- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DECHEN

-

Model Number:

-

DC-12AA100-2500

-

Weight (KG):

-

3500

-

Power (kW):

-

380

-

Product name:

-

construction welded wire mesh machine

-

Welding aperture:

-

100*100-300*300mm

-

Wire forms:

-

coil wire

-

Mesh width:

-

2500mm(customzied)

-

Welding speed:

-

40-70times/min

-

Number of electrodes:

-

26(customized)

-

Mesh length:

-

Max.12m

-

Control system:

-

Japan Mistubishi PLC+touch Screen

-

Finished product:

-

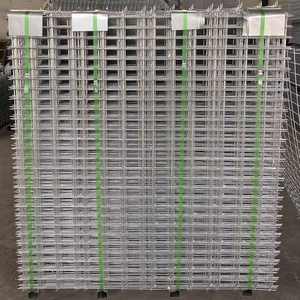

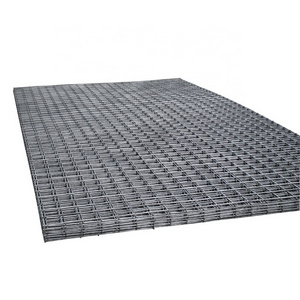

wire mesh sheets

-

wire diameter:

-

5-12mm

Quick Details

-

Wire Diameter (mm):

-

5 - 12 mm

-

Production Capacity:

-

70times/min

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

DECHEN

-

Model Number:

-

DC-12AA100-2500

-

Weight (KG):

-

3500

-

Power (kW):

-

380

-

Product name:

-

construction welded wire mesh machine

-

Welding aperture:

-

100*100-300*300mm

-

Wire forms:

-

coil wire

-

Mesh width:

-

2500mm(customzied)

-

Welding speed:

-

40-70times/min

-

Number of electrodes:

-

26(customized)

-

Mesh length:

-

Max.12m

-

Control system:

-

Japan Mistubishi PLC+touch Screen

-

Finished product:

-

wire mesh sheets

-

wire diameter:

-

5-12mm

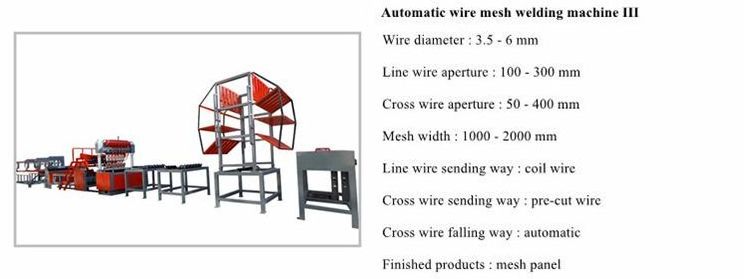

iron electric welded brc wire mesh machine making machine

1.The machine is used for wire diameter 3-10mm, it is an automatic equipment that desiged and manufactured by ourselves . This machine is driven by pneumatic system and composed of line wire support system, water cooling welding transformer, pneumatic control cross wire falling system, servo motor pulling mesh device.

The details of construction welded wire mesh machine

1..Feeding

System

Line wire feeding:

firstly the line wires are sent by automatically coils feeding , when it welding and drawing, labors can prepare the coils wires, it increases the production efficiency.

Cross wire feeding: Firstly, the coil wires are straighten and cut into fixed length by straightening cutting machine, which become weft wire. Then worker put the weft wires into wire hopper. Wire hopper under the control of step motor, the weft wires falling automatically one by one.

2. Control system

The machine uses Janpan Mistubishi or Siemens PLC touch screen control technique , we use Japan, Sony digital control system which can be input to touch screen control panel to adjust the mesh size, so it can weld different mesh size on the same mesh panel .

3.Welding system

T he machine welding system is controled by pneumatic system, which makes the adjusting of welding pressure simple and convenient. At the same time, the welding electrodes are equipped with water cooling system to make sure the welding during a long working time, and prolong the life .

4. Water-cooling system

transformer and water-cooling lower electrodes to make sure the welding firm during a long working time, and prolong the service life.

5 . T he mesh pulling &cutting system is controlled by step motor, which makes the pulling mesh aperture more standard and accurate.

6.Mesh falling system : Automatic falling mesh panel system is adopted, so it save much labor to move the mesh panels.length 12m control by air cylinder .

| Items | DC-12MM-50-2000 | DC-12MM-50-2500 |

| wire diameter | 3-6mm | 4-10mm |

| line wire space | 100-300mm | 100-300mm |

| cross wire space | 50-300mm | 50-300mm |

| wire forms | coils wire feeding | coils wire feeding |

| mesh width | 2000mm | 2500mm |

| number of electrodes | 12 (customzied) | 41(customized) |

| welding speed | 50-70times/min | 50-70times/min |

| C ooling system | W ater cooling transformer | W ater cooling transformer |

| C ontrolling system | Janpan Misibishi PLC touch screen | Janpan Misibishi PLC touch screen |

All the parameters can be customzied according to customers' requirement.

1.Automatic wire straightening and cutting machine --- 2 sets

2.Wire tray --- 2 pcs

3. One set air compressor, one piece of air tank and air dry machine

Application: It can be used for producing high-level construction and bridge mesh, high-way reinforce mesh, construction reinforce mesh, floor pouring mesh, airport reinforce mesh and so on.

Suitable materials: Galvanized wire, stainless steel wire, iron wire and so on.

1.The machine will be packed with plastic films.

2.Some accessories and wearing parts will be packed with wooden box.

3.Shipping within 30 days after receiving your deposit.

1.If the buyers need, we can send our technical staff to the buyers factory to install the machine and providing the training in 30 days after the machines arrived the destination port.

2.Maintenance period :one year for whole machine except vulnerable parts

3.The numbers of technical persons: one technician per machine

4.The fees: the buyer have to pay the technical salary 80 USD per day, and the round-trip ticket, accommodation and other related fees.

During the maintenance period , if the parts are broken caused by the product problem, seller will offer the parts for free, if you need we assign the technicians to your factory, then you will pay some related fees.

If need more information, please click our web: http://dechenmachine.en.alibaba.com