- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SHENGYIDA

-

COLOR:

-

black

-

Size:

-

Customized

-

Feature:

-

Waterproof,

-

Sintering Method:

-

Hot Pressed, Pressureless Sintered, etc

-

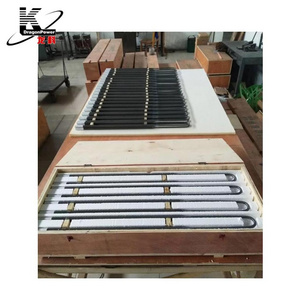

Transport Package:

-

Plastic Foam + Carton

-

Production Capacity:

-

8000 Pieces Per Month

Quick Details

-

SiC Content (%):

-

99%

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

Customized

-

Brand Name:

-

SHENGYIDA

-

COLOR:

-

black

-

Size:

-

Customized

-

Feature:

-

Waterproof,

-

Sintering Method:

-

Hot Pressed, Pressureless Sintered, etc

-

Transport Package:

-

Plastic Foam + Carton

-

Production Capacity:

-

8000 Pieces Per Month

Dongguan Shengyida Hardware Products Co., Ltd. was established in 2008, focusing on research and development Production of ceramic products, hardware products and other precision parts. widely used in automobile, medical, electricity power, electronics,electrical appliances, sanitary ware, aquarium, home appliances and other fields.

The types of ceramic parts produced by the company are ceramic bearings, ceramic tubes, sand grinding machine structural parts,ceramic plungers, ceramic rods, ceramics porcelain plate, ceramic ring, ceramic ball valve, fruit knife, wire trough;ceramic materials are alumina, zirconia, carbon silicon nitride, silicon nitride. accept OEM,ODM,OBM services.

——PRODUCT DESCRIPTION——

The Description Of S

ilicon Carbide Ceramics

Silicon carbide ceramics have excellent mechanical properties, excellent oxidation resistance, high wear resistance and low friction coefficient. The biggest feature of silicon carbide is high temperature strength, ordinary ceramic materials at 1200 ~ 1400 degrees Celsius strength will be significantly reduced, while silicon carbide at 1400 degrees Celsius bending strength is still maintained at a higher level of 500 ~600MPa, so its working temperature can reach 1600 ~ 1700 degrees Celsius.

1.

High abrasion resistance

Silicon carbide has very similar properties to diamond - it is one of the lightest, hardest and strongest technical ceramic materials, with excellent thermal conductivity, acid resistance and low thermal expansion. When physical wear is an important consideration, silicon carbide is an excellent material because it has good corrosion and wear resistance.

2. H

igh temperature resistance

The density of various sic crystals is similar, usually 3.20 g/mm³. Silicon carbide has a hardness of 9.5 Mohs and a Knox hardness of 2670-2815 kg/mm, higher than corundum in abrades, second only to diamond, cubic boron nitride and boron carbide. The thermal conductivity and thermal shock resistance of silicon carbide ceramics are very high, and the thermal expansion parameters are small, so silicon carbide ceramics is a high-quality refractory material.

3.

Chemical corrosion resistance

When the temperature in the oxygen reaction reaches 1300 ° C, a protective layer of silica is formed on the surface of the silicon carbide crystal. With the thickening of the protective layer, the internal silicon carbide is resistant to continue to combine, so that silicon carbide has good chemical resistance.

|

Material options

|

Zirconia, Silicon carbide,Alumina ( purity from 40% to 99.8%), Silicon nitride

|

|

Forming methods

|

Extrusion, Dry pressed, Hot pressed, Ceramic Injection molding, ISO pressed

|

|

Surface treatment

|

External and internal surface to be polished, glazed or metalized

|

|

Secondary processing

|

CNC machining, lapping, threaded, drilling, grinding, precision laser cutting

|

——

Why Choose Us

——

Our advantage and strength

1.Own in-house comprehensive types of manufacturing equipment from raw material to precision machining.

2.With over 10 years of manufacturing experience of OEM, ODM,OBM, and professional and teams.

