- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

3 phase 380v or customized

-

Current:

-

350A

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

custom

-

Use:

-

Welding

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Zhouxiang

-

Weight (KG):

-

1000

-

Voltage:

-

3 phase 380v or customized

-

Current:

-

350A

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

custom

-

Use:

-

Welding

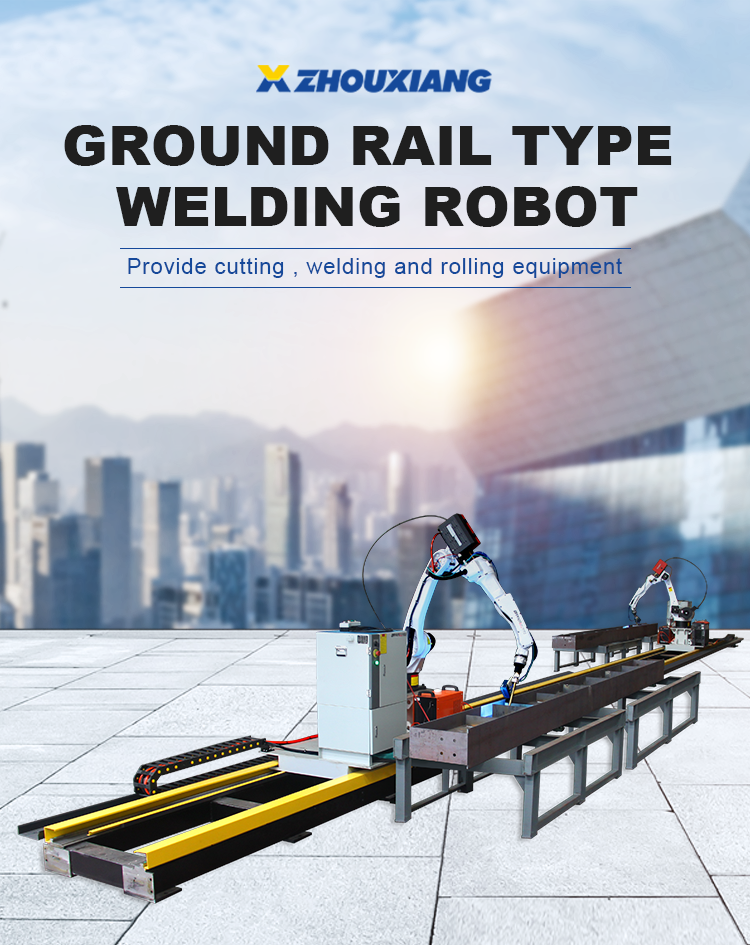

Products Description

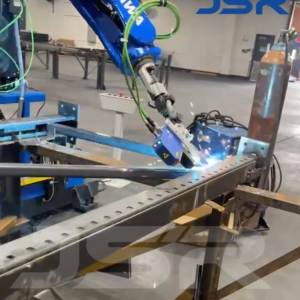

Unique appearance, hollow structure arms and wrists, built-in welding cables, compact structure, can be used for welding operations in narrow spaces, light weight, dust-proof and drip-proof, high safety, equipped with body cover, can be used in various harsh conditions with confidence It has a large environmental working space, fast running speed, and high repeat positioning accuracy. It is suitable for welding applications that have high requirements on weld quality.

Zhouxiang Welding Solution Robotic Durable Visual Seam Tracking Tig Welding Robot Industrial

Parameter

|

Robot

|

1 set of Zhouxiang robot

|

|

Optional welding power source

|

Aotai welding machine and its accessories or Megmeet welding machine and its accessories

|

|

Welding system

|

Zhouxiang teaching-free offline programming welding software, Mingtu line laser tracking

|

|

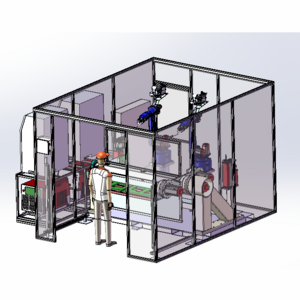

Applicable scenarios

|

Suitable for gusset plates, corbel parts, small structural parts, etc. It can currently be used in H-shaped main beams and

secondary beams of steel structures, small and medium-sized plate units of ship bridges, equipment H-shaped steel columns, equipment platform beams and other structures. |

|

Gun cleaning system

|

SC220A gun cleaning system

|

|

Ground rail length

|

6 meters (optional according to user)

