Inquiry Us: +8617663732936

- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

600 mm

-

Travel (Y Axis)(mm):

-

600 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Spindle Motor Power(kW):

-

2200W

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WILAND

-

Voltage:

-

AC220V 50/60HZ

-

Dimension(L*W*H):

-

730*810*1450mm

-

Power (kW):

-

2.2

-

Weight (KG):

-

175

-

Product Name:

-

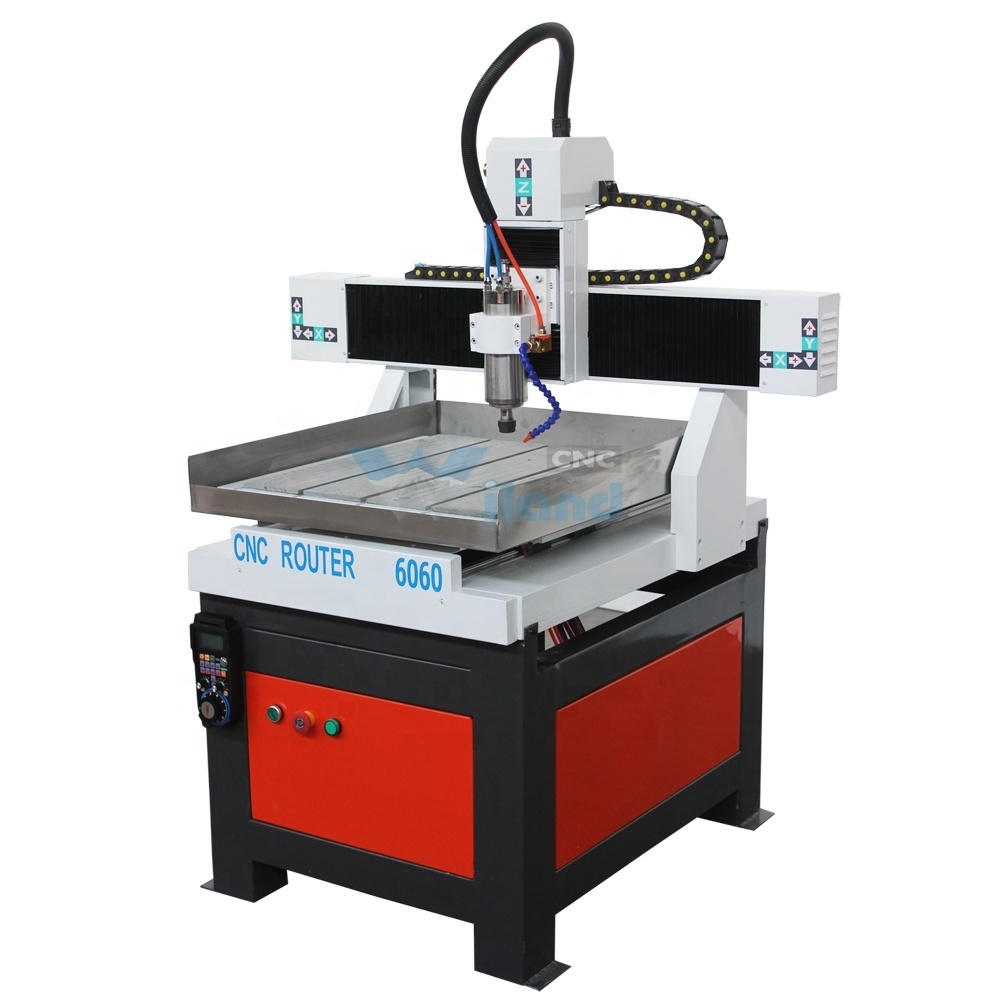

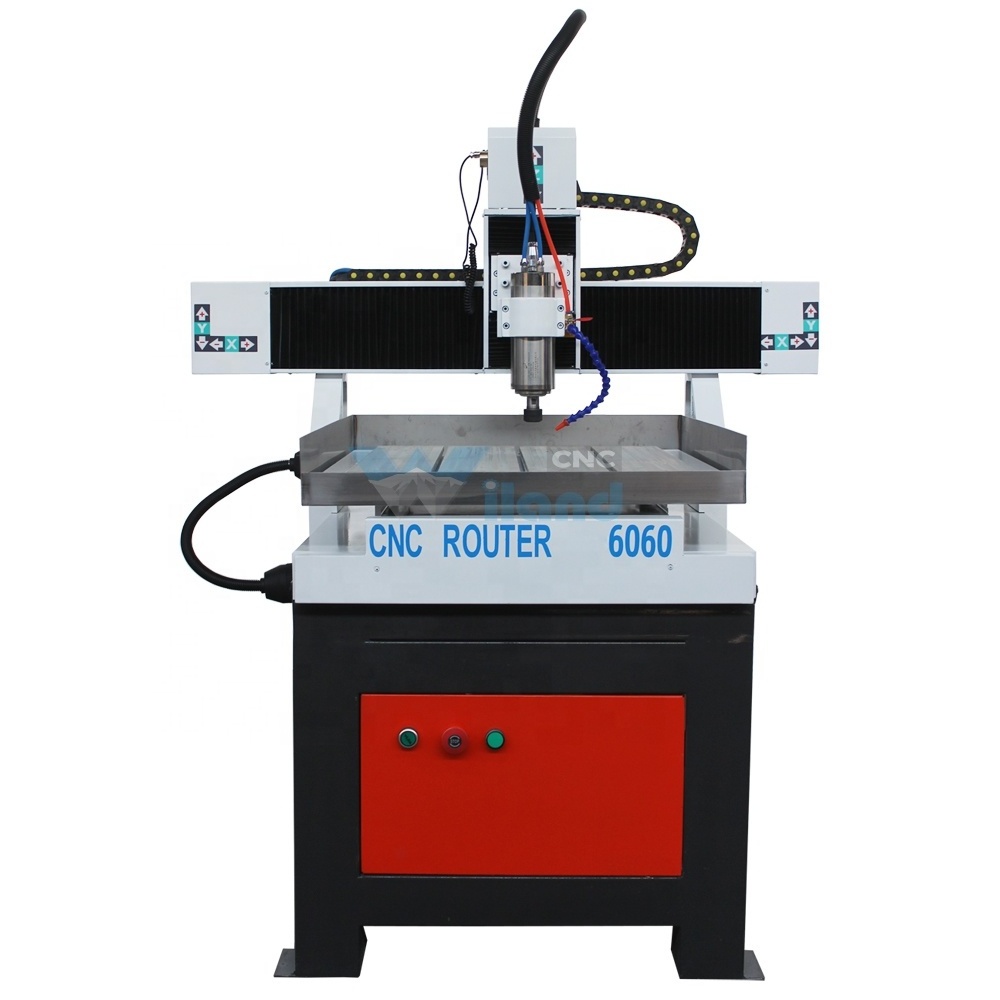

Automatic Metal Engraving CNC Router Machine 6060

-

Spindle:

-

2.2Kw Water Cooling Spindle

-

Spindle Speed:

-

24000Rpm

-

Collet:

-

ER20

-

Control System:

-

Mach3/DSP/NCStudio

-

Guide Rail:

-

Taiwan Hiwin Square Guide Rail

-

Transmission:

-

Ball Screw Transmission

-

Motor:

-

Stepper Motor

-

Driver:

-

Leadshine

-

Working Table:

-

Stainless Steel Water Slot Table

Quick Details

-

Working Table Size(mm):

-

600*600

-

Machine Type:

-

CNC Router

-

