- Product Details

- {{item.text}}

Quick Details

-

Power:

-

36kw

-

Weight:

-

300 KG

-

Dimension(L*W*H):

-

2500*1400*1500mm

-

Capacity:

-

customized

-

Marketing Type:

-

Hot Product 2023

-

Name:

-

Multi fryer machine

-

Feature 1:

-

Automatic discharge and Automatic mixing

-

Feature 2:

-

Automatic temperature control

-

Material:

-

304ss

-

Oil tank:

-

300-650L

-

Application:

-

Fry Snacks/meats/foods/vegetables/pasta/aquatic

-

Size:

-

1400*800*400mm

-

Heating method:

-

coal, electric, gas

-

Automatic filter system:

-

Oil-water mixture, Pure oil filter

-

Range of Temperature:

-

0-300℃

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fusion

-

Voltage:

-

380v/customized

-

Power:

-

36kw

-

Weight:

-

300 KG

-

Dimension(L*W*H):

-

2500*1400*1500mm

-

Capacity:

-

customized

-

Marketing Type:

-

Hot Product 2023

-

Name:

-

Multi fryer machine

-

Feature 1:

-

Automatic discharge and Automatic mixing

-

Feature 2:

-

Automatic temperature control

-

Material:

-

304ss

-

Oil tank:

-

300-650L

-

Application:

-

Fry Snacks/meats/foods/vegetables/pasta/aquatic

-

Size:

-

1400*800*400mm

-

Heating method:

-

coal, electric, gas

-

Automatic filter system:

-

Oil-water mixture, Pure oil filter

-

Range of Temperature:

-

0-300℃

Fast food chicken deep fryer/ Industrial Electric Gas Potato Chips Frying Automatic Churro Frying Machine And Fryer / Chicken Frying Machine Pressure Fryer Broast Machine Commercial Used Stainless Steel 304 Small Scale Frozen French Fries Making Machine Potato Chips Production Line Commercial Used Stainless Steel 304 Small Scale Frozen French Fries Making Machine Potato Chips Production Line

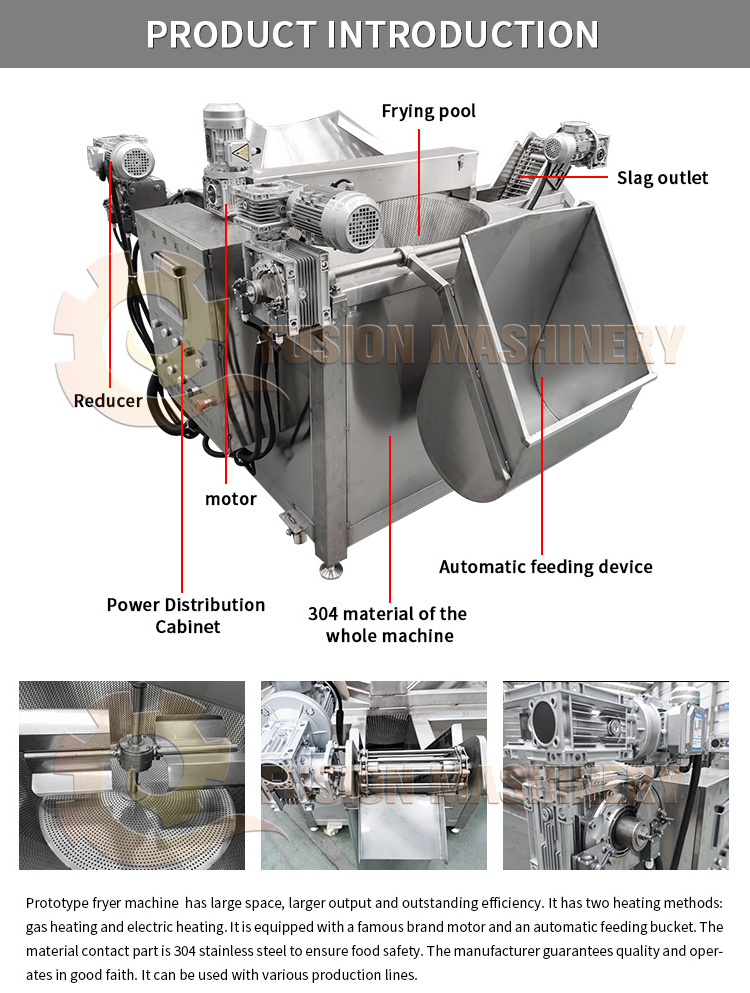

Fusion Automatic Mixing Round Fryer Machine 's Features:

1. Gas or electricity or electromagnetic as heating source.

2. Oil-water separation filting system or pure oil filting system.

3. Automatic mixing, ensure products being uniformly fried and prevent them from compression and adhesion.

4.Automatic discharging and optional automatic feedingthrough motor-driven manner to reduce labor intensity.

