- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380/415VAC

-

Dimension(L*W*H):

-

750*540*1120mm

-

Power (kW):

-

7.5KW

-

Weight (KG):

-

140 KG

-

Product Name:

-

High Pressure Polyurethane Spray

-

Application:

-

Polyurethane Products Produce

-

Raw material:

-

Polyol

-

Function:

-

Foam Maker

-

Applicable materials:

-

PU Material

-

Color:

-

Customised

-

Automatic:

-

Fully Automatic Production

-

Advantage:

-

High Capacity

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

IDEAL

-

Machine Type:

-

Foam Machinery

-

Voltage:

-

220/380/415VAC

-

Dimension(L*W*H):

-

750*540*1120mm

-

Power (kW):

-

7.5KW

-

Weight (KG):

-

140 KG

-

Product Name:

-

High Pressure Polyurethane Spray

-

Application:

-

Polyurethane Products Produce

-

Raw material:

-

Polyol

-

Function:

-

Foam Maker

-

Applicable materials:

-

PU Material

-

Color:

-

Customised

-

Automatic:

-

Fully Automatic Production

-

Advantage:

-

High Capacity

Professional Polyurea Coating Spray Injection Hydraulic Polyurethane Foam Machine Mini Spray Foam Insulation Machine

A

polyurethane spray machine

, also known as a polyurethane spraying machine, is a specialized equipment used in the application of polyurethane coatings. It is designed to spray or atomize liquid polyurethane materials onto various surfaces to create protective coatings or insulating layers. This machine typically consists of a spray gun, a mixing unit, and a high-pressure pumping system.

Products Description

The polyurethane spray machine is widely used in industries such as

construction, automotive, aerospace, and marine,

where the ability to apply uniform and seamless polyurethane coatings is essential. These coatings can provide corrosion protection, thermal insulation, waterproofing, and enhance overall durability.

|

Model

|

ID-E3

|

|

Voltage

|

110V/220V/380V/415V

|

|

Power

|

7.5KW

|

|

Driving method

|

pneumatics

|

|

Efficiency

|

2-12KG/min

|

|

Max. working pressure

|

11Mpa

|

|

Output ratio

|

1:1

|

|

Max. Hose Support

|

90m

|

|

Dimension

|

750*540*1120mm

|

|

Weight

|

140KGS

|

Product Overview

It can be applied to building roofs, tunnels, railway subgrades waterproofing, foam film and television prop production, internal and external pipeline anti-corrosion, auxiliary cofferdam engineering, corrosion protection of tanks and chemical storage tanks, pipeline coatings, desalination water tanks, waterproofing and anti-corrosion of water tanks, chemical and mining wear resistance, fenders and buoyancy materials, basement waterproofing, cabin wear-resistant lining, external wall insulation, etc.

Especially for intercity rail transit, high-speed railway bridge concrete surface waterproofing, it has advantages over almost all existing materials. It is environmentally friendly, chemically resistant, high in strength, strong impermeability, wear-resistant, thermally stable, flexible, impact-resistant, seamless, and has strong adhesion to concrete.

It effectively simplifies the design layers of waterproofing structures and reduces thickness. Due to its convenient construction process and green environmental characteristics, it demonstrates unmatched advantages compared to traditional waterproofing protection technologies.

Details Images

1. Seamless Coatings: The machine enables the application of seamless polyurethane coatings, eliminating the need for joints or seams, which enhances the overall durability and effectiveness of the protective layer.

2. Versatility: Polyurethane spray machines can be used on a wide range of surfaces, including metals, concrete, wood, and plastics, making them suitable for diverse industrial and commercial applications.

3. Rapid Application: The high-pressure pumping system and efficient spray gun allow for quick and even distribution of polyurethane materials, resulting in faster application and reduced project completion times.

4. Excellent Insulation Properties: Polyurethane coatings applied using this machine offer exceptional thermal insulation, which is valuable for temperature regulation and energy conservation in buildings and industrial equipment.

5. Corrosion Resistance: The protective coatings created by the polyurethane spray machine exhibit excellent resistance to corrosion, protecting the underlying surfaces from environmental and chemical damage.