|

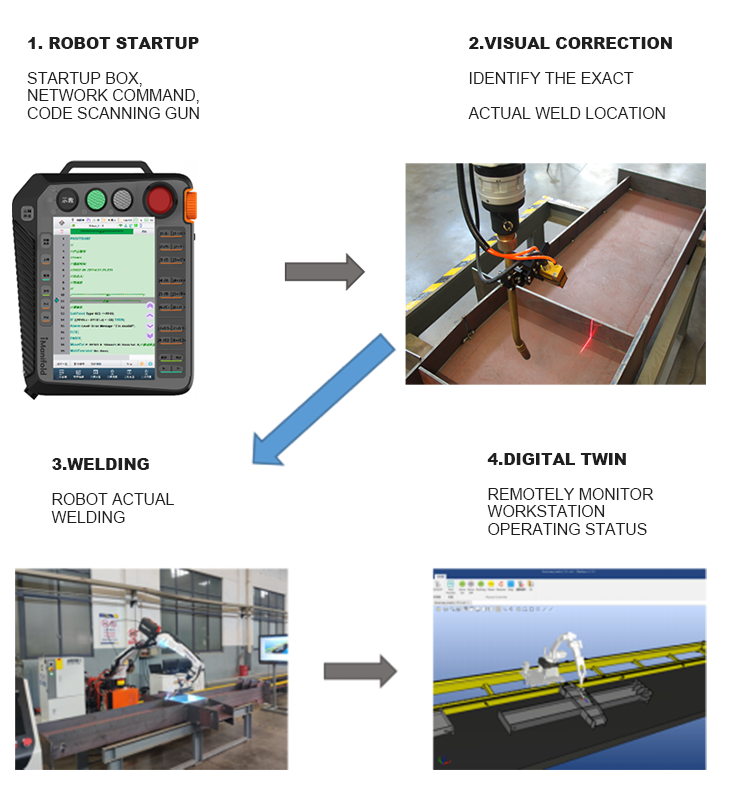

Robot Operation Process

Zhouxiang Welding Solution Robotic Durable Visual Seam Tracking Tig Welding Robot Industrial

Robot Introduction

Zhouxiang Welding Solution Robotic Durable Visual Seam Tracking Tig Welding Robot Industrial

The robot wrist adopts a hollow structure, and the surrounding forearms and five-axis wrists are equipped with built-in wiring channels. The welding gun can rotate 360° without tangling the lines. Compared with the traditional external structure welding gun, the spatial movement range is larger and the operation is more flexible, achieving Optimization of performance and energy efficiency.

Zhouxiang Welding Solution Robotic Durable Visual Seam Tracking Tig Welding Robot Industrial

Application areas: special for welding (gas shielding, argon arc, laser, aluminum, stainless steel, carbon steel)

|

Optional robot models

|

ZXR12-2010

|

ZXR10W-1440-D

|

|

Number of axes

|

6 axes

|

6 axes

|

|

Movement radius

|

2010mm

|

1440mm

|

|

Payload

|

12KG

|

10KG

|

|

Protection level

|

J1, J2 axis IP56 (J3, J4, J5, J6 axis IP67)

|

J1, J2 axis IP56 (J3, J4, J5, J6 axis IP67)

|

|

Installation method

|

floor-standing/bracket type/upside-down type

|

floor-standing/bracket type/upside-down type

|

|

Power capacity

|

4.5KVA

|

4.5KVA

|

|

Input/output signal

|

standard 16 in/16 out 24VDC

|

standard 16 in/16 out 24VDC

|

|

Robot weight

|

313KG

|

210KG

|

|

Repeat positioning accuracy

|

±0.05

|

±0.05

|

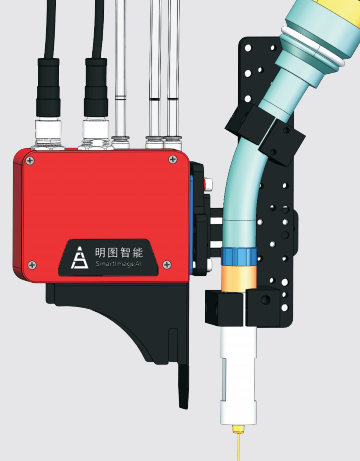

CP350V laser tracker

CP350V is an intelligent line scanning welding seam sensor. It obtains the contour information of the welding seam section through line laser scanning, and guides the robot or welding machine to automatically complete the welding. The image acquisition, processing and welding seam identification functions are completed inside the sensor without the need for an external computer. It has high integration and reduces the overall hardware cost of the system. Resistant to arc light and spatter, intelligently identifies weld seams, and is easy to operate. It has an exquisite structure, compact size, high accessibility, and rich types. It can be selected and used according to the application scenario, and the most suitable parameters can be customized.

