- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

500

-

Name:

-

wood sawdust charcoal carbonization furnace

-

Raw material:

-

coconut shell, bamboo, wood logs, branches, wood waste, etc

-

Keywords:

-

charcoal maker

-

Capacity:

-

100-3000kg/24h

-

Application:

-

Charcoal Bio Char Production Plant

-

Usage:

-

Carbonize biomass material into charcoal

-

Advantage:

-

High efficiency, energy saving, low cost

-

Carbonization time:

-

6-8 Hours/batch

-

Fuel:

-

Firewood, electricity, natural gas, LPG, coal

-

Steel:

-

Vessel steel

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

wood carbonization stove

-

Dimension(L*W*H):

-

2.1m*1.3m*1.7m

-

Weight (KG):

-

500

-

Name:

-

wood sawdust charcoal carbonization furnace

-

Raw material:

-

coconut shell, bamboo, wood logs, branches, wood waste, etc

-

Keywords:

-

charcoal maker

-

Capacity:

-

100-3000kg/24h

-

Application:

-

Charcoal Bio Char Production Plant

-

Usage:

-

Carbonize biomass material into charcoal

-

Advantage:

-

High efficiency, energy saving, low cost

-

Carbonization time:

-

6-8 Hours/batch

-

Fuel:

-

Firewood, electricity, natural gas, LPG, coal

-

Steel:

-

Vessel steel

Product Description

Carbonization furnace

▶

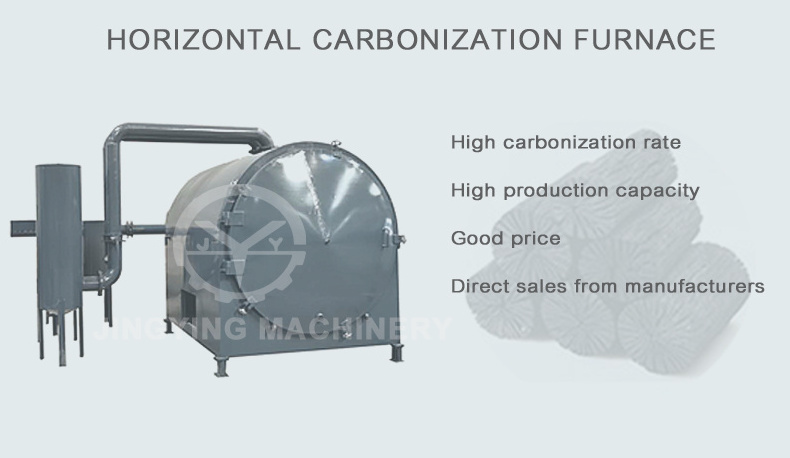

The Jingying series horizontal charcoal furnace is a new kind of air flow type carbonization stove, which can also be called charcoal retort kiln, charcoal making machine, charcoal stove, biochar machine, charcoal maker. It is used to make biochar charcoal from wood, bamboo, coconut shell and all kinds of biomass.

▶

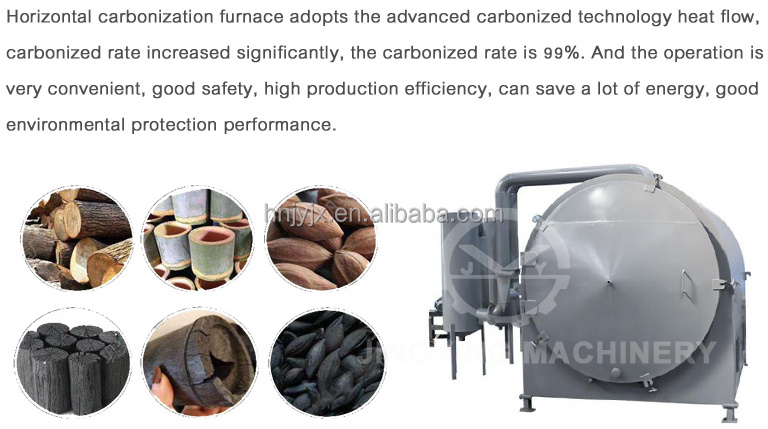

Apply for many kinds of biomass raw materials, such as wood, wood log, tree branch, wood stick, wood waste, wood briquette, coconut shell, bamboo, olive husk, palm kernel shell, cashew nut shell, etc.

