- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TFZD

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Customize

-

Weight:

-

200 KG

-

Color:

-

Customize

-

Material:

-

Customize

-

Layer(s):

-

Customize

-

Feature:

-

High Screening Efficiency

-

Screen Mesh:

-

Customize

-

Capacity:

-

Large

-

Noise:

-

Low

-

Power:

-

Electricity

-

Machine type:

-

Automatic

-

Product Name:

-

Oil Shale Shaker Sifter Screen Linear Vibrating Sieve Machinery

Quick Details

-

Type:

-

Circular

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TFZD

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Customize

-

Weight:

-

200 KG

-

Color:

-

Customize

-

Material:

-

Customize

-

Layer(s):

-

Customize

-

Feature:

-

High Screening Efficiency

-

Screen Mesh:

-

Customize

-

Capacity:

-

Large

-

Noise:

-

Low

-

Power:

-

Electricity

-

Machine type:

-

Automatic

-

Product Name:

-

Oil Shale Shaker Sifter Screen Linear Vibrating Sieve Machinery

Product Description

Oil Shale Shaker Sifter Screen Linear Vibrating Sieve Machinery

Product Introduction

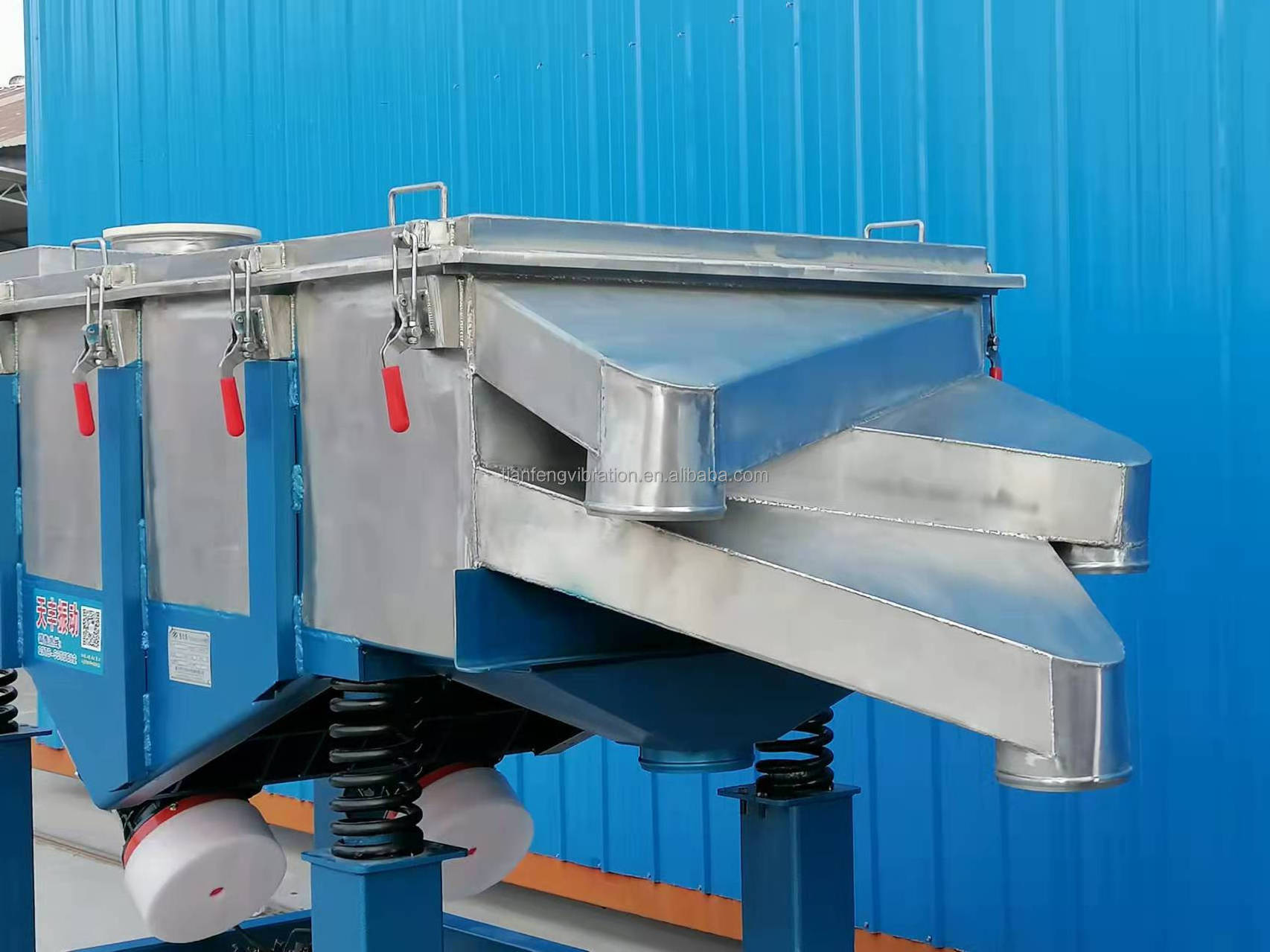

Tianfeng TLZS series linear vibrating screen is composed of vibrating motor, screen box, screen net, vibrating transfer device and vibrating damping device. Tianfeng TLZS series linear vibrating screen can be used for screening powder, particles and other dry materials. At the same time, the equipment can be used for filtering liquid and mucus. The machine can screen raw material to 325 mesh. The machine adopts adjusted excitation power. According to the screening requirement and the filtering requirement of the customers, the linear vibrating screen produced by Tianfeng can be used with single layer and multi-layer, and the screen layer can be designed into 5 layers. Generally speaking, the screen frame of the linear vibrating screen is wooden structure. About the raw material of the contact part, you can choose stainless steel if you need to screen corrosive material. The application industry of the machine is very extensive such as plastic processing, abrasive processing, chemical industry, medicine processing, building material, grain processing, carbon processing, fertilizer processing and other industries.

Technical Characteristics

1. low noise, low consumption, high efficiency, low cost.