Zhouxiang Welding Solution Robotic Durable Visual Seam Tracking Tig Welding Robot Industrial

Gun Clearing System

The SC220A gun cleaning station is a device for cleaning robot welding guns. It is used to automatically clean the welding slag of

the welding gun during robot welding, automatically cut wires, and protect the welding gun nozzle and contact tip, extending the service life of the welding gun and saving money. Reduce consumable costs, maintain good welding quality, and improve welding

efficiency. Simple operation and easy to use.Advantages of gun cleaning stations: 1. The gun clearing time is short and the system

availability is high. 2. Automatically complete the gun cleaning process without manual operation. 3. Prevent quality problems

caused by contamination during welding. 4. Equipped with robot TCP calibration needle.

the welding gun during robot welding, automatically cut wires, and protect the welding gun nozzle and contact tip, extending the service life of the welding gun and saving money. Reduce consumable costs, maintain good welding quality, and improve welding

efficiency. Simple operation and easy to use.Advantages of gun cleaning stations: 1. The gun clearing time is short and the system

availability is high. 2. Automatically complete the gun cleaning process without manual operation. 3. Prevent quality problems

caused by contamination during welding. 4. Equipped with robot TCP calibration needle.

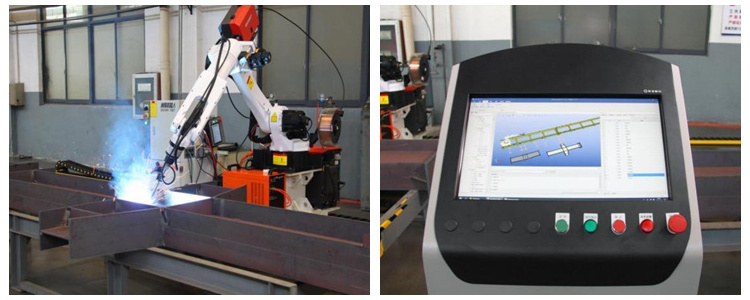

Robot welding software

Zhouxiang Welding Solution Robotic Durable Visual Seam Tracking Tig Welding Robot Industrial

The software can automatically extract welds from drawings without weld marking, reducing the workload of manual participation. With the high-performance 3D engine and robot controller, the automatically created points are simulated and verified to avoid collisions in actual work.

Zhouxiang Welding Solution Robotic Durable Visual Seam Tracking Tig Welding Robot Industrial

Advantage

Zhouxiang Welding Solution Robotic Durable Visual Seam Tracking Tig Welding Robot Industrial

Supports teaching-free for various products such as sandwich panels, truss beams,

bracket

, bridge partitions, and panel stands;

Zhouxiang Welding Solution Robotic Durable Visual Seam Tracking Tig Welding Robot Industrial

There is no need to mark welds at the design stage, and the target weld position can be automatically extracted by importing 3D drawings;

Zhouxiang Welding Solution Robotic Durable Visual Seam Tracking Tig Welding Robot Industrial

No human intervention is required, the robot automatically completes actions such as zero return, transition, position finding, welding, counting, and gun cleaning;

Zhouxiang Welding Solution Robotic Durable Visual Seam Tracking Tig Welding Robot Industrial

No on-site operation is required, the program can be generated at any time and place, and remotely sent to the robot for production according to the specified time;

Zhouxiang Welding Solution Robotic Durable Visual Seam Tracking Tig Welding Robot Industrial

Self-developed offline programming, 1:1 simulation of robot movements, avoids robot interference in advance and avoids collisions;

Zhouxiang Welding Solution Robotic Durable Visual Seam Tracking Tig Welding Robot Industrial

Digital twin technology can display on-site robot trajectory, welding voltage, current, speed and other production information in real time.

Software Operation Process

Main Products

Related Products

Customers of Zhou Xiang

Why Choose Us

Zhouxiang Welding Solution Robotic Durable Visual Seam Tracking Tig Welding Robot Industrial

Wuxi Zhouxiang Complete Set of Welding Equipment Co.,Ltd,founded in 1991,located in Wuxi city, about 100km from Shanghai.We have fixed assets of 150 million yuan,cover an area of 160,000 m2, staff 500 people,including more than 100 engineering and technical personnel.Our company was certified to ISO9001 Quality System Certification firstly in the industry and many products were certified to China Compulsory Certification(CCC).Our products sell well at home and abroad,including Europe,America,Southeast Asia,Middle East and other countries.

Zhouxiang products mainly include cnc cutting machine,H beam production line,box beam production line, welding manipulator, welding rotator, welding positioner, milling machine, shot blasting machine, plate rolling machine, profile bending machine and fiber laser cutting machine etc.We have high sincerity to do business with customers all over the world and establish good friendships.

We actively participate in and hold exhibitions, and reach friendly cooperation with foreign friends. Our cooperation is not only our progress but also the world's progress!

Our Service

FAQ

1.Q: What is the minimum order quantity?

A: 1PCS.

Zhouxiang Welding Solution Robotic Durable Visual Seam Tracking Tig Welding Robot Industrial

2.Q: What are the payment terms?

A: L/C; T/T.

Zhouxiang Welding Solution Robotic Durable Visual Seam Tracking Tig Welding Robot Industrial

3.Q: How long is the delivery time?

A: 30 Days.

Zhouxiang Welding Solution Robotic Durable Visual Seam Tracking Tig Welding Robot Industrial

4.Q:How long is the warranty period?

A: 1 Years.

Hot Searches