▶ This charcoal making machine is e

asy to operate, safety, environmental protection and high production efficiency.

It is the main ideal equipment of the charcoal production line.

Product Parameter

|

Model

|

Inner Size

|

Capacity

|

Dimension

|

Weight

|

||||

|

JYH-1

|

0.5m*1.2m

|

100kg

|

1.8m*0.8m*1.5m

|

300kg

|

||||

|

JYH-2

|

1m*1.5m

|

200kg

|

2.1m*1.3m*1.7m

|

500kg

|

||||

|

JYH-3

|

1.5m*1.5m

|

500kg

|

2.1m*1.8m*2.3m

|

1200kg

|

||||

|

JYH-4

|

1.5m*3m

|

1000kg

|

3.5m*1.8m*2.4m

|

2500kg

|

||||

|

JYH-5

|

1.5m*4.5m

|

2000kg

|

5.2m*1.9m*2.4m

|

3500kg

|

||||

|

JYH-6

|

1.9m*4.5m

|

3000kg

|

5.2m*3.1m*2.4m

|

5000kg

|

||||

|

Other sizes can be customized according to your requirements.

|

|

|

|

|

||||

Product Features

1. Three layers structure of the furnace body.

The inner layer is high heat transfer and wear-resistance steel for increasing the carbonizing temperature. The middle layer is the asbestos for insulation. The outer layer is painted steel.

2. Various heating methods. The heating source can be firewood, coal, l iquefied gas, burner, electric, etc.

3. The door of the furnace is sealed with graphite packing. This can prevent the air from entering the furnace and increase the charcoal yield.

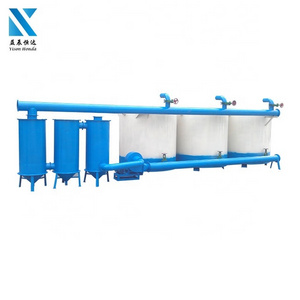

4. Green and energy saving. The purifier tank can clean the smoke generated in the carbonizing. The cleaned gas enters the burning chamber through the pipes and then is ignited to heating the furnace. In this process, no harmful gas is emitted and reduces the consumption of wood, coal, gas, electric, etc for heating.

5. Guide rail and loading basket. They are uniquely equipped for the horizontal carbonizing machine. Workers can load the wood or briquettes into the steel basket and then push it into the carbonizing chamber. This design saves the labor cost a lot and makes the operation easier.

2. Various heating methods. The heating source can be firewood, coal, l iquefied gas, burner, electric, etc.

3. The door of the furnace is sealed with graphite packing. This can prevent the air from entering the furnace and increase the charcoal yield.

4. Green and energy saving. The purifier tank can clean the smoke generated in the carbonizing. The cleaned gas enters the burning chamber through the pipes and then is ignited to heating the furnace. In this process, no harmful gas is emitted and reduces the consumption of wood, coal, gas, electric, etc for heating.

5. Guide rail and loading basket. They are uniquely equipped for the horizontal carbonizing machine. Workers can load the wood or briquettes into the steel basket and then push it into the carbonizing chamber. This design saves the labor cost a lot and makes the operation easier.

Production Line

Charcoal briquette making line

How to make charcoal from sawdust?

1. Wood crusher:

A crusher will help you to reduce the size of your raw material to less than 5 mm.

2.

Dryer: For small capacity drying, you can choose the air flow dryer with small investment. If your capacity is bigger, a rotary dryer will be a better choice.

3.

Wood briquette machine: Press raw material into wood briquettes.

4.

Charcoal furnace: After carbonization, wood sawdust briquettes become smokeless charcoal.

5.

Other accessories: Conveyor, material distributor, etc.

Customer Site

Hot Searches