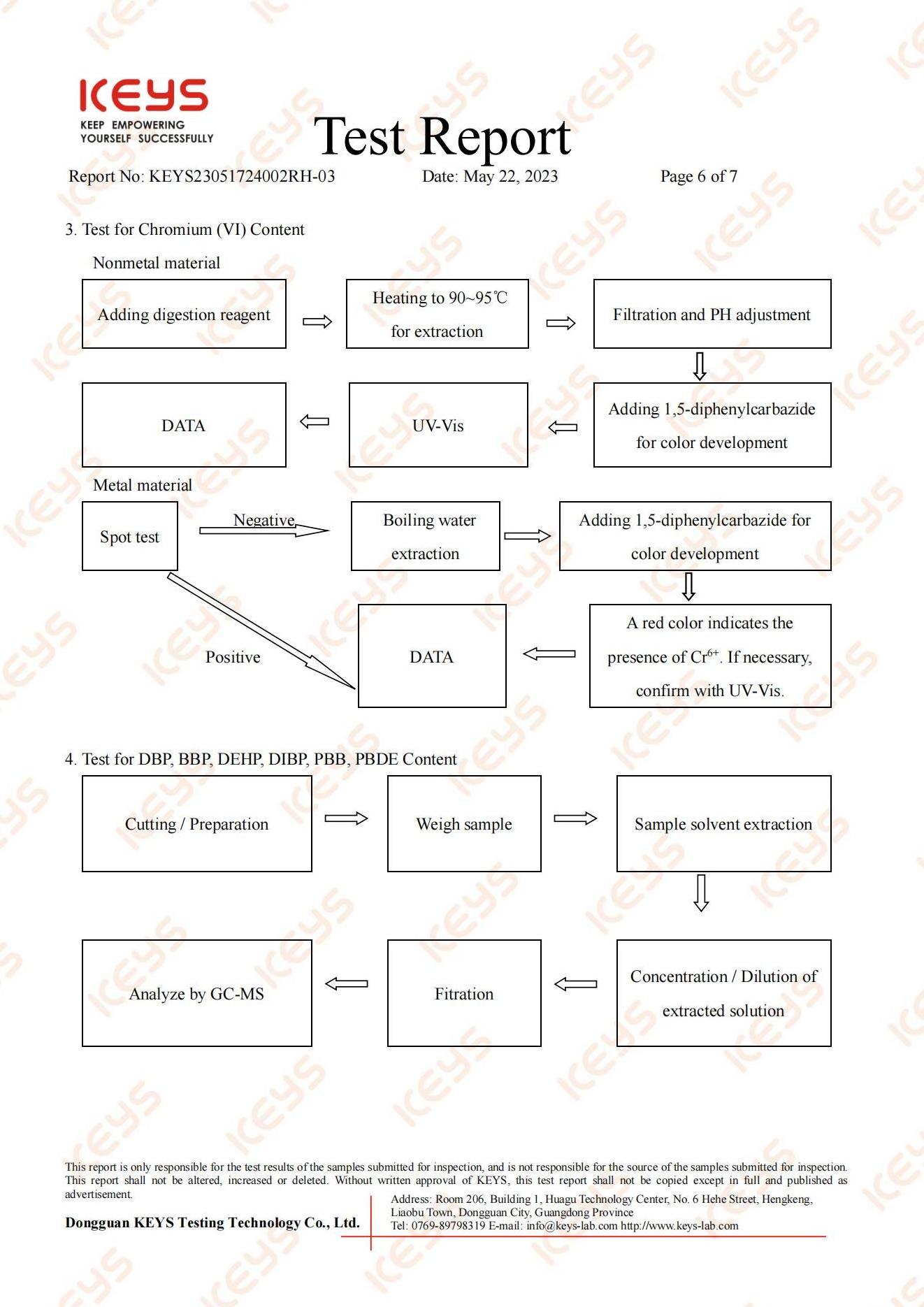

3.The rigorous and complete quality control system, including IQC, IPQC, OQC, and QA, also CPK, AQL.

4.Support special and custom-made needs, including prototyping and R&D cases, or serial massive demands.

5. Offer many selections of technical ceramic materials, including alumina, zirconia, silicon carbide, silicon nitride.

6. Deal with every case in order to enhance the competitiveness of customers and make their business growth.

7. Providing one-stop ceramic components, including Ceramic Tubes, Ceramic Rods, Industrial Ceramic Plate.

Customized service

We support numerous customized services to our clients as per their specific needs, like different materials, different shapes,different surface quality, different dimension accuracy.

——TRANSPORTATION——

——FAQ——

Q1. Do you offer samples?

A: Yes, we'll offer you samples if we have stock, but some will charge sample fee. Shipping cost will pay by customer.

Q2. What is your terms of payment?

A: T/T in advance, Western Union, Alipay, Paypal.

Q3.When can I get the price after sending the inquiry?

A: We regularly quote within 24 hours after we get your inquiry.If you are in urgent need of getting the price,

Please call us or tell us in your email so that we will proceed with your inquiry as a priority.

Q4. How about your delivery time?