5. Automatic temperature control: 0-300°C to be set at your will.

Advantages of this

Automatic Mixing Round Fryer

Machine

:

1. The main heating types for choose: electric heating, coal heating, natural gas heating, LPG heating.

2. Automatic discharge, adopt oil-water mixture new technology, automatic filtering slag, greatly extend the life cycle of frying oil, can be repeatedly used for a long time without replace the oil.

3. Oil and water automatic temperature control respectively, double layers insulation design, frying temperature from 0~260°C adjustable.

4. No oil-smoke, no smell pollution, time saving and environmental protection, compared to the ordinary frying machine, oil saves 50%, electricity or coal saves 40%.

We are professional direct manufacturer for potato chips or french fries making machines in China.

We have different solutions for different demands:

Optional Configurations:

According to different products and demands, this small scale batch fryer machine has following optional configurations:

Frying machine is used for making various fried food, including nut fruits, puffed food, flour product, meat products, seafood, bean products, and so on .

Food frying machine has 2 heating methods: heated by electric and gas.

Brief Introduction of

A

utomatic

M

ixing

R

ound

F

ryer

Machine

:

This semi automatic frying machine adopt oil-water mixture new technology, automatic filtering slag, greatly extend the life cycle of frying oil, can be repeatedly used for a long time without replace the oil, can be used in fried dried fruit nuts, puffed food, meat product,etc, such as potato chips, rice crisp, sweet sticky rice strips, peanut, beans, and fried cake with sugar, squid, fried chicken, etc. The main heating types for choose: electric heating, coal heating, natural gas heating, LPG heating.

Details of Automatic Mixing Round Fryer

Machine

:

01. The network belt transmission adopts frequency conversion stepless speed regulation. The frying time is controllable.

02. The equipment is equipped with an automatic lifting system, the upper hood body and mesh belt can be lifted and lowered, which is easy to clean.

03. The bottom is equipped with a slag discharge system, and the generated residue can be discharged at any time.

04. The use of high-efficiency heat conductivity device, high energy utilization rate, conducive to reducing enterprise costs.

05. With electricity, coal or natural gas as heating energy, the whole machine is made of food-grade 304 stainless steel.

06. The upper and lower double-layer mesh belt is adopted, and the product is sandwiched between the double-layer mesh belt to avoid the product floating.

07. The equipment is equipped with an oil circulation filtration system, which continuously filters oil residue during the production process, reduces the acid price of oil, reduces the color of oil, and prolongs the service life of edible oil by more than 10 times.

1. optional automatic feeding device to reduce labor intensity

2. optional slag scrapping device if the fried products produce much slag and residue

3. optional timer and alarm to remind you when the frying is finished

Main Equipment of Small Scale French Fries Production Line

The frying machine is made of all SUS304 stainless steel, which is beautiful and sanitary; the residue produced in the process of food frying will not be carbonized and blackened due to the function of oil-water separation, and the fried food taste is more fragrant, safer and sanitary, at the same time, the oil consumption is saved; the residue can be effectively discharged by simply draining water. Fry the product with temperature control to make the food more attractive.

| Model | Diameter(mm) | Weight(kg) | Power(kw) | Oil tank |

| FX-1000 | 1000 | 800 | 36 | 400L |

| FX-1200 | 1200 | 1100 | 48 | 600L |

| FX-1500 | 1500 | 1500 | 60 | 1000L |

1. Packing: PP film wrapped around the machine and carefully packed in wooden case to focus on protecting damageable parts.

2. Shipping: From port of Shenzhen, Shanghai, Qingdao, Guangzhou, etc. We also accept land, air, sea transport and

internationalmultimodal transport.

3. Clearance: Our long history makes us the one of the first and most knowledgeable providers of the equipment, our main customers hail from; Canada, the United States, Brazil, Argentina, Japan, Philippines, Australia, Russia, Thailand, the UAE, Poland, Spain, Germany, India, etc.

1. We always welcome customers to visit our manufacturing factory and get to know more about us.

2. Customers can see all the manufacturing workflows when they visit our factory. You can contact with online besides offline:

Tel/ WeChat/ WhatsAPP/ iMessages: +86 155 0374 7612

3. We also send engineers to the customer's place to help with the installation!

Q1: Are you a trading company or a manufactory?

A2: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: The delivet time is based on the exact machine you confirmed.

Q4: How do you offer technical support?

A4:

1. Technical support by phone, email, WhatsApp, Wechat or iMessages around the clock

2. Friendly English version manual

3. Engineer available to service machinery overseas

A5: Normal machine is properly adjusted before dispatch. You will be able to use the mchines immediately. And You will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/ fax/ tel and lifetime technical support.

Q6: How about the spare parts?

A6: After we deal down all the things, we will offer you a spare parts list for your reference.