Gun:

1.Steel friction vice, solves the trouble of frequently disassembling and washing the gun.

2. Advanced continuous air cleaning method with compact structure, flexible operation, and less wearing parts.

3. Lightweight gun body, easy to operate

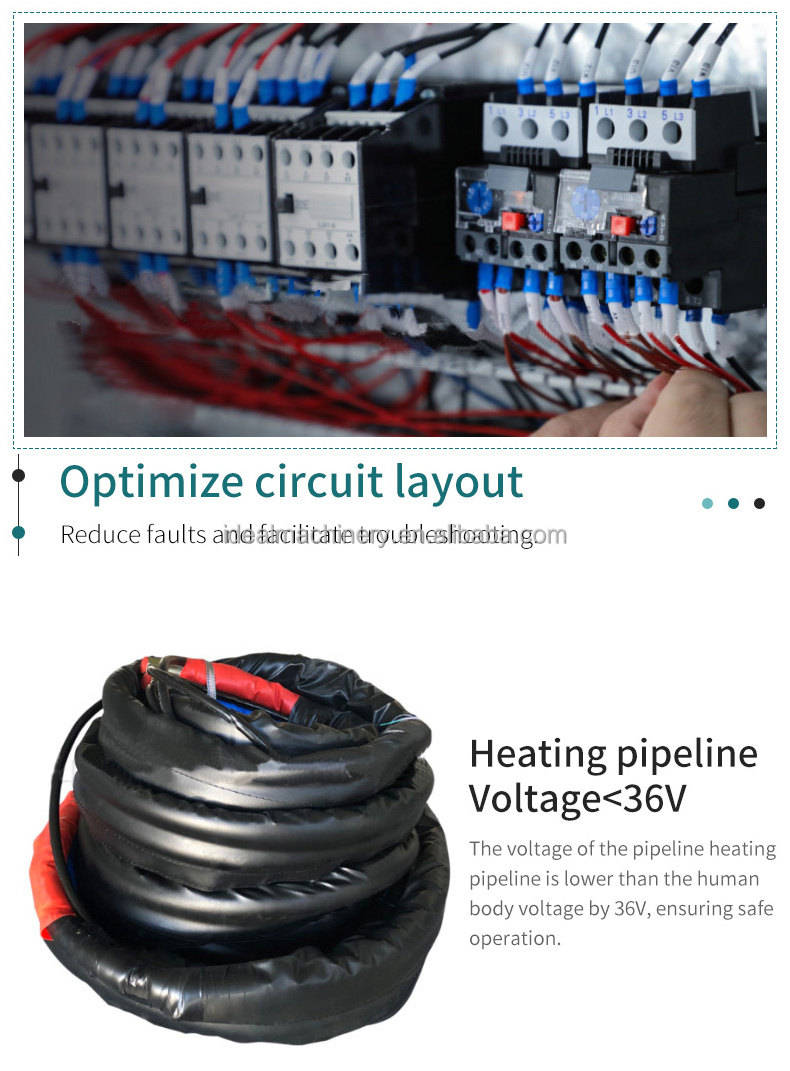

Pipe:

1. Road alloy copper belt spiral winding heating mode, fast heating speed, heat conduction uniformity, stable heating process, sensitive high-quality temperature sensing equipment.

2. Intelligent temperature control pipeline heating system, regardless of the length of the pipeline using a stable and consistent process.

3. The outer layer adopts a nylon protective sleeve to extend the service life of the pipeline.

4. Pipes inside the special multi-layer resin reinforced tube, high strength, easy to move, multi-layer insulation special protective sleeve, reduce heat loss, increase the heating efficiency of the pipeline.

1. Specialized pneumatic feeding system with stable conveying pressure and flow ensures the correct ratio of raw material conveying.

2. The piston sealing ring is designed based on imported technology, with sensitive response, even material supply, and very little leakage and crystallization.

Product packaging

1 unit was packed into an iron frame and then packed with 5 layers of corrugated carton. 4 strips reinforced the carton. the fix package guaranteed the machines were not damaged during transportation

Hot Searches