- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hubei, China

-

Wavelength:

-

1080nm

-

Dimensions:

-

1300X650X1100mm, 1300X650X1100mm

-

Weight (KG):

-

150 KG

-

Laser device:

-

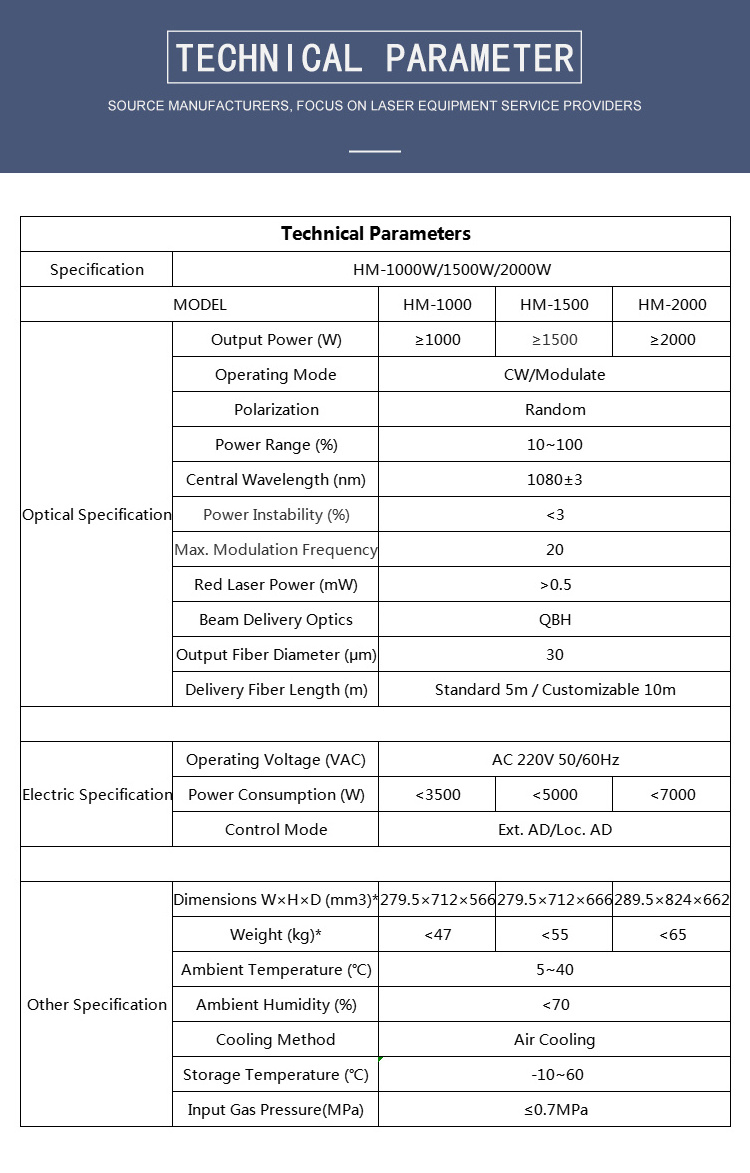

1000W/ 1500W / 2000W

-

Laser wave length:

-

1080nm

-

Welding speed range:

-

0-120mm/s

-

Fiber length:

-

Standard 15m

-

Water cooling:

-

Special for handheld welding

-

Electromechanical:

-

380V/50HZ or 220V optional

-

Total power:

-

6KW

-

Total weight:

-

150KG

Quick Details

-

Max. Output Power:

-

2000W

-

Usage:

-

laser welding machine

-

Laser Source Brand:

-

RAYCUS

-

Place of Origin:

-

Hubei, China

-

Wavelength:

-

1080nm

-

Dimensions:

-

1300X650X1100mm, 1300X650X1100mm

-

Weight (KG):

-

150 KG

-

Laser device:

-

1000W/ 1500W / 2000W

-

Laser wave length:

-

1080nm

-

Welding speed range:

-

0-120mm/s

-

Fiber length:

-

Standard 15m

-

Water cooling:

-

Special for handheld welding

-

Electromechanical:

-

380V/50HZ or 220V optional

-

Total power:

-

6KW

-

Total weight:

-

150KG

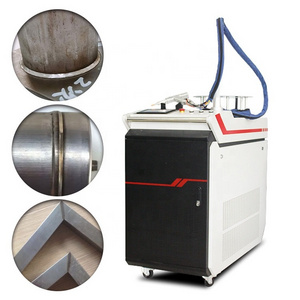

Handheld fiber laser welding can be used in welding stainless steel, aluminum, copper, gold, silver, chromium, nickel, titanium and other metals or alloys, can also be used for a variety of welding between different materials, such as: copper – brass, titanium –gold, Titanium – molybdenum, nickel – copper and so on.

Welding range: 0.5~8mm carbon steel,0.5~4mm stainless steel, aluminium alloy 0.5~6mm, brass 0.5~4mm.

Main Feature

1.The system is mainly composed of a laser unit and a welding unit.

2.Hand-held welding, taking into account the flexibility, high efficiency and high weld quality of laser welding.

3.Modular design and layout of the overall equipment, beautiful and easy to maintain and debug.

4.High system flexibility, compatible with a variety of models, and short changeover time.

5.The internal design is dexterous, and the good interactive control system expands the tolerance range of the machined parts and the weld width, solves the disadvantage of small spot size, and welds are better formed.

6.The shape is light, the body engineering design method is adopted, and the grip is comfortable; the hand is easy to control, and the operation is simple and easy to use.

7.With multiple safety alarms, the light is automatically locked after the workpiece is removed, and the safety is high.

8.Beautiful weld seam, fast speed, no consumables, no weld marks, no discoloration, no need for post-grinding.

9.Can be equipped with a variety of angle nozzles to meet the welding needs of different products.

1. Delivery time:

7-15 days delivery time for standard machines 15-30 days for machines that have been customised to client specifications.

2. Payment terms:

30% deposit payable upon acceptance of quotation 70% balance of invoice due before shipping.T/T, west union are approved methods of payment.

3. Shipping:

Good can be shipped by either of the methods below: FOB or CIF, shipped by our ship partner. for EX.W, shipped by you or your agents.

4. Machine Operational Instructions:

The following options are available to customers: an instructional video demonstrating how to use the machine .a complimentary free training session hosted at our factory, pending availability. an operating manual ( english) is provided with the machine.

5. Guarantee & After-Sales Service:

The machine comes with a 12 month guarantee. a 24 hour, free technical support service is available via email, fax, MSN, skype, phone, tradeMessenger.

6. Product Warranty:

Replacement parts will be supplied at no cost for the period of the warranty. replacement parts are at the customers expense after this expiry of the warranty period. however, we guarantee customer support within 48 hours of being notified of an issue, to support product maintenance.

7. Minimum Order Quantity (MOQ):

We accept single (1) machine orders.