- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

customized

-

Weight (KG):

-

5000

-

Power (kW):

-

5

-

Application:

-

Metal wire welding

-

Product name:

-

wire mesh welder

-

Keywords:

-

mesh welding machine

-

power:

-

5kw

-

Continuous working time:

-

24h

-

After-sales Service Provided:

-

Online Support

-

Type:

-

Automation

-

Voltage:

-

Customer's Requirement

-

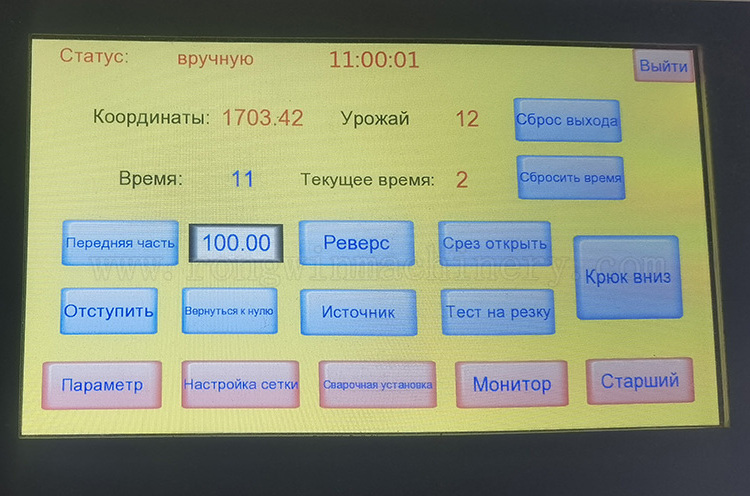

Control system:

-

PLC+touch Screen

-

Usage:

-

Welding Steel Mesh

Quick Details

-

Wire Diameter (mm):

-

2 - 12 mm

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

China

-

Model Number:

-

customized

-

Weight (KG):

-

5000

-

Power (kW):

-

5

-

Application:

-

Metal wire welding

-

Product name:

-

wire mesh welder

-

Keywords:

-

mesh welding machine

-

power:

-

5kw

-

Continuous working time:

-

24h

-

After-sales Service Provided:

-

Online Support

-

Type:

-

Automation

-

Voltage:

-

Customer's Requirement

-

Control system:

-

PLC+touch Screen

-

Usage:

-

Welding Steel Mesh

Product Overview

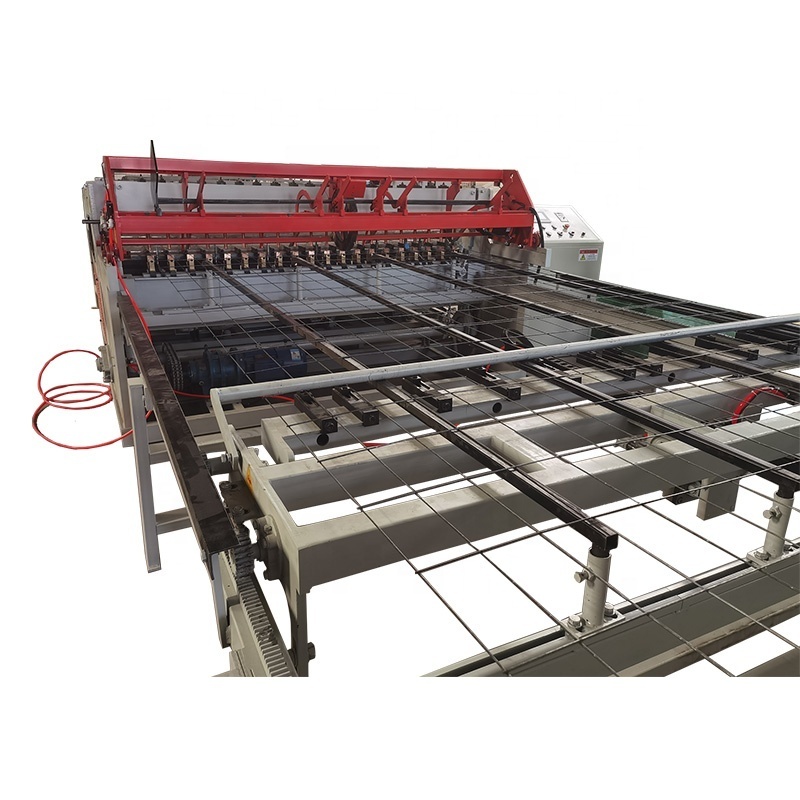

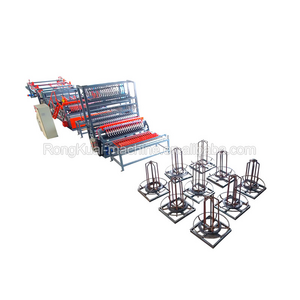

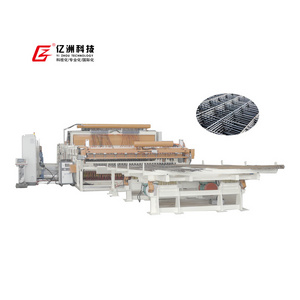

Customized Resistance Spot Welder Wire Mash Welding Foot Pedal Equipment Welding Machine for Metal Sheet Nuts

Uses: It can be used in the production and manufacture of coal mine support nets, fence nets, steel bridge nets for high-rise buildings, steel mesh for roads, steel mesh for buildings, and nets for floor pouring roofs.

Our Advantages

1. Each group of transformers of this welding mesh machine is controlled by a separate microcomputer, which can be welded multiple times at one time. The biggest advantage of this control is that more than 30 holes of different sizes between weft and weft can appear on a mesh.

2. The welding electric head of the welding mesh machine is made of chromium pick copper material, which has a long service life and reduces production costs.

3. The diameter feeding method of this welding machine: automatic wire feeding function for diameter wire. The position is accurate, saving welding waiting time.

4. The weft feeding method of the welding mesh machine: the weft wire hopper automatically feeds and feeds the weft, and the blanking position is accurate.

5. The netting method of this welding machine: adopt servo motor to reciprocate netting, pneumatically tighten weft, and netting position.

6. The welding machine's chipping method: fully automatic mesh conveying mechanism, automatic mesh coding, neatly stacked mesh, and convenient transportation. Reduce manpower and material resources.

PRODUCT CONFIGURATION

Language switchable, touch screen

Chromium-copper alloy welding column head is used,which is more durable and high temperature resistant

The weft wire feeding adopts a new type of large turntable electric funnel, the feeding is accurate and the drop point is accurate

Adopt domestic first-class brand, professional laser chiller, good stability.

System control automatic cut-off

PRODUCT SPECIFICATIONS

|

Wire diameter

|

3-6mm

|

4-8mm

|

6-12mm

|

||

|

Hole size

|

50-200mm

|

100-300mm

|

100-300mm

|

||

|

Width

|

Customized

|

|

|

||

|

Length

|

Customized

|

|

|

||

Related Products

Hot Searches