Range of Spindle Speed(r.p.m):

-

0 - 24000 rpm

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

600 mm

-

Travel (Y Axis)(mm):

-

600 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Spindle Motor Power(kW):

-

2200W

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WILAND

-

Voltage:

-

AC220V 50/60HZ

-

Dimension(L*W*H):

-

730*810*1450mm

-

Power (kW):

-

2.2

-

Weight (KG):

-

175

-

Product Name:

-

Automatic Metal Engraving CNC Router Machine 6060

-

Spindle:

-

2.2Kw Water Cooling Spindle

-

Spindle Speed:

-

24000Rpm

-

Collet:

-

ER20

-

Control System:

-

Mach3/DSP/NCStudio

-

Guide Rail:

-

Taiwan Hiwin Square Guide Rail

-

Transmission:

-

Ball Screw Transmission

-

Motor:

-

Stepper Motor

-

Driver:

-

Leadshine

-

Working Table:

-

Stainless Steel Water Slot Table

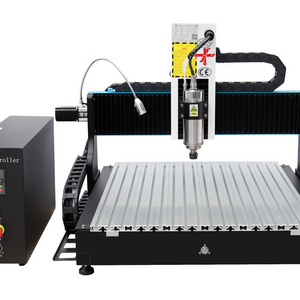

4040 6060 Gemstone Jade Carver Machine Jewelry Metal Engraving Carving Cutting CNC Router Machine For Gem Jewelry

