- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

100 KG

-

Dimension(L*W*H):

-

Custom

-

Product Name:

-

double-pipe heat exchanger

-

Function:

-

Heat Exchanger

-

OEM:

-

Customization

-

Material:

-

SS304/316

-

Usage:

-

cooling, distillation, distillation, concentration

-

Heat exchanger type:

-

multiple media heat exchange

-

Application:

-

food, energy electronics

-

After Warranty Service:

-

Video technical support;Online support

-

Local Service Location:

-

Canada;United States;Viet Nam;Indonesia

-

After-sales Service Provided:

-

Free spare parts;Video technical support

Quick Details

-

Structure:

-

Tubular Heat Exchanger

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Prettech

-

Weight:

-

100 KG

-

Dimension(L*W*H):

-

Custom

-

Product Name:

-

double-pipe heat exchanger

-

Function:

-

Heat Exchanger

-

OEM:

-

Customization

-

Material:

-

SS304/316

-

Usage:

-

cooling, distillation, distillation, concentration

-

Heat exchanger type:

-

multiple media heat exchange

-

Application:

-

food, energy electronics

-

After Warranty Service:

-

Video technical support;Online support

-

Local Service Location:

-

Canada;United States;Viet Nam;Indonesia

-

After-sales Service Provided:

-

Free spare parts;Video technical support

Product Introduction

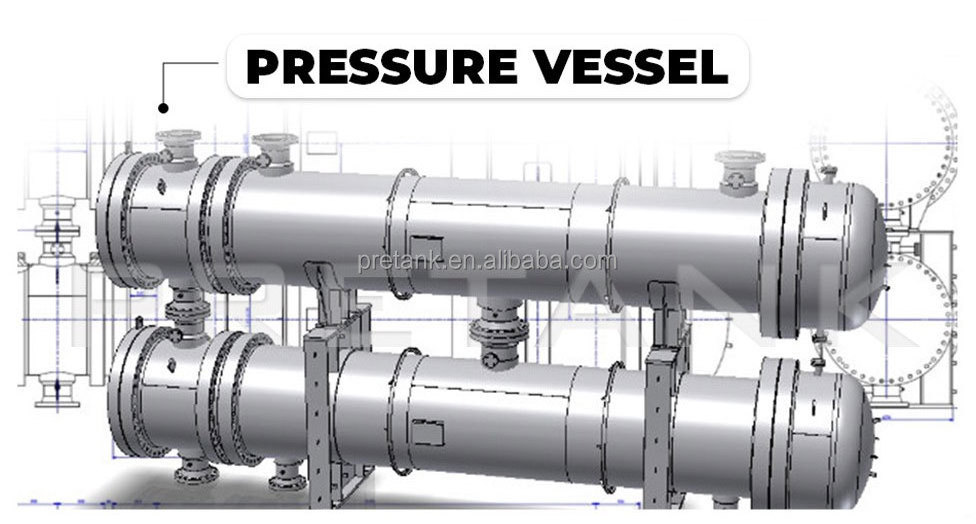

SHELL&TUBE HEAT EXCHANGER

DESIGN AND FABRICATIONA

As its name implies, this type of heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids.it can be used for for evaporation, condensation, heating, cooling and heat recover,and is suitable for high pressure applications.

GB/T 151,ASME,PED,EAC certificate provided.

Application

This heat exchanger is widely used in chemical industry, power generation, HVAC and refrigeration, oil and gas, compressor cooling, marine applications, pulp and paper, metals and mining, etc.

Product Paramenters

All three types of Shell & Tube Heat Exchangers, including Fixed tubesheet type, U-tube type and Floating tubesheet type, in a variety of metals including

Carbon Steel Q235B/Q345R, Stainless Steel 304/316, Nickel Alloy,titanium,graphite

etc.

Fixed tubesheet heat exchanger

has straight tubes secured at both ends to the stationary tube sheets that are welded to the shell.This kind of heat exchanger is applicable to all services where the temperature difference between the shell and tube is small.

U-tube heat exchanger

is a

kind of tube and shell heat exchanger, belongs to the petroleum and chemical equipments. This kind of heat exchanger is named after the 'U' shape tube.This kind of heat exchanger has a light quality, is suitable for the situation with high temperature and high pressure.

