- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

10M*1.2M*1.5M

-

Weight:

-

8000 KG

-

After Warranty Service:

-

Field maintenance and repair service

-

Certification:

-

CE ISO9001

-

width:

-

500mm-2200mm

-

Applied to Materials:

-

non-woven fabrics paper aluminum foil

-

thickness:

-

customized

-

Product name:

-

Laminating Machine

-

final products:

-

lamination machine coating machine

-

Automaticity:

-

220V

Quick Details

-

Voltage:

-

220C/380V/415V/480V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GSmach

-

Dimension(L*W*H):

-

10M*1.2M*1.5M

-

Weight:

-

8000 KG

-

After Warranty Service:

-

Field maintenance and repair service

-

Certification:

-

CE ISO9001

-

width:

-

500mm-2200mm

-

Applied to Materials:

-

non-woven fabrics paper aluminum foil

-

thickness:

-

customized

-

Product name:

-

Laminating Machine

-

final products:

-

lamination machine coating machine

-

Automaticity:

-

220V

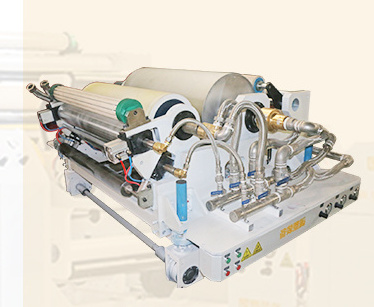

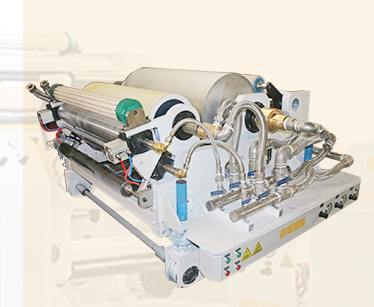

bopp film automatic high speed lamination roll machine

FEATURES AT A GLANCE

Product Overview

The equipment adopts a one-by-one design, the unwinding adopts exchange volume, magnetic powder tension design, constant tension control, and the production acceleration and deceleration speed can be synchronized.Ratio control, edge material crushing online recycling, less production waste, speed can reach 50m\min_100m\min_150m\min three designs

pe laminating roll paper coating extrusion machine machine uses imported electrical components. The central control unit mainly adopts the German SIEMENS-CPU-315 series or better than the above; the human-machine interface selects the German SIEMENS-TP270;

the temperature control unit adopts the CPU temperature control module; the extruder Siemens Beide's high-performance governor;

The speed of the film machine is imported and controlled by the field bus. The line speed can be adjusted between 0 and 50 m/min.

The high-performance vector speed controller of Siemens Beide is used for winding. The specific parameter setting can be realized by touch screen.

the temperature control unit adopts the CPU temperature control module; the extruder Siemens Beide's high-performance governor;

The speed of the film machine is imported and controlled by the field bus. The line speed can be adjusted between 0 and 50 m/min.

The high-performance vector speed controller of Siemens Beide is used for winding. The specific parameter setting can be realized by touch screen.

|

Equipment model

|

800/1000/1600/2000

|

|

Product width (mm)

|

800/1000/1600/2000

|

|

Product thickness (mm)

|

0.015-0.2mm

|

|

Max line speed m/min

|

100m

|

Application area

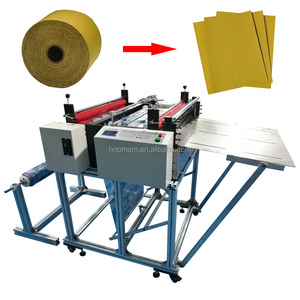

pe laminating roll paper coating extrusion machine machine is suitable for general plastics, engineering plastics, special

engineering plastics and other equipment.Customization. It consists of a single-layer, double-layer, multi-layer co-extruded cast film extrusion line.The whole set of equipment is designed and developedby Nanjing Guosu Extrusion Equipment, and the extrusion system uses a metering pump.Closed-loop control can effectively stabilize the film formation and uniform

thickness.Multi-layerSqueeze with a distributor for stratification, including AB\ABA\ABC\ABCBA\ABCDCBA