Product Description

Specification

|

Model

|

WLD-4040

|

WLD-6040

|

WLD-6060

|

||

|

Effective Working Area

|

400*400*100mm

|

600*400*100mm

|

600*600*100mm

|

||

|

Materials

|

Whole Cast Aluminum

|

|

|

||

|

Working Table

|

Aircraft aluminum T slot

|

|

|

||

|

Moving Type

|

Table moving

|

|

|

||

|

Guide Rail

|

Hiwin linear square guide rail

|

|

|

||

|

Transmission

|

Ballscrew

|

|

|

||

|

Driving Mode

|

Stepper motor

|

|

|

||

|

Spindle Motor

|

1.5/2.2/3.2KW

|

|

|

||

|

Collet Type

|

ER11/20

|

|

|

||

|

Suitable Tools Diameter

|

3.175mm,4mm,6mm,8mm,10mm,12.7mm

|

|

|

||

|

Voltage

|

AC220V,50/60HZ,Single phase

|

|

|

||

|

Spindle Speed

|

0-24000rpm

|

|

|

||

|

Empty Travelling Speed

|

0-8000mm/min

|

|

|

||

|

Engraving Speed

|

0-6000mm/min

|

|

|

||

|

Machine Accuracy

|

0.05mm

|

|

|

||

|

Resetting Accuracy

|

0.05mm

|

|

|

||

|

Diagonal Error

|

0.5mm

|

|

|

||

|

Control System

|

DSP/Mach3/PCI NCStudio

|

|

|

||

|

Carving Instructions

|

G code * U00*mmg*plt HPGL

|

|

|

||

|

Design Software

|

Ucancam/Artcam/JDPaint/Type3

|

|

|

||

|

Running Environment

|

0-45℃

|

|

|

||

|

Relative Humidity

|

30%-75%

|

|

|

||

|

Optional Items

|

DSP/Mach3/Original NCStudio controlsystem , air cooling spindle ,vacuum table ,dust collector , computer cabinet ,rotary axis ,

wireless handwheel,water cooling system , servo motor , etc |

|

|

||

Machine Information

1.Body small , tight , machine body and gantry whole cast iron or aluminum , stable , no deformation ,little shock , moving stability .

2.Imported high quality ball screw , precision segmentation , to achieve the high precision engraving .

3.Low noise 1.5kw water cooling spindle , high rotated speed (24000rpm) , can realize only diameter 0.1mm tools engraving on the hardness materials .

4.Auto tool calibration help you to set the tools , not break the tool nose , ensuring the workpiece high precision processing .

5.Water cooling system for the metal materials , cooling the tools , avoiding the high temperature breaking tools .

6.High precision gear transmission rotary axis solves the problem for the cylinder processing .

7.Optional control system , NCStudio/DSP/Mach3 , high stability , high efficiency , easy to learn .

8.Continuing working after the break point/power failure , lower the rejection rate .

9.Good software compatibility ,can compatible with the Artcam/Type3/Ucancam/JDPaint such CAD/CAM software , 2D/3D processing , more convenient to using .

Main Parts

Samples

Application

Good at in processing all kinds of small workpiece , widely used in advertising signs , badges , logo , mould construction equipment , mould products , industrial mold , etc .

Applicable materials

Suitable for all kinds of metal , such as copper , aluminum , iron , steel , stainless , alloy , also the acrylic , wood ,MDF , double color board , stone , jade .

Packing & Delivery

Packing Details

1.For the outside, we adopt plywood case.

2.In the middle, the machine is covered by foam, to protect the machine from shaking.

3.For the inside layer, the machine is covered by the waterproof plastic bag.

3.For the inside layer, the machine is covered by the waterproof plastic bag.

Delivery Time

We provide shipping methods such as sea, air, and express.

1. The delivery lead time would be 7-10 working days after recieving the payment.

2. The customer can choose the shipping by sea, by air and even by international express such as FedEx, DHL, TNT, etc. We will

send the cargo by reliable forwarder

We provide shipping methods such as sea, air, and express.

1. The delivery lead time would be 7-10 working days after recieving the payment.

2. The customer can choose the shipping by sea, by air and even by international express such as FedEx, DHL, TNT, etc. We will

send the cargo by reliable forwarder

Hot Searches