2. high screening precision, no dust spillage and pollution, more friendly for environment

3. The linear vibrating machine can be equipped various screen net, and the screen net can be changed easily and conveniently. The service life of machine is very long.

2. high screening precision, no dust spillage and pollution, more friendly for environment

3. The linear vibrating machine can be equipped various screen net, and the screen net can be changed easily and conveniently. The service life of machine is very long.

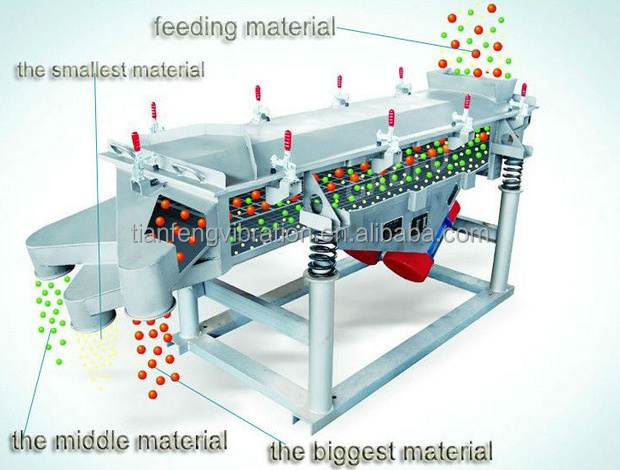

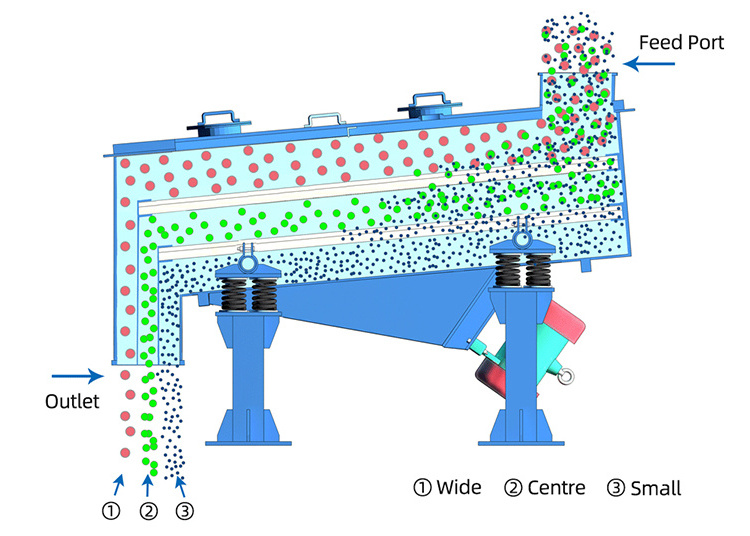

Working Principle

When the eccentric blocks installed the both ends of two sets vibrating motors which are installed on the screen body with

longitudinal producing rated exciting force, the transverse exciting force will be offset with each other, and the longitude

exciting force will be conveyed to the whole screen surface by vibration transfer body. Then, the material will make jump forward motion toward to discharge port. The material which smaller than the screen hole will pass the screen hole and enter into next layer, and the material bigger than screen hole will stay on the screen net and make jump motion continuously. After jumping continuously, the material staying on the screen net will be discharged from discharge port. Because the screening process is reasonable, the machine can screen material by vibration, and you can get the materials with different particles and finish the classification of raw materials.

longitudinal producing rated exciting force, the transverse exciting force will be offset with each other, and the longitude

exciting force will be conveyed to the whole screen surface by vibration transfer body. Then, the material will make jump forward motion toward to discharge port. The material which smaller than the screen hole will pass the screen hole and enter into next layer, and the material bigger than screen hole will stay on the screen net and make jump motion continuously. After jumping continuously, the material staying on the screen net will be discharged from discharge port. Because the screening process is reasonable, the machine can screen material by vibration, and you can get the materials with different particles and finish the classification of raw materials.