A: Depends on the requirement of the producst, according to the materials, dimensions and the manufacture process.

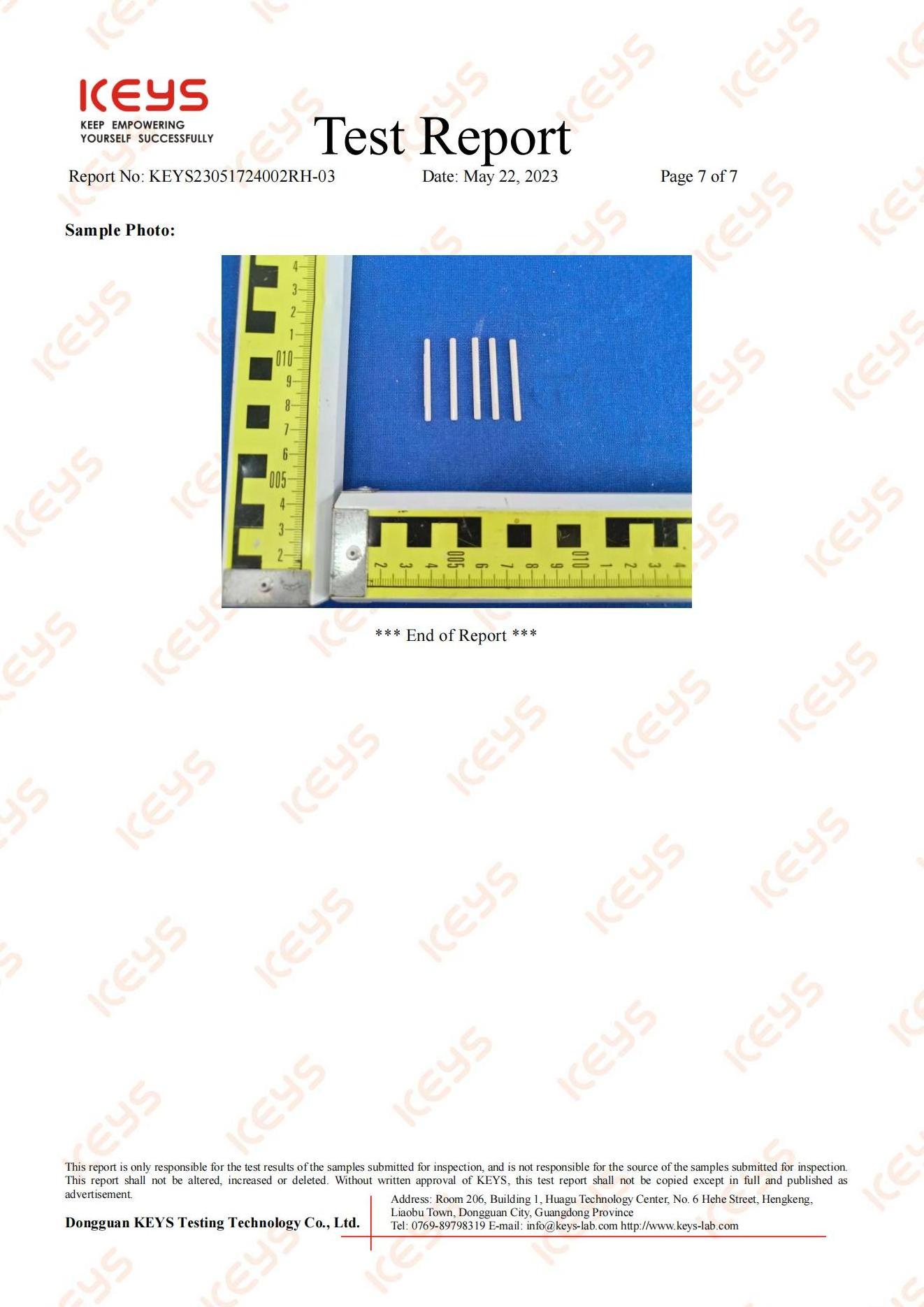

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

A: Yes, we'll offer you samples if we have stock, but some will charge sample fee. Shipping cost will pay by customer.

Q2. What is your terms of payment?

A: T/T in advance, Western Union, Alipay, Paypal.

Q3.When can I get the price after sending the inquiry?

A: We regularly quote within 24 hours after we get your inquiry.If you are in urgent need of getting the price,

Please call us or tell us in your email so that we will proceed with your inquiry as a priority.

Q4. How about your delivery time?

A: Depends on the requirement of the producst, according to the materials, dimensions and the manufacture process.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Hot Searches