery

Related video

Hot Searches