Floating head heat exchanger

is one end of the tubesheet is fixed to the shell, while the other one can “float” freely inside the shell. Floating head heat exchanger is widely used for the service where the temperature is high between the shell and tube bundle, or the dirty service, like the petroleum refinery.

Product Details

This heat exchanger is consists of

shell,ends,tubesheet,tube bundle,tie rob,spacer pipe,baffle plate etc

.

The baffle plate

is a plate designed to restrain or regulate the flow of fluid,used for supporting and fixing the tubes in a defined position.

The tie rods and spacer pipes

are used to hold the tube bundle together and to locate the shell baffles in the correct position.

The heat transfer area range from 0.5㎡ to 300 ㎡,the specifications are tailored,please send your RFQ for more details. Meanwhile,we also supply plate heat exchanger,reactor,hot water tank,dissolving tank,alkali tank,vaccum buffer tank,sterilizing tank and CIP system.If you need them please inquire particularly.

All of the configuration can be customized according to your requirements.

DESIGN SOFTWARE

The heat exchanger design by

SW6-2011 and PV Elite

. Thermal Rating Calculation Software and Pressure Vessel Mechanical Design Software.

WELDING

All welds are completed by

professional welders with

special equipment welder certificate

to ensure the integrity of pressure vessels.,and can use

strength expansion and stick expansion

.

Related Products

Please send your RFQ for more details. Meanwhile,

we also supply plate heat exchanger,reactor,IBC tote,hot water tank,dissolving tank,alkali tank,vaccum buffer tank,sterilizing tank and CIP system.

If you need them please inquire particularly.

About Us

Jiangsu Pretank Process Co.,Ltd

Prettech has been serving in stainless steel vessels design, producing and installation since 1971, we gather pretty rich experi

ences and projects in varied 40 industries such as food&beverage, chemical,edible oil,water treatment,protein separation and grain treatment, with the support of morden laser machines,advanced technology principle,qualified certificate,we cover 12,000 customers in China and abroad,and the sales turnover come up to USD200 million. Prettech is a reputed and trusted enterprise,customer swould feel satisfactory to work with us.

Certificate

Packing&Shipping

All heat exchanger are packed in wooden box, and wrapped by crashproof blanket,to make sure the goods would be shipped to the clients in the most perfect condition.

Quality control

Pretank pay special attention to quality management and control, avoid any defects and faults before delivery the reactors/tanks to the clients.

1.We are certified by ISO9001 system,all departments from technology, purchasing, production to inspections are managed well in order.

2.All welding and polishing workers are qualified and rookie trained well before they start to work in our company.

3.All stainless materials are purchased from first quality steel mills, their qualified MTC is supplied and Pretank ourself would inspect again before put in our warehosue, includding accessories and fittings.

FAQ

Q1.

How can you guarantee the raw material quality?

We always buy high quality materials from Baosteel or POSCO in order to guarantee the stainless have good processing performance,make sure the standard content of nickle and chrome, we will supply MTC made by both Baosteel and Prettech.

Q2. How do you ship the goods?

We usually ship by sea in containers or flat rack.

Q3. Are you factory or trading company?

We are a manufacturer and export by ourselves.

Q4. Can your factory produce according to our samples or drawing?

Yes,we can do OEM and customization.

Q5. What is your nearest port?

Qingdao port,China

Q6. Do you supply door to door shipping?

Yes we do, Pretank do ocean shipping, customs clearance, import procedures and deliver products to the appointed place.

Q7. How do you guarantee this machine normally operating?

Every machine is tested in our factory before shipping, We will adjust the machine to optimal effect before delivery. And spare is always available and free for you in warranty year.

Q8. Do you supply after-sale services?

Yes we do, if any defects occurred, Pretank would give instructions on how to handle, fast repair locally is available if needed.

Q9. What inspections will you do before delivery in your factory?

All tanks would be tested by static pressure test, dye penetration or X-ray test if requested.

Q10. What is your

warranty

time?

One year for main heat exchanger,6 months for parts.

Hot Searches