Main Function

1. Screening and grading

2. Removing impurities

3. Separating between solid materials and liquid materials

Main Materials

1. Carbon Steel

2.

Semi- Stainless Steel

3. Stainless Steel

Applicable Industries

Tianfeng TLZS series linear vibrating screen can be divided into two kinds: linear vibrating screen for screening dry material and linear vibrating screen for screening liquid material.

Chemical Industry: resin, medicine, cosmestic, plastics, rubber, ceramic, refractory

Ceramic Industry: grinding material, abrasive, glass, aluminium, porcelain mud, clay mud, refractory, quartz sand, titanium

powder, powder and etc.

Food Industry: sugar, monosodium glutamate, salt, juice, starch, milk powder, grain processing, soybean milk, egg powder, protein powder and etc.

metallurgical Industry: ore, titanium oxide, zinc oxide, casting sand, metallurgical powder, super-hard alloy, electromagnetic

material, aluminium powder, metal powder, metal particles and etc.

Liquid Industry: oil paint, paint, and other liquid with viscosity

Other Industry: carbon black, carbon, addictive , activated carbon and etc.

Ceramic Industry: grinding material, abrasive, glass, aluminium, porcelain mud, clay mud, refractory, quartz sand, titanium

powder, powder and etc.

Food Industry: sugar, monosodium glutamate, salt, juice, starch, milk powder, grain processing, soybean milk, egg powder, protein powder and etc.

metallurgical Industry: ore, titanium oxide, zinc oxide, casting sand, metallurgical powder, super-hard alloy, electromagnetic

material, aluminium powder, metal powder, metal particles and etc.

Liquid Industry: oil paint, paint, and other liquid with viscosity

Other Industry: carbon black, carbon, addictive , activated carbon and etc.

Processing Procedure

|

Technical Parameters

|

|

|

|

|

|

|

|

|

||||||||

|

Model

|

Screen Surface Square (m2)

|

Screen Surface Angle (o)

|

Screen Hole

Size (mm)

|

Capacity (t/h)

|

Vibration Frequency

|

Double Amplitude (mm)

|

Power (kw)

|

Weight (kg)

|

||||||||

|

TLZS924

|

2.16

|

0-10

|

~50

|

~130

|

960

|

~7

|

2x0.75

|

1500

|

||||||||

|

2TLZS924

|

2.16

|

0-10

|

~50

~60

|

~100

|

960

|

~8

|

2x1.5

|

1700

|

||||||||

|

TLZS1230

|

3.6

|

0-10

|

~50

|

~180

|

960

|

~8

|

2x2.2

|

2300

|

||||||||

|

2TLZS1230

|

3.6

|

0-10

|

~50

~30

|

~150

|

960

|

~7

|

2x2.2

|

2650

|

||||||||

|

TLZS1536

|

5.4

|

0-10

|

~80

|

~380

|

960

|

~8

|

2x3.0

|

3400

|

||||||||

|

2TLZS1536

|

5.4

|

0-10

|

~80

~50

|

~300

|

960

|

~8

|

2x3.0

|

4000

|

||||||||

|

TLZS1540

|

6.0

|

0-10

|

~120

|

~400

|

960

|

~9

|

2x3.7

|

4200

|

||||||||

|

2TLZS1540

|

6.0

|

0-10

|

~120

~80

|

~350

|

960

|

~9

|

2x3.7

|

5100

|

||||||||

|

2TLZS1860

|

10.8

|

0-10

|

~120

|

~600

|

960

|

~9

|

2x5.5

|

5210

|

||||||||

Packaging&Shipping

After you place the order and pay the deposit in our company, we will start to arrange the production and contact the ocean freight transportation agency to reserve the position. Two days before the end of production, you need to complete the final payment. Then, we will inform the ocean cargo transportation agent company that it is ready to come to the factory to pull the goods to the port. On the day of delivery, we will send you the factory video and pictures, and mark the corresponding English name of each product and product parts with a marker to prevent you from not knowing what each part is after receiving the goods. At the same time, we will put the English version of the product instructions in the cargo box. We generally select freight forwarders with preferential prices for customers to deliver goods for you. The shipping method can be FOB or CIF. You can also choose EXW, and then contact the goods agent company yourself. About the packaging method and the shipping method, if you have any different idea, welcome to contact us.

Company Profile

Hot Searches