engineering plastics and other equipment.Customization. It consists of a single-layer, double-layer, multi-layer co-extruded cast film extrusion line.The whole set of equipment is designed and developedby Nanjing Guosu Extrusion Equipment, and the extrusion system uses a metering pump.Closed-loop control can effectively stabilize the film formation and uniform

thickness.Multi-layerSqueeze with a distributor for stratification, including AB\ABA\ABC\ABCBA\ABCDCBA

|

Processing Material

|

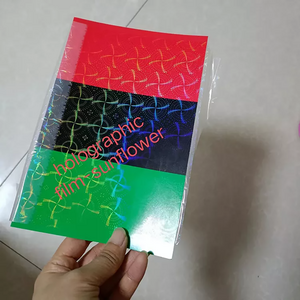

paper, moisture-proof, disposable clothing

|

|

|

|

|||

|

Final Porduct

|

laminated paper, moisture-proof, disposable clothing

|

|

|

|

|||

|

Application

|

packaging , clothes, etc

|

|

|

|

|||

|

Capacity

|

60-150m/min

|

|

|

|

|||

|

Technology & Training

|

Available

|

|

|

|

|||

PRODUCT CONFIGURATION

|

Machine Composition

|

|

|

|

|

||||

|

Model

|

Machine

|

|

|

Quantity

|

||||

|

1

|

Double station unwinding system

|

|

|

1 set

|

||||

|

2

|

Vacuum screw feeder

|

|

|

1 set

|

||||

|

3

|

Hopper dryer

|

|

|

1 set

|

||||

|

4

|

Single screw extruder

|

|

|

1 set

|

||||

|

5

|

Single board single station filter

|

|

|

1 set

|

||||

|

6

|

Solution static mixer

|

|

|

1 set

|

||||

|

7

|

Laminating Special Mould

|

|

|

1 set

|

||||

|

8

|

Laminating composite molding system

|

|

|

1 set

|

||||

|

9

|

Online Infrared Detection System

|

|

|

1 set

|

||||

|

10

|

Correction device

|

|

|

1 set

|

||||

|

11

|

Fabric static elimination device

|

|

|

1 set

|

||||

|

12

|

Tractor

|

|

|

1 set

|

||||

|

13

|

Double station automatic winding system

|

|

|

1 set

|

||||

|

14

|

SIEMENS human-machine interface control system

|

|

|

1 set

|

||||

Laminating composite system

Double station winding system

Solution static mixer

Material rewinding→ Corona→ Tractionroller coated →Traction → Drying → Deflection → Flip→Spray→Drying→ Edge→Four cylinder thermal shaping→ rewinding

The characteristics of the machine

:

-----The rewinding volume using the upper and lower cutting mode, can adapt to the requirements of different process coating level.

-----Speed 150m/min, change the winding non-stop machine, do not slow down, tension stability.

-----The bottom coating using three-roller transfer coating, coating amount by precision ball screw quasi-adjustment, accurate and

reliable. Can be adapted to a relatively wide range of coating changes.

-----surface coating using extrusion spraying coating head, uniform coating, clean and clean coating, coating quality is stable.

-----the oven adopts the step mussel design structure, the installation is convenient, the paper is on the transition roller. The

package angle does not change due to installation errors and the structure is stable. Special septum of the inner gall. Thermal

design, low energy consumption.

-----The rewinding volume using the upper and lower cutting mode, can adapt to the requirements of different process coating level.

-----Speed 150m/min, change the winding non-stop machine, do not slow down, tension stability.

-----The bottom coating using three-roller transfer coating, coating amount by precision ball screw quasi-adjustment, accurate and

reliable. Can be adapted to a relatively wide range of coating changes.

-----surface coating using extrusion spraying coating head, uniform coating, clean and clean coating, coating quality is stable.

-----the oven adopts the step mussel design structure, the installation is convenient, the paper is on the transition roller. The

package angle does not change due to installation errors and the structure is stable. Special septum of the inner gall. Thermal

design, low energy consumption.

Hot Searches