- Product Details

- {{item.text}}

Quick Details

-

Power:

-

OH-300-4:Main Pump 18.5KW

-

Dimension(L*W*H):

-

OH-300-4:7100*5400*3400

-

Weight:

-

7500 KG

-

Production Capacity:

-

250-300kgs per tube

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine Type:

-

HT Fabric Dyeing Machine

-

Stainless steel:

-

SS316L

-

Low Liquor Ratio:

-

1:3.5~4.5

-

Max Working Temperature:

-

140 deg.C

-

Max Working Pressure:

-

0.36Mpa

-

Operating Speed:

-

450m/minute

-

Plaiting System:

-

X-Y

-

Controller:

-

EPC or SETEX 787TCE +PLC

Quick Details

-

Voltage:

-

380V/50Hz(Optional)

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SUNSKY

-

Power:

-

OH-300-4:Main Pump 18.5KW

-

Dimension(L*W*H):

-

OH-300-4:7100*5400*3400

-

Weight:

-

7500 KG

-

Production Capacity:

-

250-300kgs per tube

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine Type:

-

HT Fabric Dyeing Machine

-

Stainless steel:

-

SS316L

-

Low Liquor Ratio:

-

1:3.5~4.5

-

Max Working Temperature:

-

140 deg.C

-

Max Working Pressure:

-

0.36Mpa

-

Operating Speed:

-

450m/minute

-

Plaiting System:

-

X-Y

-

Controller:

-

EPC or SETEX 787TCE +PLC

OH/UH series low liquor ratio high-temperature high pressure HTHP overflow fabric dyeing machine applicable to various of fabrics:Cotton,Modal,Viscose,Tencel,Rayon,Wool,Acrylic,Lyocell,Nylon,Polyester blended and lycra blended. With a specially-designed nozzle structure, it enables the fabrics in loose and expanded conditions during the dyeing process. It has an excellent performance in dyeing tight and heavy fabrics and can eliminate the crease mark problem, which is usually seen in other dyeing machines.Two ropes loading capability.

- Low Liquor Ratio; 1:3.5~4.5 at full load

- Operating Speed: 450M per minute

- Maximum working temperature: 140' C

- Maximum working pressure: 0.36Mpa

- Temperature increase rate: 5' C per minute on average from 25 to 100' C, 2.5 0 C per minute on average from 100 – 130' C (Pressure of dry saturated vapor: 0.7Mpa)

- Temperature deduction rate: 3' C per minute on average from 130 to 100' C, 2' C per minute on average from 100 to 85' C (Cooling water pressure: 0.3Mpa, 25' C).

| Model | Nrs of Tubes | Load (KG) | Length(mm) | Width(mm) | Height(mm) | MainPump | Running Power(KW) |

| Power(KW) | |||||||

| OH-300-1 | 1 | 300 | 3500 | 5400 | 3400 | 5.5 | 13 |

| OH-300-2 | 2 | 600 | 4800 | 5400 | 3400 | 7.5 | 19 |

| OH-300-3 | 3 | 900 | 5900 | 5400 | 3400 | 15 | 26 |

| OH-300-4 | 4 | 1200 | 7100 | 5400 | 3400 | 18.5 | 34 |

| OH-300-6 | 6 | 1800 | 9500 | 5400 | 3400 | 37/45 | 47 |

| OH-300-8 | 8 | 2400 | 12500 | 5400 | 3400 | 45 | 56 |

Execellent Performance by using new technologies

- The vertical heat exchanger enables the condensated water to be drained instantly and reduces time in the shifting between hot and cold water.Also,it can avoid the formation of water scale,extend the service life of heat exchanger.

- The inlet pipe of the main pump is optimized,the height of water inlet is lowered and hence the water consumption is reduced significantly.

- The U-shaped fabric tank and synchronized fabric plaiting system increase the loading capacity by 20%,meanwhile,by plaiting in multiple directions,tangling problems can be completely avoided.

- Leading dyeing control system,in combination with dually balancing flow feeding system and constant pressure and stable flow rate,a uniform dyeing is guaranteed.

- The height of machine and operation platform is lowered and size of the operation platform is reduced,making operation much more convenient.The bottom of dye vat is specially designed so as to reduce water storage and lower liquor ratio effectively.

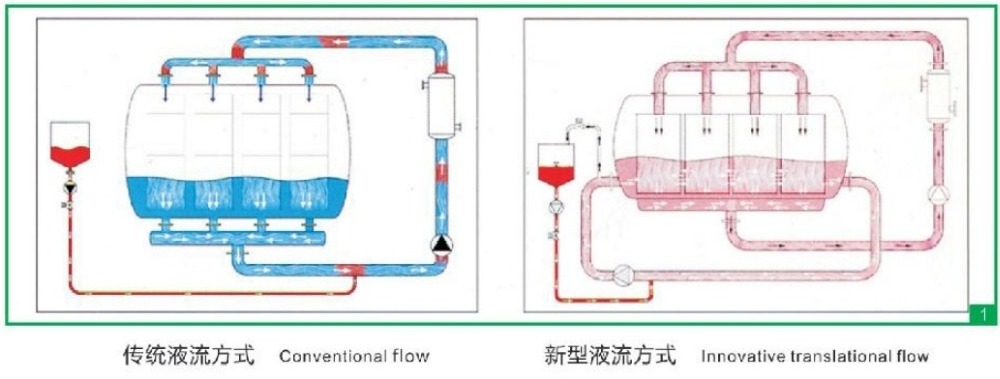

- With unique main vat circulation system,the temperature difference of entire dye vat from top and bottom and evennessof feeding is controlled at optimum conditions.

- Rotating spray is adopted from main vat cleaning and the whole vat is within the range of cleaning,ensuring a thorough cleaning.

- Dye liquor runs longitudinally,Longitudinal running of dye liquor and multidirection suction system greatly reduces the liquor ratio and optimizes the evenness of dye liquor.

Eco-friendly,energy saving and high-efficiency

- The low liquor ratio reduces the water consumption greatly.

- Comparing with traditional dyeing machine,the salt,auxiliary and steam consumption can be saved by 50%

- Lowest installed power,hence lowest electrical energy consumption.

- Fast dyeing cycle,enhanced productivity.

- User-friendly operation and easy maintenance.