- Product Details

- {{item.text}}

Quick Details

-

Application:

-

All construction

-

Design Style:

-

N/A

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YUHONG

-

Model Number:

-

SPU-301

-

Type:

-

waterproof coating, Other Waterproofing Materials

-

Shape:

-

liquid

-

Core Material:

-

N/A

-

Format:

-

N/A

-

Color:

-

BLACK

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Training

-

Project Solution Capability:

-

graphic design, total solution for projects

-

Application:

-

All construction

-

Design Style:

-

N/A

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YUHONG

-

Model Number:

-

SPU-301

-

Type:

-

waterproof coating, Other Waterproofing Materials

-

Shape:

-

liquid

-

Core Material:

-

N/A

-

Format:

-

N/A

-

Color:

-

BLACK

SPU-301

SPU-301

One Component Polyurethane Waterproof Coating

SPU-301 is a one component moisture-curing polyurethane waterproof coating

especially used for horizontal plane. When this coating is applied on surface substrate,

it has chemical reaction with the moisture in the air, and then it will form a seamless

elastomeric rubber waterproof membrane.

- Undergrounds;

- Parking garages;

- Subways in open cut method;

- Channels;

- Kitchen or bathroom;

- Floors, balcony and unexposed roofs;

- Swimming pools, man-made fountain and other pools;

- Top plate at plazas.

- Good tensile strength and elongation;

- Both high and low temperature resistance;

- Strong adhesive;

- Seamless, no pinholes and bubbles;

- Resistance to long-term water erosion;

- Corrosion-resisting and mould-resisting;

- Convenient to apply.

ASTM C 836

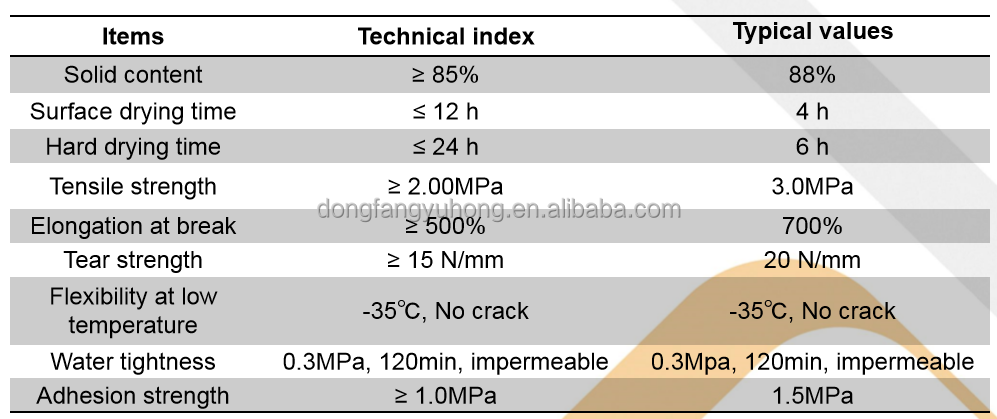

Typical properties

|

Item |

Requirement |

Test Method |

|

Hardness |

≥50 |

ASTM D 2240 |

|

Weight Loss |

≤20% |

ASTM C 1250 |

|

Low temperature crack bridging |

No cracking |

ASTM C 1305 |

|

Film thickness(vertical surface) |

1.5mm ±0.1mm |

ASTM C 836 |

|

Adhesion-in-peel after water immersion |

175N/m |

ASTM C 794 |

|

Optional test after adhesion in peel |

No separation at surface |

ASTM C 836 |

|

Extensibility after hear aging |

6.4mm (note 1) no cracking |

ASTM C 1522 |

|

Stability |

≥6 months |

ASTM C 836 |

SP U-301 is sealed in 20kg pails and transported in wooden cases. Each wooden case can be contained 36 pails of SPU-301.

SPU-301 m aterial s h ould b e s tored by sealed pails at dry and well-ventilated places and protected from sun or rain. The temperature in stored places can not be higher than 40° C. It can not be closed to fire sources. The normal shelf life is 6 months.

SPU-301 is needed to be avoided sunshine and rain . Fire sources are forbidden during transportation.

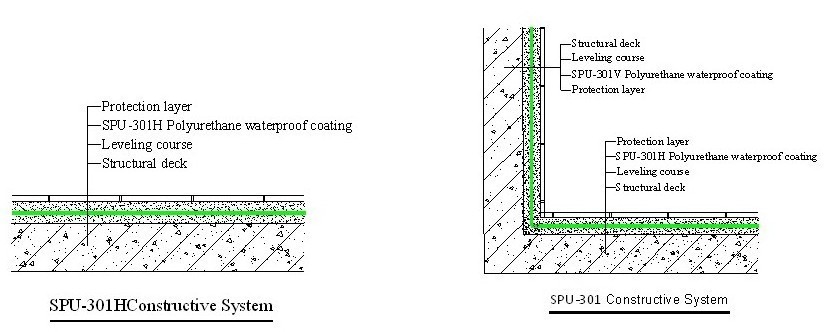

Application System

l Constructive System

The system is basically consisted of substrate, additional layer, waterproof coated membrane and protection layer.

l Coverage

1.7kg per m 2 gives dft 1mm minimum. Coverage may vary with the substrate condition during application.

l Application Method

Surface preparation

Surfaces should be dry, stable, clean, smooth, without pockmarks or honeycombs and free from any dusts, oil or loose particles. Cracks and surface irregularities need to be filled by sealants and do additional waterproofing. For smooth and stable surfaces, this step can be skipped.

Additional layer

Paint SPU-301 as additional layer to enhance at internal and external corners, drain pipes, floor drains or embedded parts.

Application of waterproof coated membrane

It can use rubber scrapers or spray equipments to paint 2 or 3 times. After fully dry, it can be painted again. The normal time between each painting is 24 hour. The direction of second time painting needs to be perpendicular to the first time painting.

Application of protection layer

After waterproof coated membrane is fully dry and meets quality requirements, it can begin application of protection layer.

Notice

l The temperature for application of SPU-301 should be above 5℃.

l SPU-301 needs to be consumed instantly and can not be diluted with solvent.

l The storage and application places should be well-ventilated and no fire.